Carbon fiber C-ring tracheal stent and preparation method thereof

A tracheal stent and carbon fiber prefabricated technology, applied in the field of C-ring tracheal stent and artificial tracheal stent, can solve the problems of small friction coefficient and high surface hardness, and achieve the effect of small friction coefficient, excellent mechanical properties, and biological fixation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

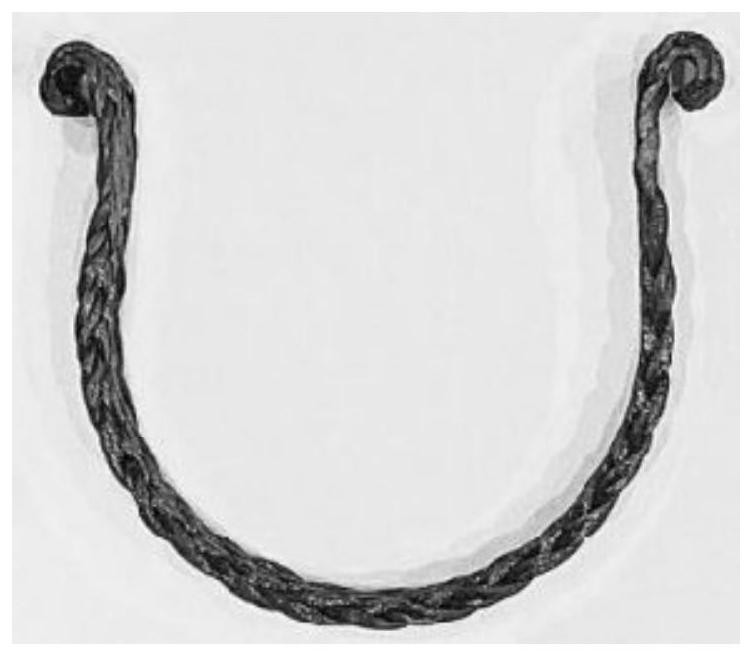

Image

Examples

Embodiment 1

[0052] The preparation method of carbon fiber C-ring tracheal stent comprises the following specific steps:

[0053] 1) Twist the carbon fiber bundles into carbon fiber ropes, select 3 bundles of 1.5k carbon fibers and twist them into ropes, and the diameter of the carbon fiber ropes is 0.1mm; among them, the carbon fiber bundles are not treated with resin removal, and the epoxy resin on the surface accounts for 10% of the carbon fiber mass. 0.8%.

[0054] 2) Weave 12 carbon fiber ropes into carbon fiber braided strips with a width of 8mm and a thickness of 0.8mm.

[0055] 3) The carbon fiber braided strip is heated, baked and shaped with the aid of the mold. During the baking process, the carbon fiber braided strip is vertically applied pressure along the plane, and a steel needle (a steel needle with a tapered head) is inserted into the surface of the carbon fiber braided strip to set a preset value. Leave holes to obtain the carbon fiber strip prefabricated body; the reser...

Embodiment 2

[0062] The preparation method of carbon fiber C-ring tracheal stent comprises the following concrete steps:

[0063] 1) Twist the carbon fiber bundles into carbon fiber ropes, select 3 bundles of 1.5k carbon fibers and twist them into ropes, and the diameter of the carbon fiber ropes is 0.1mm; among them, the carbon fiber bundles are not treated with resin removal, and the epoxy resin on the surface accounts for 10% of the carbon fiber mass. 0.8%.

[0064] 2) Weave 12 carbon fiber ropes into carbon fiber braided strips with a width of 8mm and a thickness of 0.8mm.

[0065] 3) The carbon fiber braided strip is heated, baked and shaped with the help of a mold, and a tensile force is applied to the carbon fiber braided strip in the axial direction during the baking process, and a steel needle (a steel needle with a tapered head) is inserted into the surface of the carbon fiber braided strip to set a preset value. Leave holes to obtain the prefabricated carbon fiber strip; the re...

Embodiment 3

[0072] The preparation method of carbon fiber C-ring tracheal stent comprises the following concrete steps:

[0073] 1) Twist the carbon fiber bundles into carbon fiber ropes, select 3 bundles of 1.5k carbon fibers and twist them into ropes, and the diameter of the carbon fiber ropes is 0.1mm; among them, the carbon fiber bundles are not treated with resin removal, and the epoxy resin on the surface accounts for 10% of the carbon fiber mass. 0.8%.

[0074] 2) Weave 12 carbon fiber ropes into carbon fiber braided strips with a width of 8mm and a thickness of 0.8mm.

[0075] 3) The carbon fiber braided strip is heated, baked and shaped by the aid of the mold. During the baking process, the carbon fiber braided strip is simultaneously applied with tension along the axial direction and vertical pressure along the plane, and a steel needle (the head is a cone) is inserted on the surface of the carbon fiber braided strip. shaped steel needle) to set reserved holes to obtain a carbo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com