Oxygenator, oxygenator hollow fiber membrane woven assembly and forming method of oxygenator hollow fiber membrane woven assembly

A molding method and fiber membrane technology, applied in the field of oxygenator, can solve the problems of low design requirements, unsmooth blood flow, easy formation of dead ends, etc., and achieve the effects of good diversion, shortening the blood flow path, and increasing the contact area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

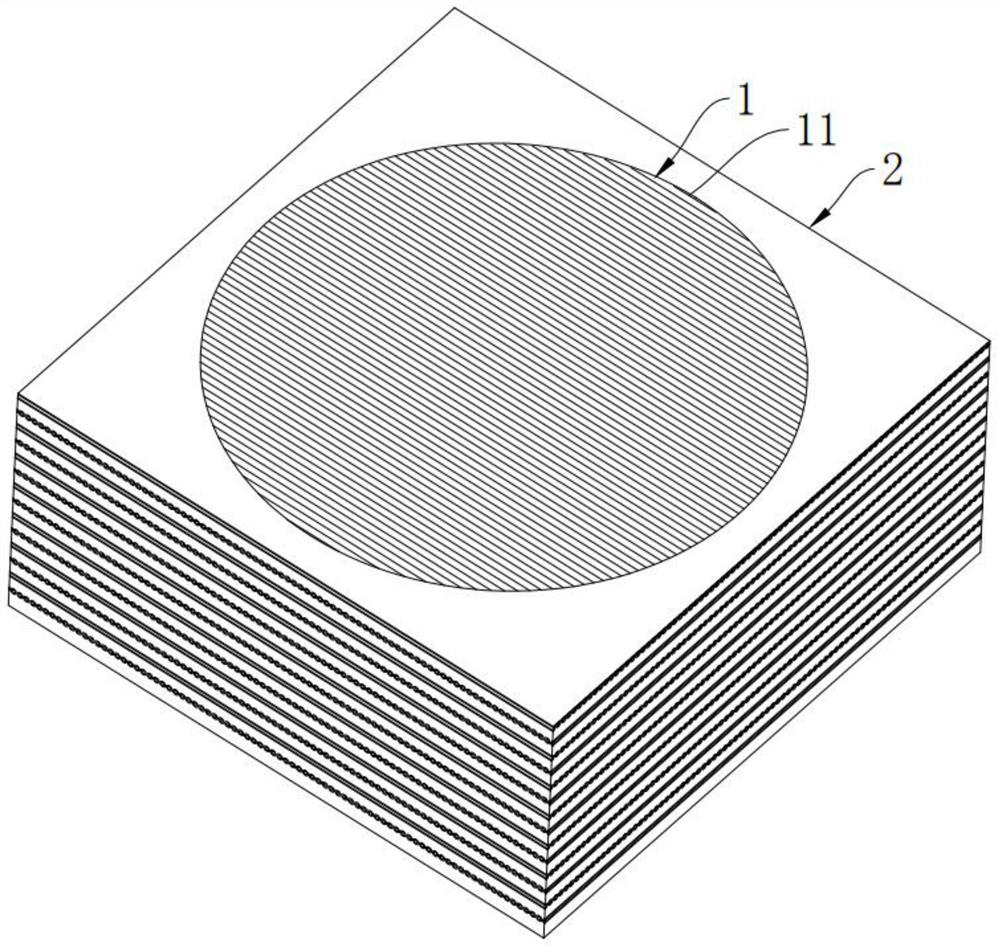

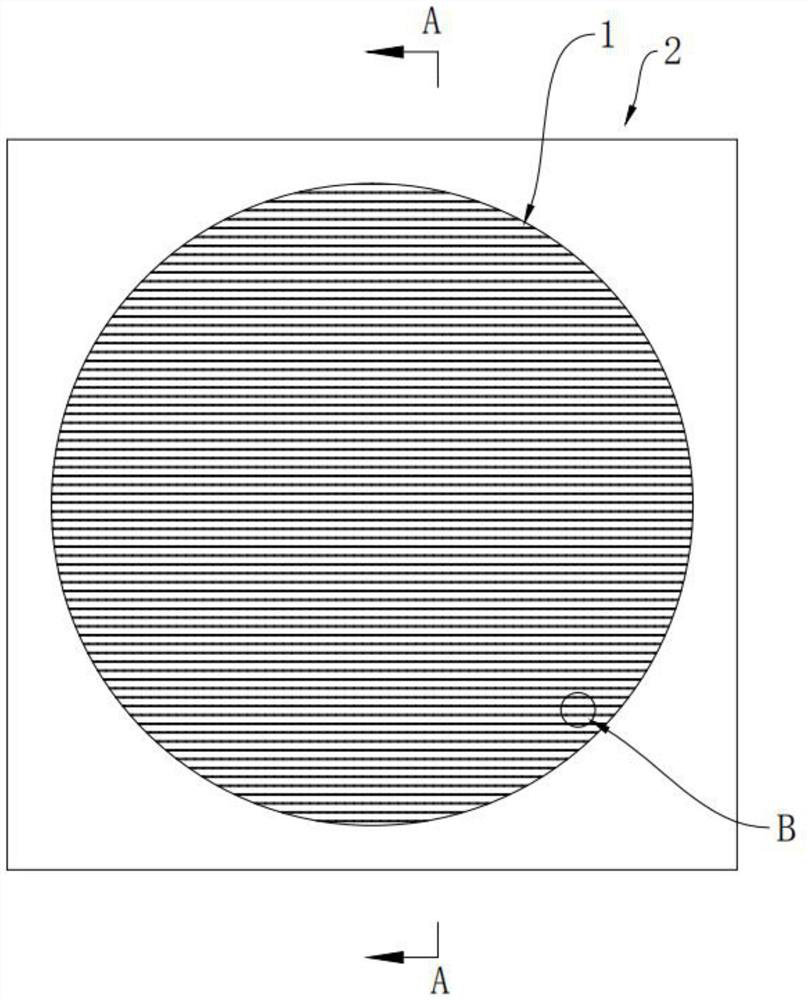

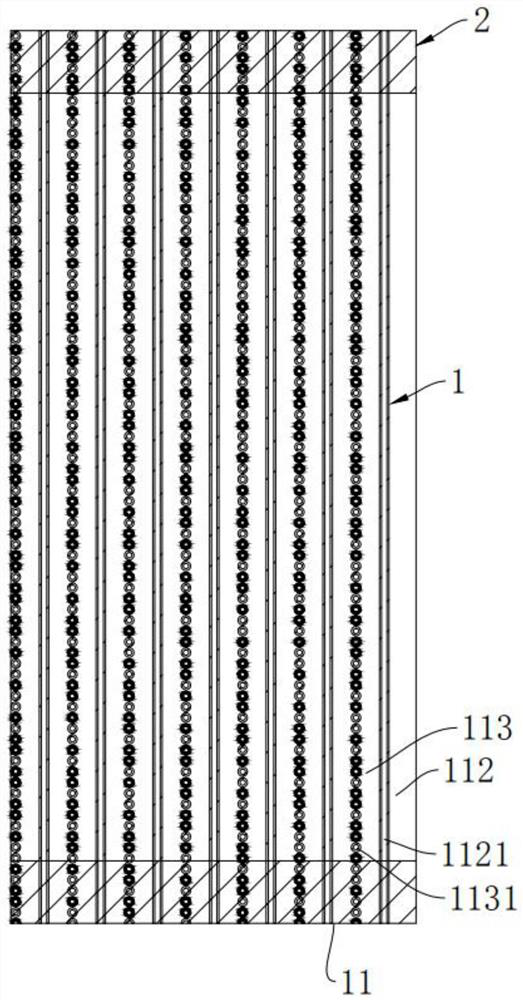

[0045] refer to Figure 1 to Figure 4 , figure 1 It is a schematic structural view of the hollow fiber membrane braided assembly of the oxygenator of the embodiment, figure 2 It is a structural schematic diagram of another perspective of the hollow fiber membrane braided assembly of the oxygenator of the embodiment, image 3 For example figure 2 Sectional view of A-A plane, Figure 4 It is a schematic diagram of the structure of the hollow fiber membrane part of the embodiment. The braided hollow fiber membrane assembly of the oxygenator in this embodiment includes a hollow fiber membrane part 1 and a sealing part 2 . The hollow fiber membrane part 1 includes a plurality of hollow fiber units 11, and the plurality of hollow fiber units 11 are stacked in sequence; the sealing part 2 is sealed on the outer edge of the stacked hollow fiber units 11; the cross section of the inner ring of the sealing part 2 It is elliptical, so that a plurality of hollow fiber units 11 arra...

Embodiment 2

[0059] refer to Figure 7 , Figure 7 It is a flow chart of the forming method of the hollow fiber membrane braided module of the oxygenator in the embodiment. The method for forming the braided hollow fiber membrane assembly of the oxygenator in this embodiment includes the following steps:

[0060] S1, weaving a plurality of hollow fiber units 11 in sequence, and making the plurality of hollow fiber units 11 stacked in sequence.

[0061] S2, centrifugally pouring glue on the outer edges of multiple hollow fiber units 11 stacked to form the sealing part 2; Cooperate to form a blood flow channel with an elliptical or circular cross section.

[0062] S3, cutting the outer edge of the sealing portion 2 to leak out the hollow fiber unit 11 .

[0063] By sequentially weaving a plurality of hollow fiber units 11, the plurality of hollow fiber units 11 are sequentially stacked, and then the outer edges of the stacked hollow fiber units 11 are centrifugally filled with glue to fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com