Direct current charging connection device and method applied to automatic charging

A technology of direct current charging and automatic charging, which is applied in the parts of connecting devices, electric vehicle charging technology, connection, etc., and can solve the problems of immature visual positioning technology, difficult marketing, and high price of the whole machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

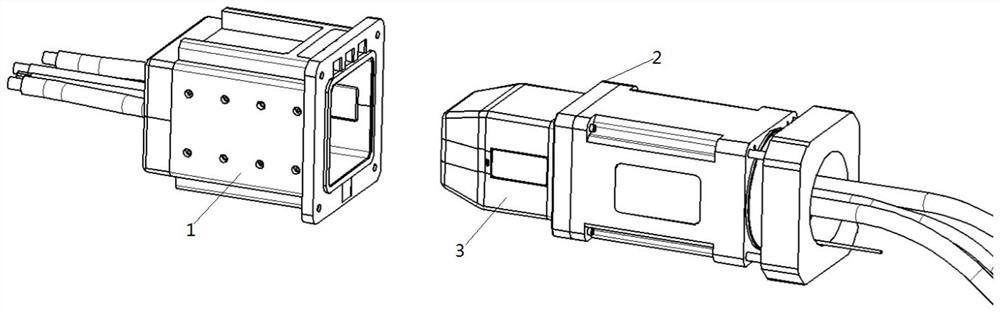

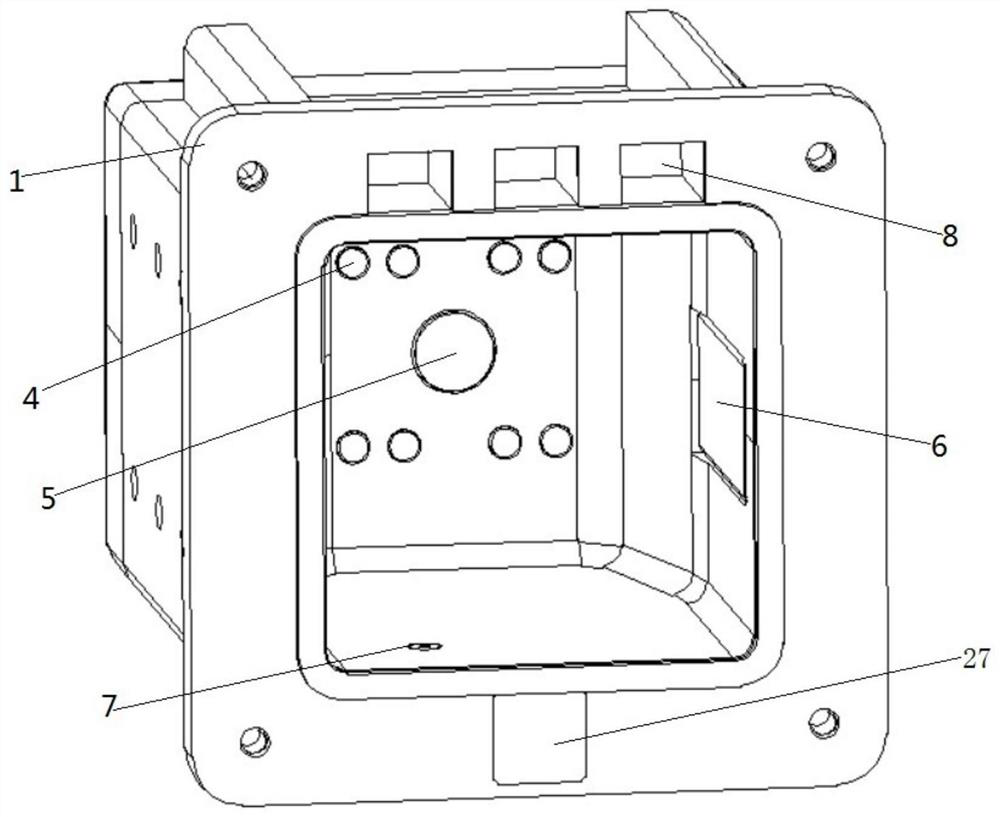

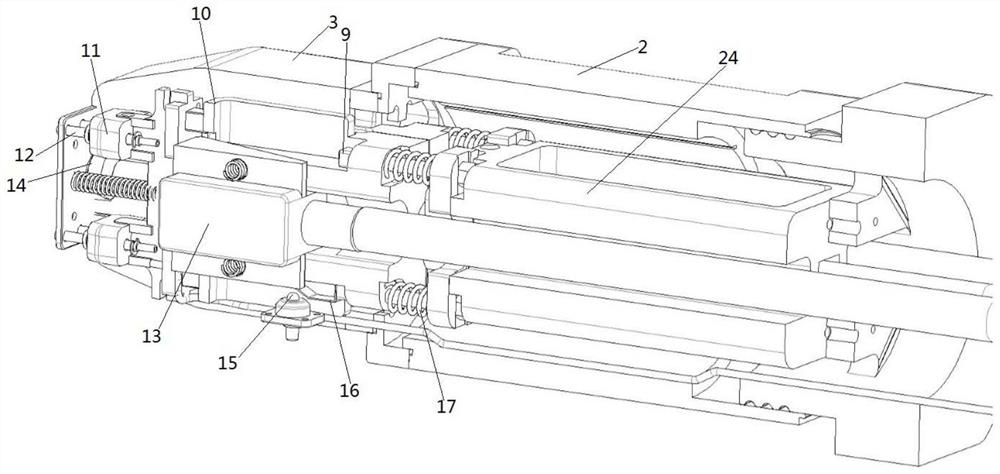

[0040] Such as figure 1 As shown, the present invention provides a DC charging connection device used in automatic charging, including a gun base conductive device and a gun tip conductive device, wherein, such as figure 2 As shown, the conductive device of the gun holder includes a gun holder housing 1 with an open end, an identification feature 8 is provided on the opening end surface of the gun holder housing 1, and a PE electrode mother part 5 is provided on the inner cavity wall of the gun holder housing 1 And the electrode protruding female part, preferably, the electrode protruding female part includes the signal electrode female part 4, the power electrode female part 6 and the CC1 electrode female part 7, wherein the PE electrode female part 5 and the signal electrode female part 4 are arranged on the gun seat In the same plane in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com