Safe, energy-saving and efficient high-temperature chlorine dioxide sanitary towel bleaching equipment

A chlorine dioxide and sanitary napkin technology, applied in the field of bleaching equipment for sanitary napkins, can solve the problems of slow feeding speed of non-woven fabrics, slowing down of bleaching and sterilizing efficiency of non-woven fabrics, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] as attached figure 1 to attach Figure 5 Shown:

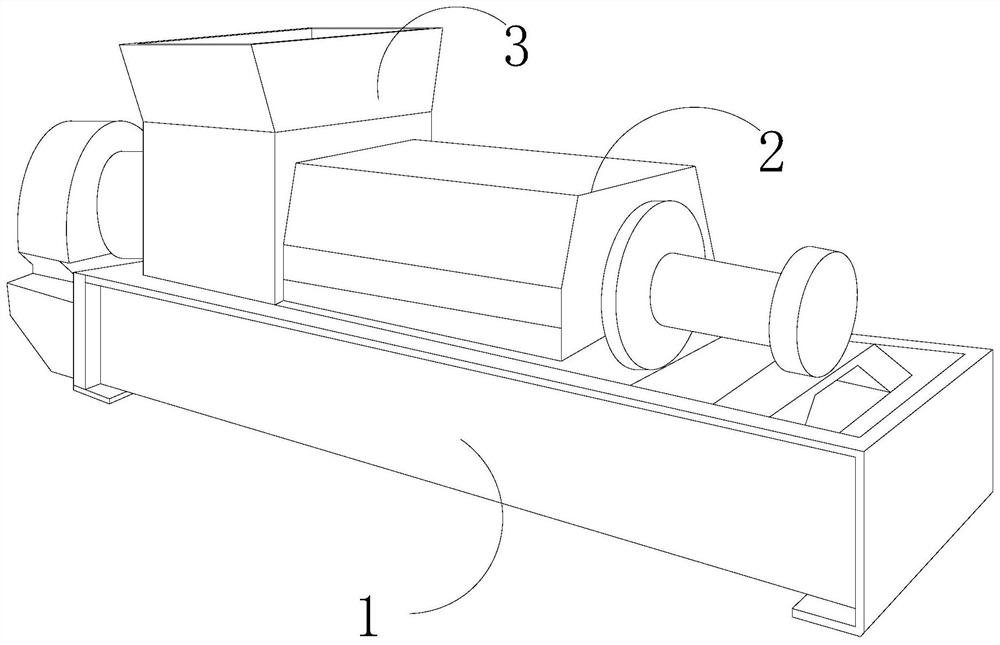

[0028] The invention provides a safe, energy-saving and high-efficiency high-temperature chlorine dioxide sanitary napkin bleaching equipment, the structure of which includes a cleaning pool 1, a screw rod 2, and a feeding hopper 3, the screw rod 2 is horizontally welded on the top of the cleaning pool 1, and the feeding The hopper 3 is vertically welded on the top of the cleaning pool 1 .

