Negative electrode material, preparation method thereof and lithium ion battery

A technology of negative electrode materials and carbon materials, applied in the field of negative electrode materials and their preparation, and lithium-ion batteries, can solve problems such as limited specific capacity effect, achieve the effect of maintaining integrity and improving diffusion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

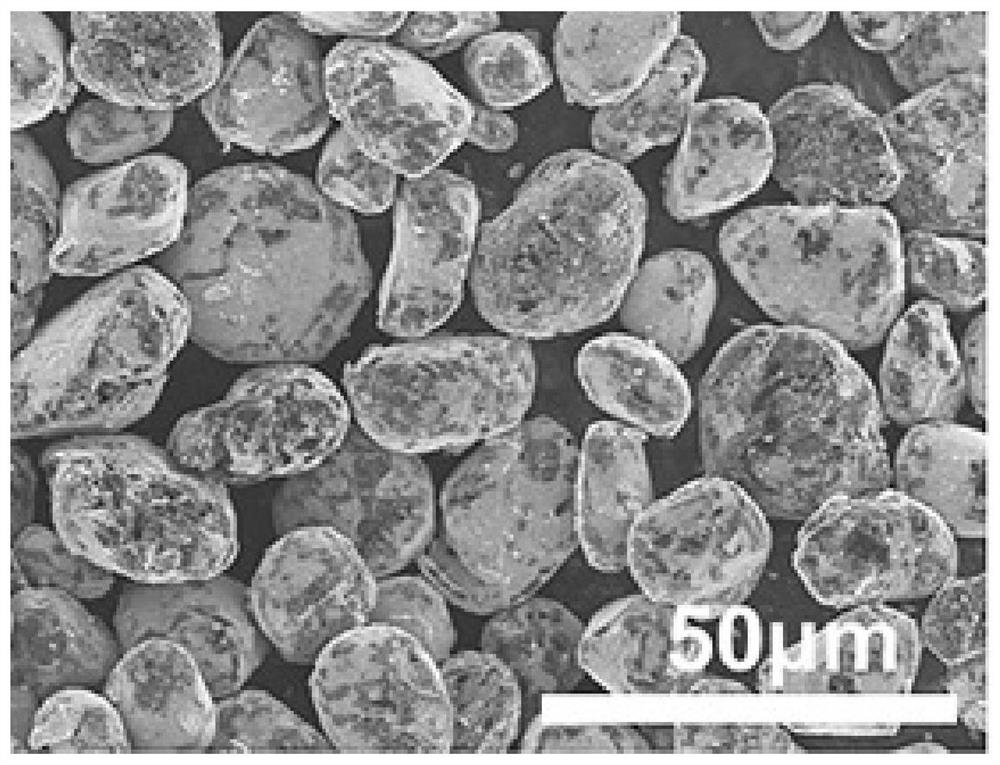

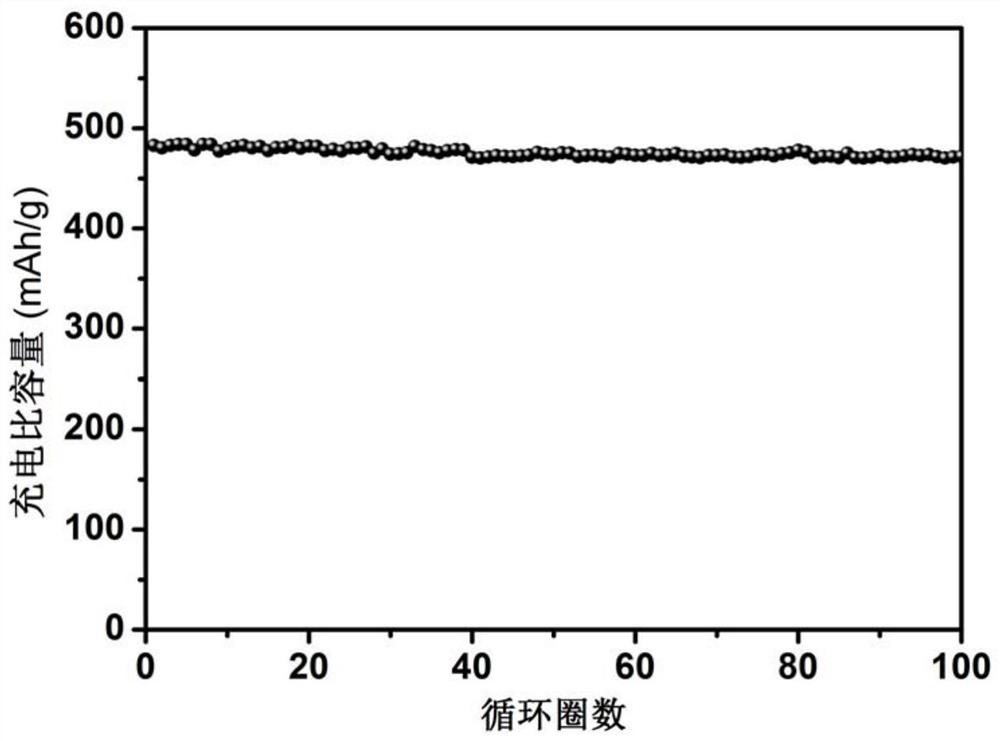

Image

Examples

Embodiment 1

[0075] The present embodiment prepares the negative electrode material according to the following method:

[0076] Weigh 300mg of trishydroxymethylaminomethane into 100mL deionized water, then add dilute hydrochloric acid with a concentration of 0.1mol / L, stir for 20min, adjust the pH value to 8.5, and then immerse 1000mg of natural graphite in the trihydroxymethylaminomethane Add 500mg of dopamine hydrochloride to the aqueous solution of methylaminomethane, and stir at 60°C for 12h to obtain polydopamine-coated natural graphite; add 1000mg of the polydopamine-coated natural graphite obtained above to 100ml deionized water and 10ml alcohol mixed solution, ultrasonically dispersed for 20min, then added 400mg of ZnCl 2 and 300mg of (NH 4 ) 2 C 2 o 4 , stirred for 45min, and then the precipitate was placed in a tube furnace, carbonized at 800°C for 12h, and nitrogen was fed at a constant speed throughout the carbonization process to obtain the negative electrode material (a Z...

Embodiment 2

[0082] The present embodiment prepares the negative electrode material according to the following method:

