Pressure sensing device based on circular dichroism

A sensing device and circular dichroism technology, applied in the field of pressure sensing devices based on circular dichroism, can solve the problems of inaccurate data results and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

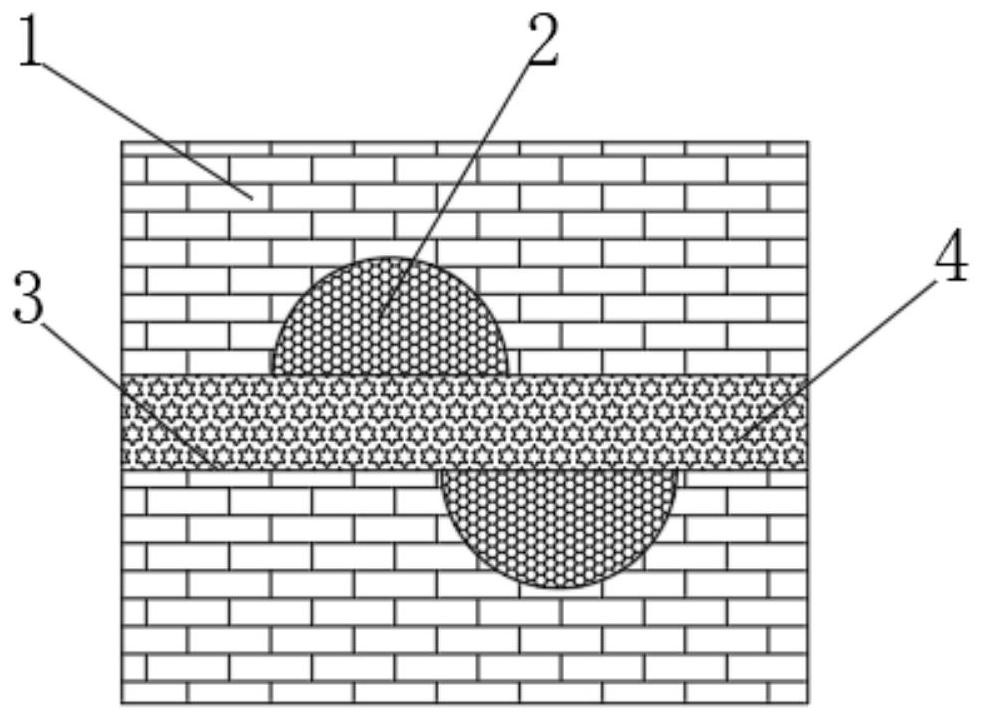

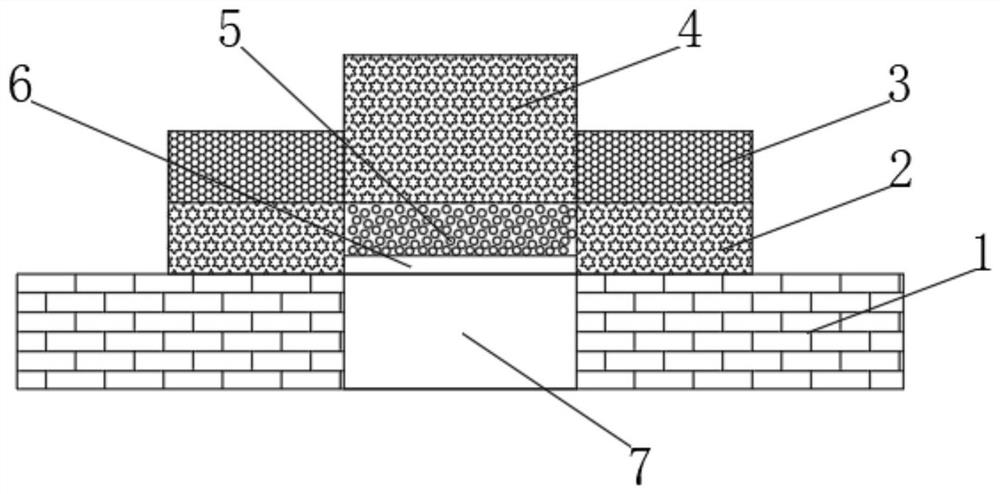

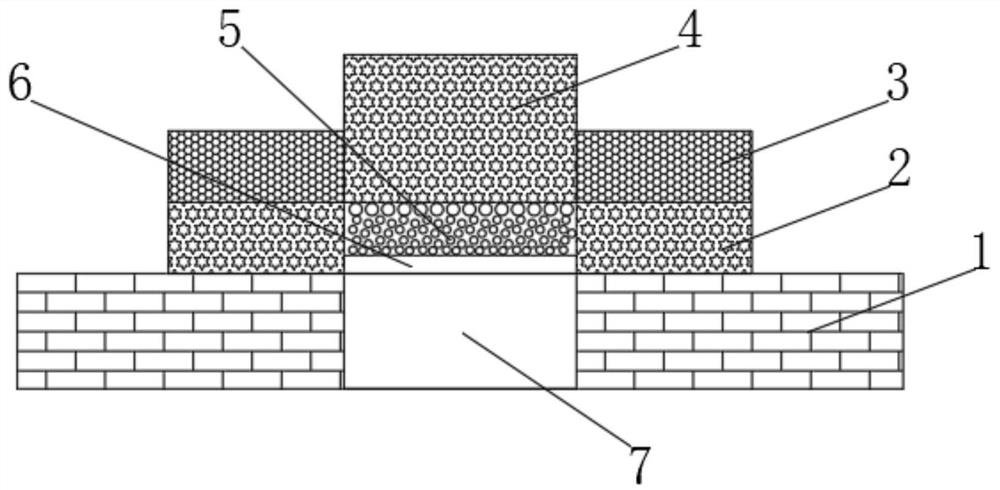

[0021] see figure 1 , figure 2 , a pressure sensing device based on circular dichroism, including a metal film 1 with gaps, flexible material 1 2, metal block 3, flexible material 2 4, metal particles 5, flexible material 6 with holes and a rectangular cavity 7. A flexible material 1 is provided on the metal film 1 with a gap, a metal block 3 is provided on the flexible material 2, a rectangular cavity 7 is opened in the metal film 1 with a gap, and a hole with a hole is provided in the flexible material 1 . The flexible material 6 is provided with metal particles 5 on the flexible material 6 with holes. The flexible material 2 is made of polydimethylsiloxane. Two metal blocks 3 are dislocated on the flexible material 2. The two metal blocks 3 are symmetrically distributed on both sides of the rectangular cavity 7, and the hole ratio of the flexible material 6 with holes is smaller than the size of the metal particles 5.

[0022] Specifically, a penetrating rectangular groo...

Embodiment 2

[0024] see figure 1 , figure 2 , a pressure sensing device based on circular dichroism, including a metal film 1 with gaps, flexible material 1 2, metal block 3, flexible material 2 4, metal particles 5, flexible material 6 with holes and a rectangular cavity 7. A flexible material 1 is provided on the metal film 