MES-based production management system

A technology of production management system and product information, applied in the field of MES-based production management system, can solve the problems of affecting production efficiency, large scanning base, high probability of scanning recognition, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

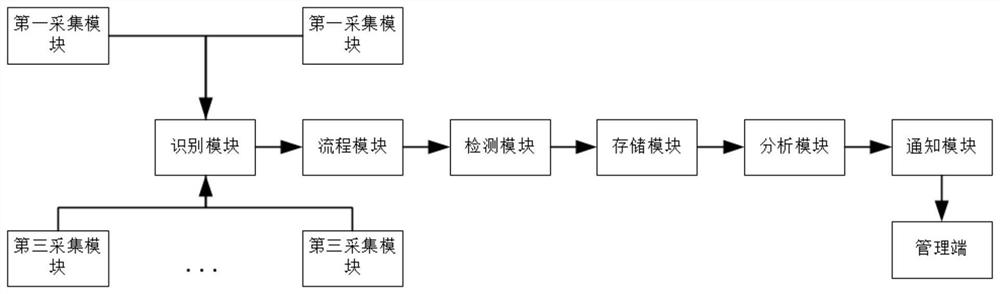

[0041] Such as figure 1 As shown, an MES-based production management system in this embodiment includes a loading mechanism, a carrier, a first acquisition module, a second acquisition module, a third acquisition module, an identification module, a process module, a detection module, a storage module, Analysis module, notification module and management terminal.

[0042] The loading mechanism is used to load the camera module onto the vehicle. In this embodiment, the loading mechanism uses a robotic arm to grab the camera and load it onto the carrier.

[0043] The carrier is used to carry the camera module for processing and testing; the carrier is provided with a two-dimensional code. In other words, the carrier is moved in the subsequent processing and testing processes, so that the camera module moves together with the carrier.

[0044] The first collection module is used to collect the QR code on the camera module after the camera module is loaded on the carrier, identi...

Embodiment 2

[0057] The difference between this embodiment and Embodiment 1 is that when the first acquisition module collects the QR code on the camera module in this embodiment, it first takes a picture of the camera module, and then extracts the QR code from the photo of the camera module ;

[0058] When the second collection module collects the two-dimensional code on the vehicle, it first takes pictures of the vehicle, and then extracts the two-dimensional code from the photo of the vehicle;

[0059] The first standard image and the second standard image are also pre-stored in the storage module. In this embodiment, the first standard image is a photo taken by the first acquisition module to the camera module when the relative position of the vehicle and the camera module meets the requirements; the second standard image is when the relative position of the vehicle and the camera module meets the requirements , the photos taken by the second acquisition module on the vehicle.

[006...

Embodiment 3

[0064] The difference between this implementation and Embodiment 1 is that in this embodiment, a vibration sensor, an acceleration sensor, and a gyroscope are installed on the carrier, which are used to collect vibration data, acceleration data, and deflection angle data respectively.

[0065] A mounting slot is opened on the carrier, and a verification device is arranged in the mounting slot.

[0066] The verification device includes a moving block made of insulating material, and the cross-sectional area of the moving block is smaller than that of the installation groove.

[0067] Two first metal contacts are fixed on the lower surface of the moving block, and the two first metal contacts are connected by wires inside the bonding block; two permanent magnets with opposite magnetic poles are also fixed on the lower surface of the insulating block;

[0068] The verification device also includes a power supply, a control circuit board, two second metal contacts and two electr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com