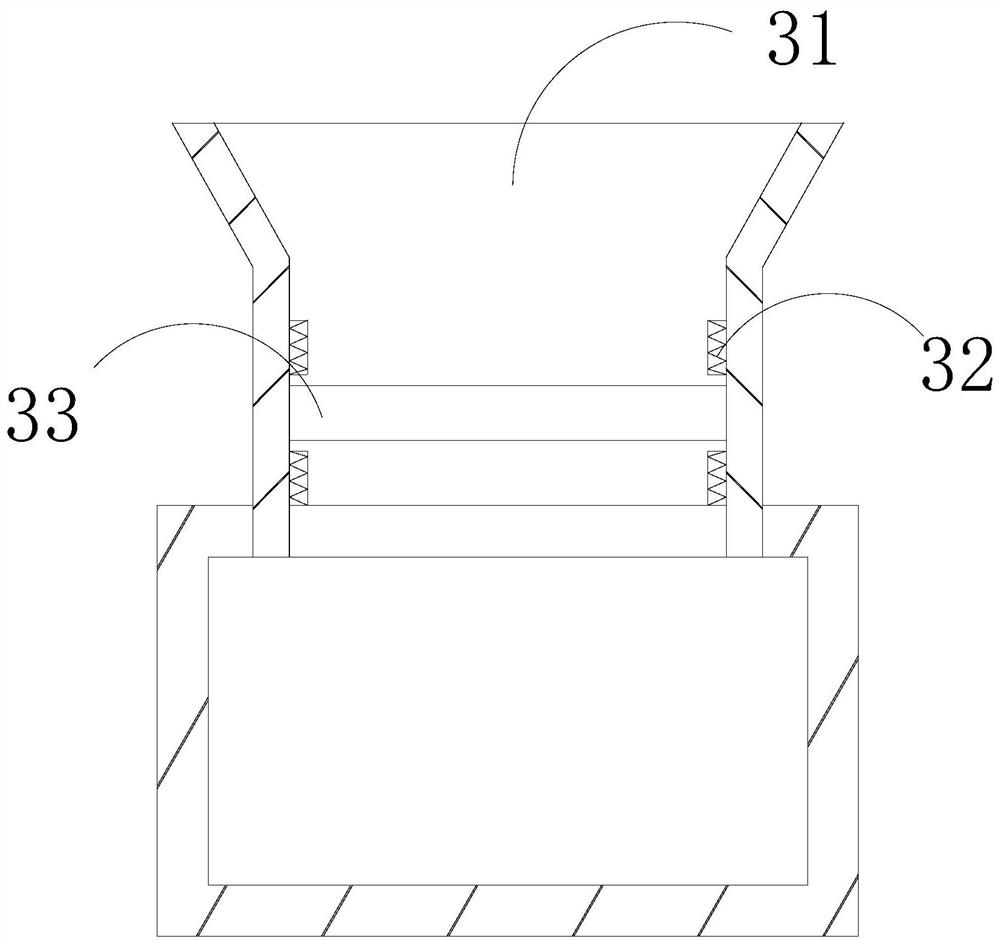

[0029] The feed hopper 3 is provided with a feed port 31, a vibration block 32, and an extruding mechanism 33. The feed port 31 is located inside the feed hopper 3 and communicates with the cleaning pool 1. The vibration block 32 is fixed on The middle and lower part of the inner wall of the feed hopper 3 , the extruding mechanism 33 is located between the vibrating blocks 32 .

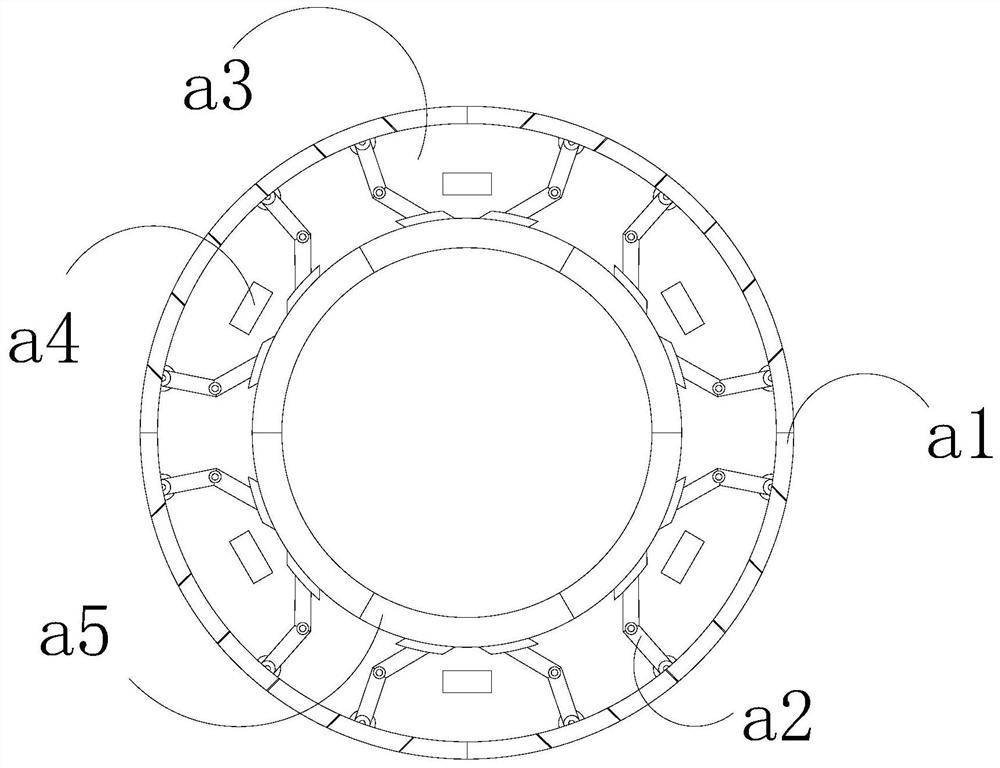

[0030] Wherein, the extruding mechanism 33 is provided with a supporting ring a1, a telescopic rod a2, a slot a3, a push block a4, and an extruding plate...

Embodiment 2

[0036] as attached Figure 6 to attach Figure 8 Shown:

[0037] Wherein, the contact ring d6 is provided with a ring body n1, an elastic block n2, and a clearing block n3, the ring body n1 is located above the contact ring d6, and the clearing block n3 is fixed on the lower surface of the ring body n1 through the elastic block n2, so There are five clearing blocks n3, which evenly cooperate with the rotating block d4, and the clearing block n3 is subjected to the thrust vibration of the elastic block n2, so as to accelerate the rotation speed of the clearing block n3 to push the rotating block d4.

[0038]Wherein, the cleaning block n3 is provided with a fixed strip r1, a telescopic strip r2, a scraper r3, and an air chamber r4, the fixed strip r1 is above the cleaning block n3, and the scraper r3 is installed on the fixed strip r1 through the telescopic strip r2 Below, the air cavity r4 is located between the scraper r3 and the fixed strip r1, and the telescopic strip r2 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com