Coal-fired boiler convenient to improve coal combustion efficiency

A coal-fired boiler and combustion efficiency technology, which is applied in the combustion method, combustion control, and fuel supply regulation, etc., can solve the problems of different sizes and low coal combustion efficiency, and achieve dust prevention, simple structure and fast cutting process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

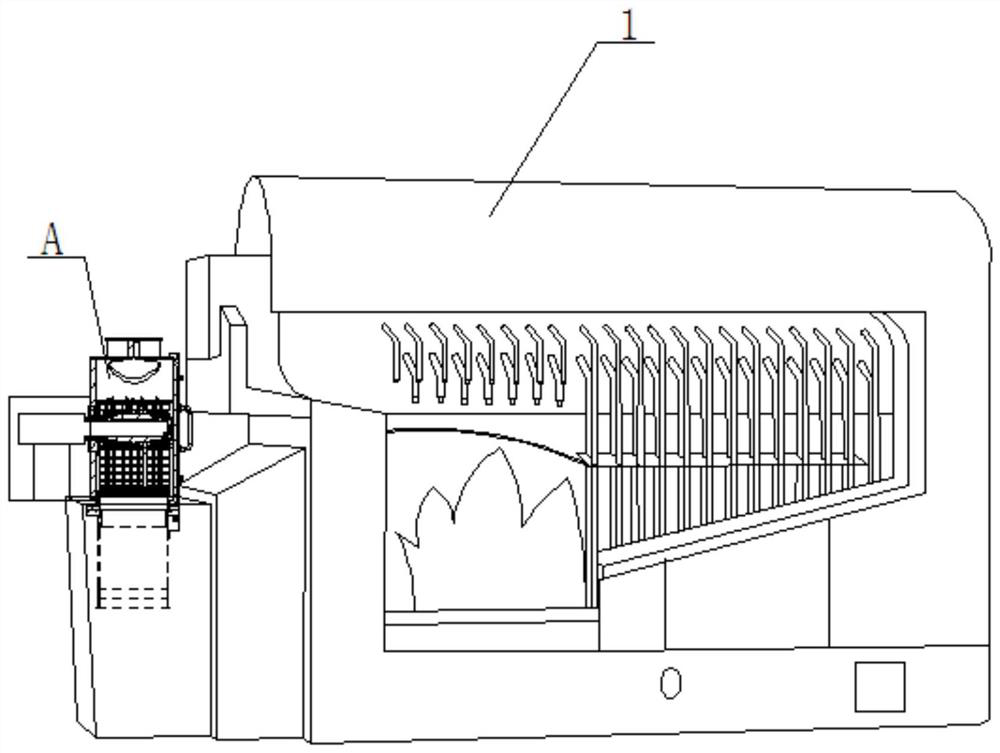

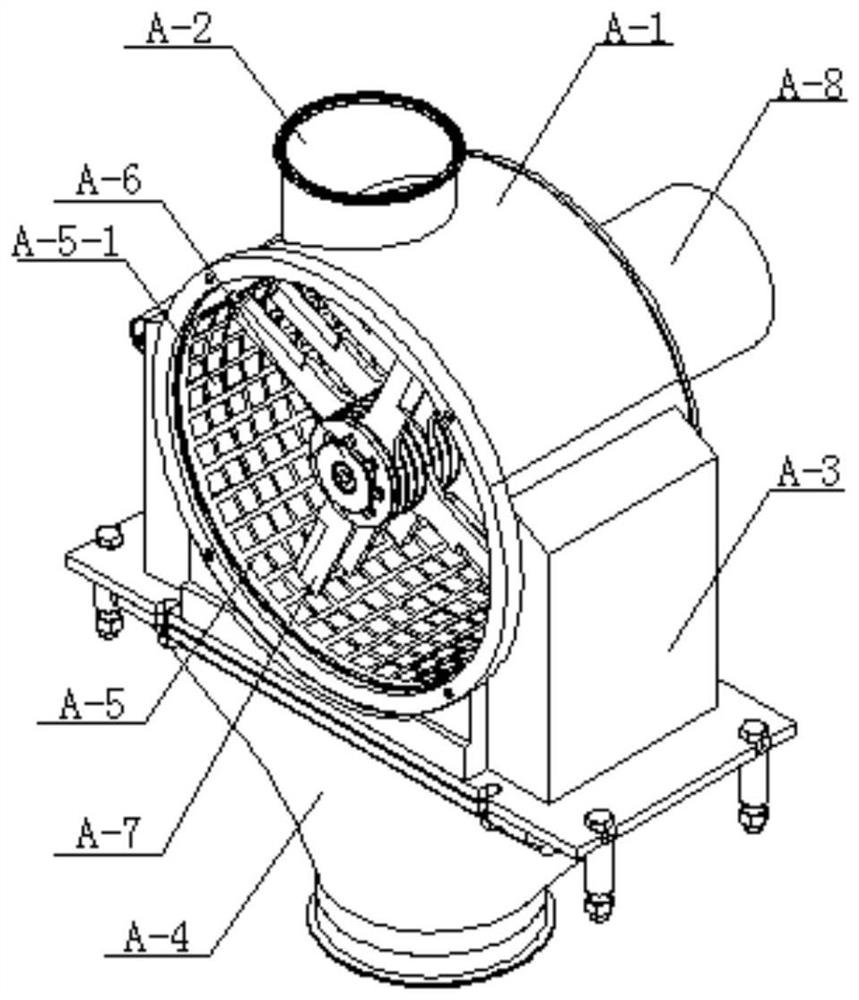

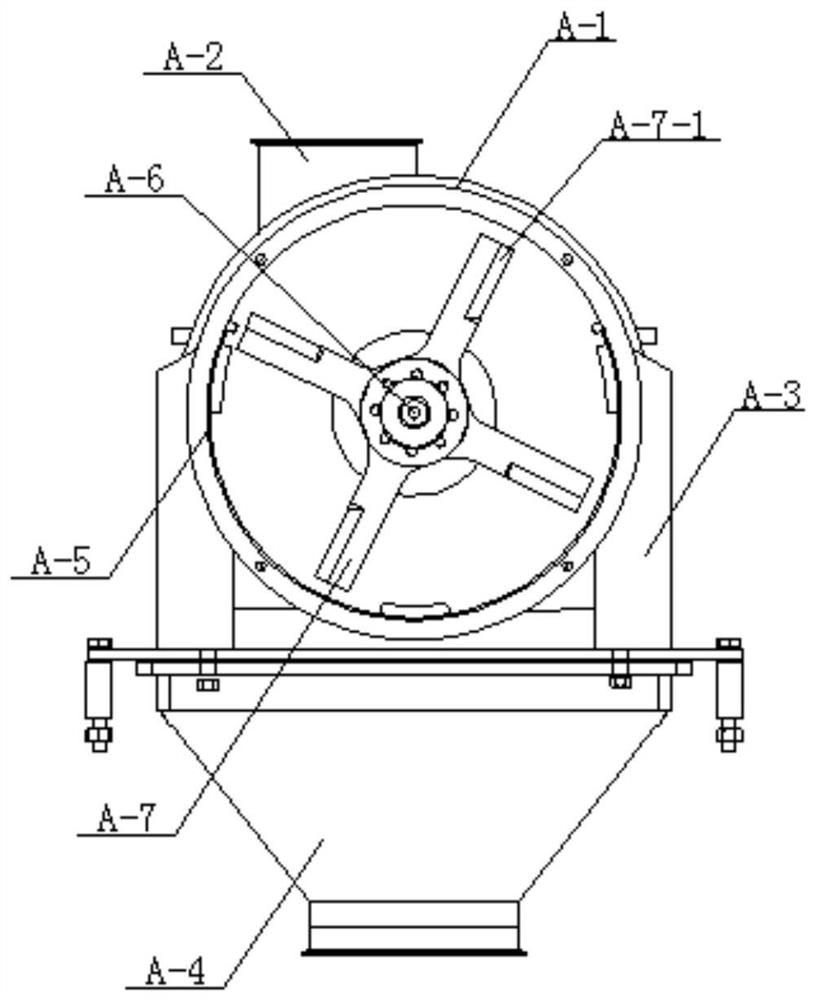

[0021] Specific implementation mode one: combine Figure 1 to Figure 4 Describe this embodiment, a kind of coal-fired boiler that is convenient to improve coal combustion efficiency in this embodiment includes a coal-fired boiler body 1, and it also includes a coal pulverizing device A, and the coal pulverizing device A is installed at the coal inlet of the coal-fired boiler body 1, The coal crushing device A includes a crushing cylinder A-1, a coal inlet pipe A-2, a mounting frame A-3, a coal outlet A-4, a crushing net A-5, a crushing shaft A-6, and a plurality of crushing paddles A -7 and motor A-8, the installation frame A-3 is installed on the coal inlet of the coal-fired boiler body 1, the coal outlet A-4 is installed at the lower end of the installation frame A-3, and the coal outlet A-4 is located at the In the coal inlet of the coal boiler body 1, the crushing cylinder A-1 is installed on the upper end of the installation frame A-3, and the coal inlet pipe A-2 is insta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com