1 with a gap, a metal block 3 is provided on the flexible material 2, a rectangular cavity 7 is opened in the metal film 1 with a gap, and a hole with a hole is provided in the flexible material 1 . The flexible material 6 is provided with metal particles 5 on the flexible material 6 with holes. The flexible material 2 is made of polydimethylsiloxane. Two metal blocks 3 are dislocated on the flexible material 2. The two metal blocks 3 are symmetrically distributed on both sides of the rectangular cavity 7, and the hole ratio of the flexible material 6 with holes is smaller than the size of the metal particles 5.

[0025] Specifically, a penetrating rectangular groo...

Embodiment 3

[0028] see figure 1 , figure 2 , a pressure sensing device based on circular dichroism, including a metal film 1 with gaps, flexible material 1 2, metal block 3, flexible material 2 4, metal particles 5, flexible material 6 with holes and a rectangular cavity 7. A flexible material 1 is provided on the metal film 1 with a gap, a metal block 3 is provided on the flexible material 2, a rectangular cavity 7 is opened in the metal film 1 with a gap, and a hole with a hole is provided in the flexible material 1 . The flexible material 6 is provided with metal particles 5 on the flexible material 6 with holes. The flexible material 2 is made of polydimethylsiloxane. Two metal blocks 3 are dislocated on the flexible material 2. The two metal blocks 3 are symmetrically distributed on both sides of the rectangular cavity 7, and the hole ratio of the flexible material 6 with holes is smaller than the size of the metal particles 5.

[0029] Specifically, there is a through rectangular...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com