[0083]Weigh 300mg of trishydroxymethylaminomethane and add it into 100mL deionized water, then add dilute hydrochloric acid with a concentration of 0.1mol / L, stir for 20min, adjust the pH value to 8.5, and then immerse 1000mg of natural graphite in trimethylol In the aqueous solution of aminomethane, add 300mg of dopamine hydrochloride subsequently, stir at 60 ℃ for 12h, obtain polydopamine-coated natural graphite; 1000mg above-mentioned obtained polydopamine-coated natural graphite is added to 100ml deionized water and In the mixed solution of 10ml alcohol, ultrasonically disperse for 20min, then add 400mg of ZnCl 2 and 300mg of (NH 4 ) 2 C 2 o 4 , stirred for 45min, and then the precipitate was placed in a tube furnace, carbonized at 800°C for 12h, and nitrogen was fed at a constant speed throughout the carbonization process to obtain the negative electrode materia...

Embodiment 3

[0087] The present embodiment prepares the negative electrode material according to the following method:

[0088] Weigh 300mg of trishydroxymethylaminomethane and add it into 100mL deionized water, then add dilute hydrochloric acid with a concentration of 0.1mol / L, stir for 20min, adjust the pH value to 8.5, and then immerse 1000mg of natural graphite in trimethylol In the aqueous solution of aminomethane, add 700mg of dopamine hydrochloride subsequently, stir at 60 ℃ for 12h, obtain polydopamine-coated natural graphite; 1000mg above-mentioned obtained polydopamine-coated natural graphite is added to 100ml deionized water and In the mixed solution of 10ml alcohol, ultrasonically disperse for 20min, then add 400mg of ZnCl 2 and 300mg of (NH 4 ) 2 C 2 o 4 , stirred for 45min, and then the precipitate was placed in a tube furnace, carbonized at 800°C for 12h, and nitrogen was fed at a constant speed throughout the carbonization process to obtain the negative electrode materi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Median particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com