Multi-stage reaction micro-channel structure, micro-fluidic chip and heterogeneous reaction method

A multi-stage reaction and microfluidic technology, applied in the field of microfluidics, can solve problems such as difficult quantitative control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

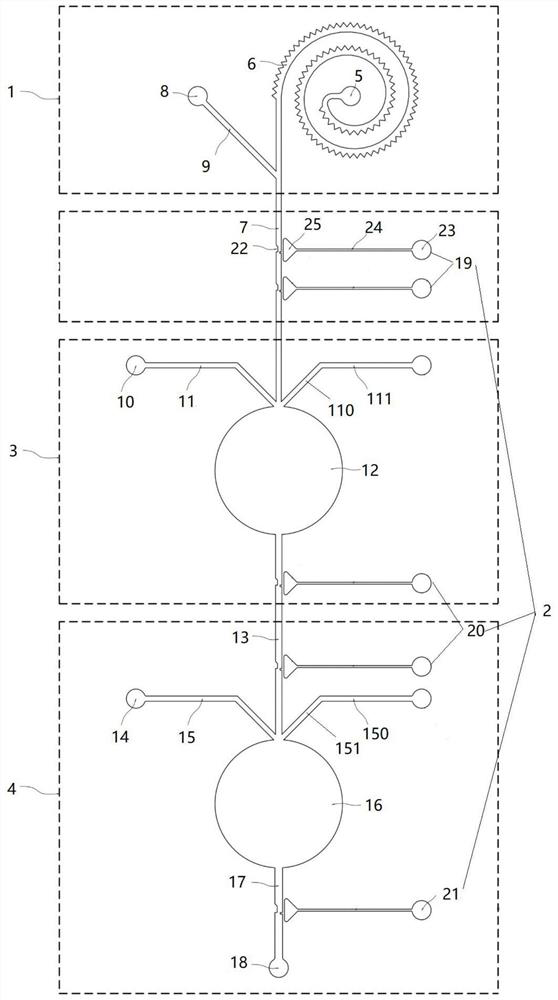

[0111] The above is the embodiment one provided by the application, and the following is the embodiment two provided by the application, specifically:

[0112] The material of the chip body is PDMS (polydimethylsiloxane), in which the length of the continuous outer triangular expansion focusing channel is 1200 mm, the distance between two adjacent vortex focusing channels is 100 μm, and the radius of curvature of the innermost channel is 40 mm. The width of the flow channel, the first reaction liquid phase flow channel, the continuous liquid phase flow channel and the second reaction liquid flow channel is 100 μm, the width of the first liquid outlet flow channel and the second liquid outlet flow channel is 100 μm, and the gas buffer chamber is The distance from the continuous liquid phase flow channel in non-working state is 60 μm, and the height of all flow channels is 150 μm. Nitrogen is selected as the gas phase, and an appropriate amount of carbon spheres with a particle ...

Embodiment 3

[0113] The above is the second embodiment provided by the application, and the following is the third embodiment provided by the application, specifically:

[0114] The material of the chip body is PDMS, in which the length of the continuous outer triangular expansion focusing channel is 1600mm, the distance between two adjacent vortex focusing channels is 80μm, the radius of curvature of the innermost channel is 50mm, the gas phase channel, the first reaction liquid phase flow The width of the channel, the continuous liquid phase channel and the second reaction liquid channel is 120 μm, the width of the mixed liquid phase channel and the liquid outlet channel is 160 μm, and the gas buffer chamber is kept in the non-working state with the wall of the liquid phase channel. A certain distance is 80 μm, and the height of all flow channels is 200 μm. Nitrogen is selected as the gas phase, and an appropriate amount of carbon spheres with a particle size of 50 μm is added to the mix...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com