Lock catch steel pipe pile cofferdam applied under condition of water level change and construction method

A technology of locking steel pipe and changing water level, applied in excavation, sheet pile wall, infrastructure engineering, etc., can solve the problem that the steel pipe pile cofferdam cannot be directly applied, and reduce the purchase cost, turnover cost, and processing cycle. The effect of short and saving construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

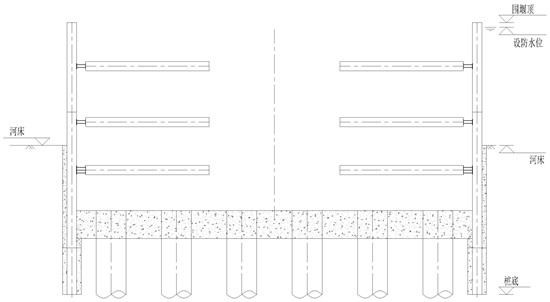

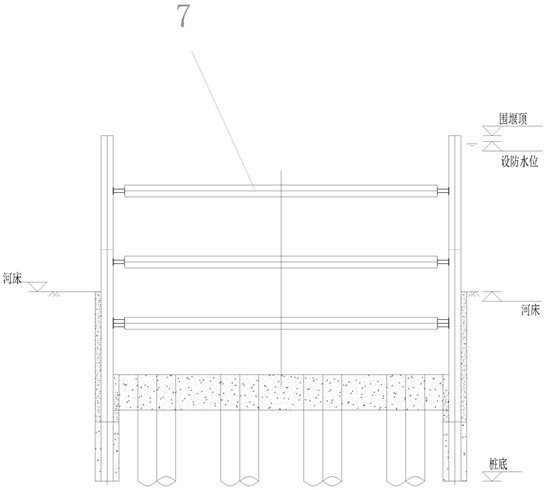

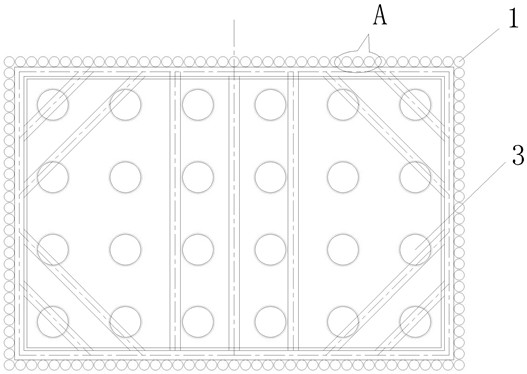

[0031] The specific implementation manner of the present invention will be described below with reference to the accompanying drawings. Such as Figures 1 to 6 Shown: a locking steel pipe pile cofferdam applied to the condition of water level changes, which is surrounded by multiple first-section steel pipe piles 1, and the adjacent first-section steel pipe piles 1 are connected to each other through locks 2 connection, the top of the first steel pipe pile 1 is connected to the second steel pipe pile 4, and the adjacent second steel pipe piles 4 are also connected to each other through the lock 2, and the first steel pipe pile 1 The grouting gravel part 11 is filled in the gap between the bottom of the bottom and the guide hole, and the grouting gravel part 11 is formed by crushed stone and solidified cement slurry, and the grouting gravel part 11 is also filled with yellow The mud part 12, that is, first fill the gap between the bottom of the first steel pipe pile 1 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com