MgAl LDO/nitrogen vacancy carbon nitride-based photocatalyst as well as preparation method and application thereof

A carbon nitride-based, photocatalyst technology, applied in the field of nanomaterials and photocatalysis, can solve the problems of low conversion rate and achieve the effects of short cycle, improved activity and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

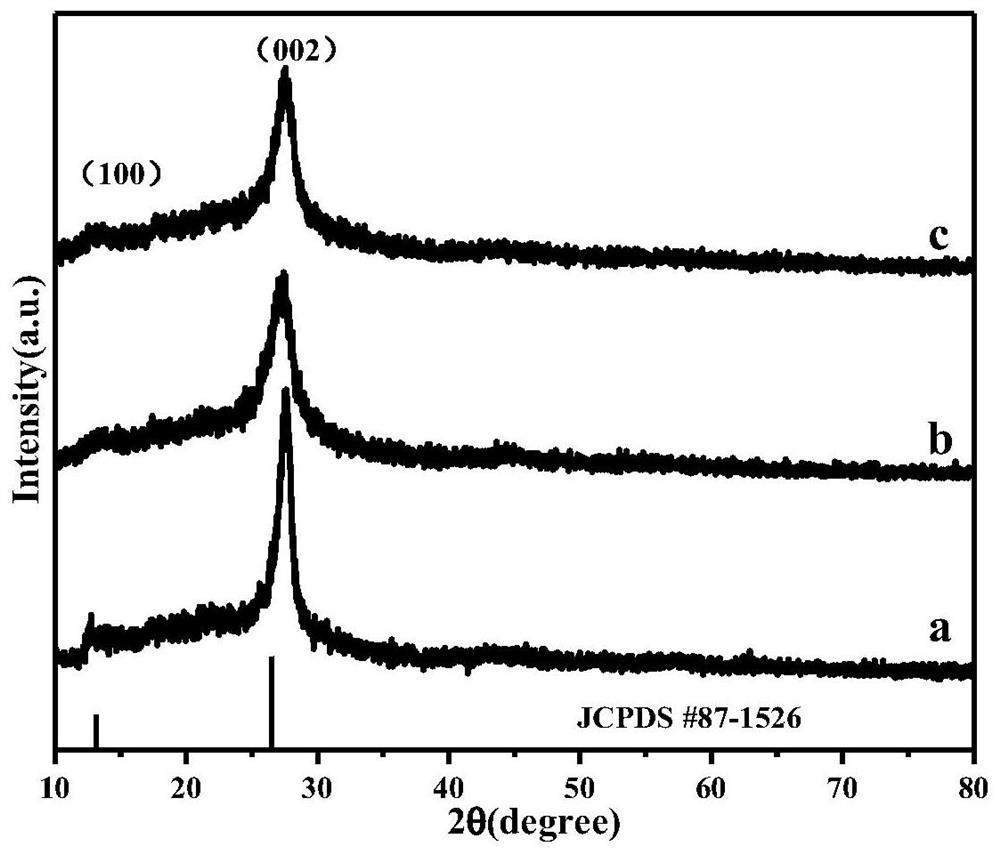

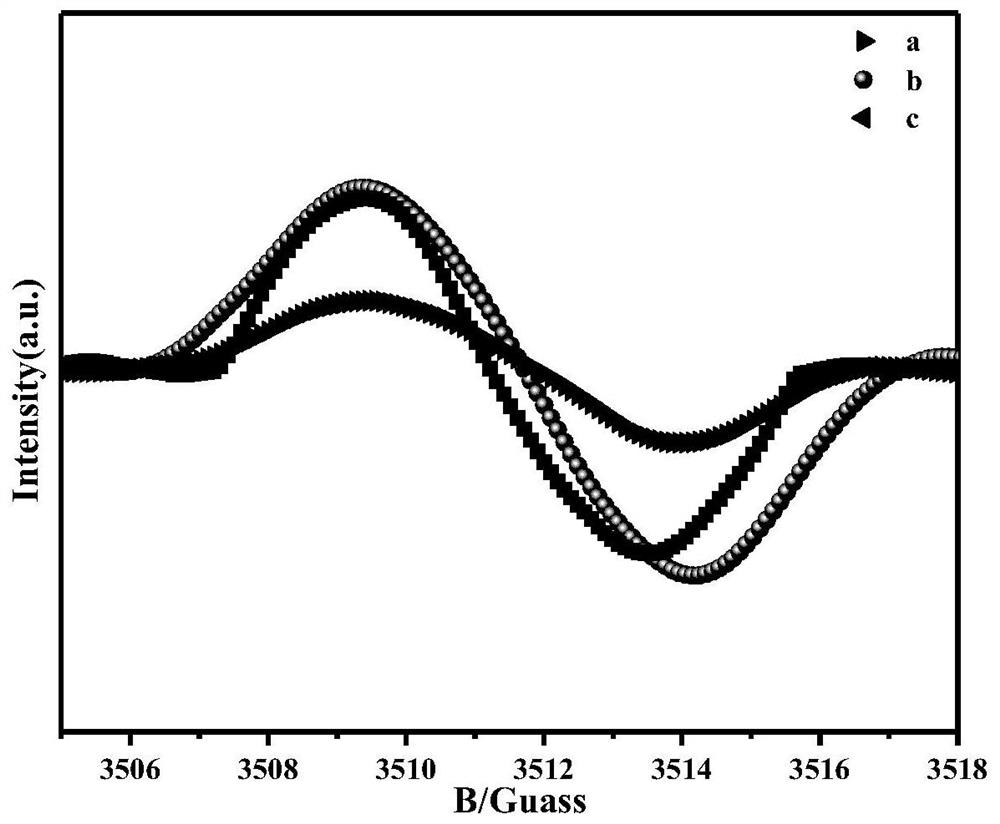

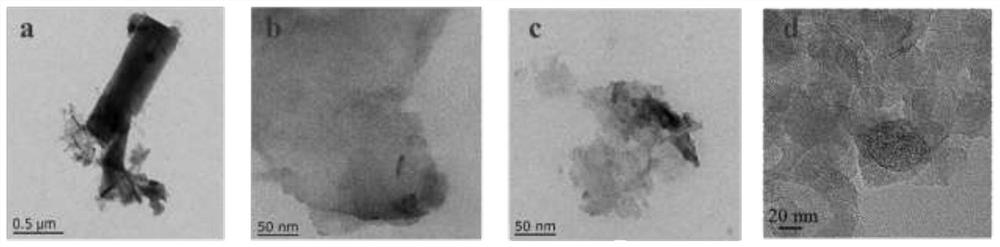

[0038] (1) Preparation of nitrogen vacancy g-C 3 N 4 Nanosheets, spare:

[0039] Weigh 1g of DCDA and 5g of NH 4 Cl, DCDA and NH to be weighed 4 Cl was added to 50mL water in turn and stirred until it was transparent and colorless, then the resulting clear solution was frozen at -4°C for 12h, and then the frozen solution was quickly transferred to a vacuum freeze dryer to freeze-dry to obtain white DCDA and NH 4 Cl mixed crystals, the mixed crystals were placed in a semi-closed crucible, and then the crucible was transferred to an automatic temperature-controlled heating tube furnace in N 2 Calcined at 550°C for 4 hours under air protection, cooled to room temperature naturally, took it out, and ground it into powder with a mortar to obtain nitrogen vacancy g-C 3 N 4 Nanosheets.

