Hardware cast iron die-casting stamping die

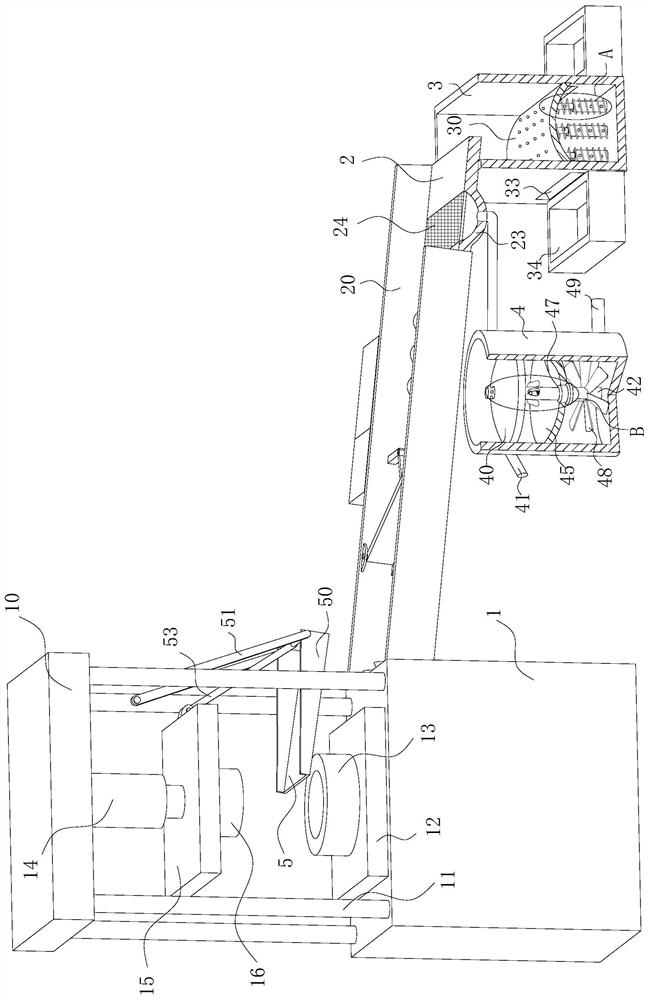

A stamping die and cast iron technology, which is applied in the field of metal cast iron die-casting stamping dies, can solve problems such as the reduction of die precision and service life, the increase of die and workpiece damage rate, and the drop of workpieces, so as to improve the accuracy and service life and improve production The effect of improving work efficiency and improving product qualification rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

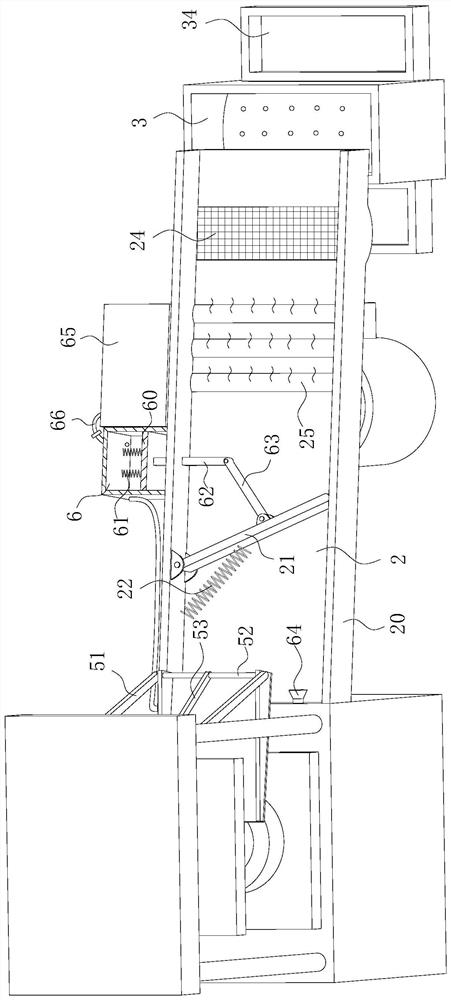

Method used

Image

Examples

Embodiment approach

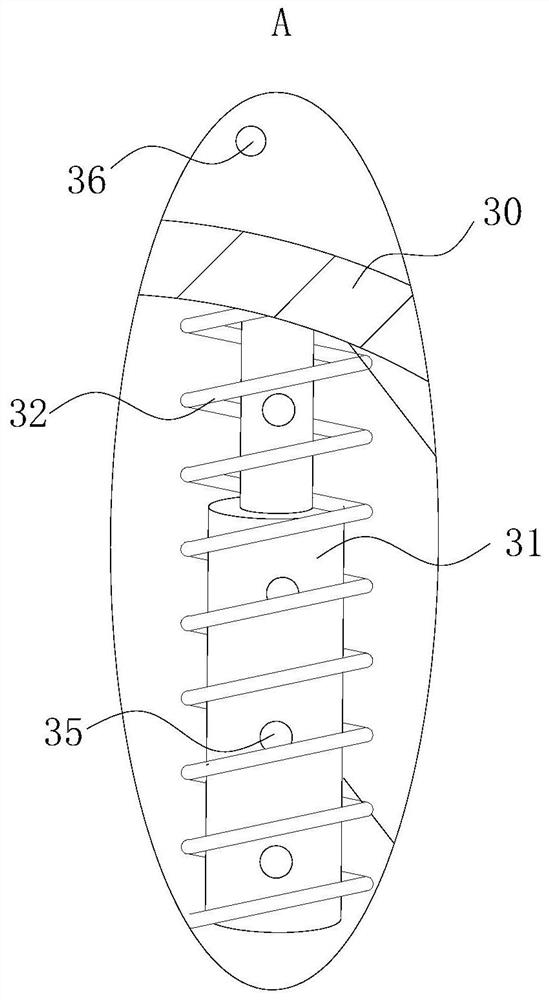

[0028] As an embodiment of the present invention, the first collection box 3 is slidably connected with a slide plate 30 with an arc-shaped cross-section. Arranged telescopic rod 31; the outside of the telescopic rod 31 is equipped with a third spring 32, and the two ends of the third spring 32 are fixedly connected with the lower surface of the slide plate 30 and the bottom inner wall of the first collection box 3; the first The left and right side walls of the collection box 3 are provided with a through groove 33 at the position below the slide plate 30, and the left and right sides of the first collection box 3 are provided with a second collection box 34, and the second collection box 34 is connected to the through groove. 33 one-to-one correspondence settings;

[0029] When working, the workpiece falls from the feeding plate 2 to the upper surface of the slide plate 30. When the workpiece falls, the impact and extrusion slide plate 30 moves downward continuously, so that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com