[0040] (2) Prepare magnesium-aluminum layered double hydroxide (MgAl LDH) nanosheet material, for subsequent use:

[0041] Weigh 5.769g of Mg(NO 3 ) 2 ·6H 2 O and 2.813g of Al(NO 3 ) 3 9H...

Embodiment 2

[0045] The step (1) of this example is identical with example 1 step (2);

[0046] (2) Preparation of magnesium aluminum double metal oxide (MgAl LDO) nanosheet material: Take 20ml of MgAl LDH suspension, stir and evaporate to dryness at 80°C, then grind the evaporated product into powder in a mortar, and place in Then transfer the alumina porcelain boat to an automatic temperature-controlled tube furnace for calcination at 400 °C for 3 hours, after cooling to room temperature naturally, take it out, and grind it into powder with a mortar to obtain MgAl LDO nanosheet material.

Embodiment 3

[0048] Step (1) and step (2) of this example are identical with step (1) and step (2) of example 1;

[0049] (3) Preparation of MgAl LDH / N v -CN nanosheet composite photocatalytic material: the g-C of nitrogen vacancies obtained in step (1) 3 N 4 Disperse the nanosheets in 10ml of deionized water, stir and ultrasonically disperse to obtain a uniform and stable yellow suspension, add the MgAl LDH solution obtained in step (2) dropwise while stirring, and dissolve the mixed solution at 80°C after the dropwise addition Stir and evaporate to dryness.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com