High-precision large-pressure-reduction-ratio automatic pressure-regulating gas pressure-stabilizing and pressure-reducing combined valve

A technology of automatic pressure regulation and gas pressure stabilization, which is applied in the direction of the valve's device for absorbing fluid energy, device for pressure relief on the sealing surface, valve lift, etc., which can solve the problem of high cost, complex system, upstream and downstream anti-interference Poor ability and other problems, to achieve the effect of improving the ability to resist pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

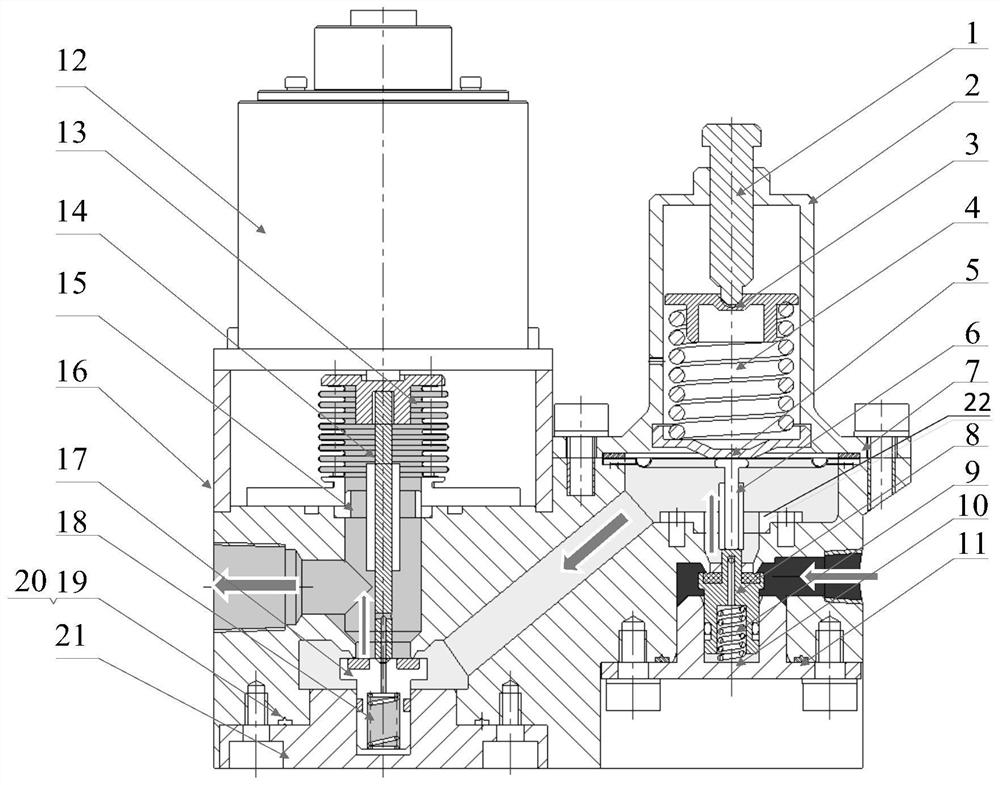

[0042] The present invention will be further elaborated below in conjunction with the accompanying drawings.

[0043] The present invention consists of figure 1 As shown, the integrated design is adopted, and all parts are installed on the substrate to form a highly integrated valve group.

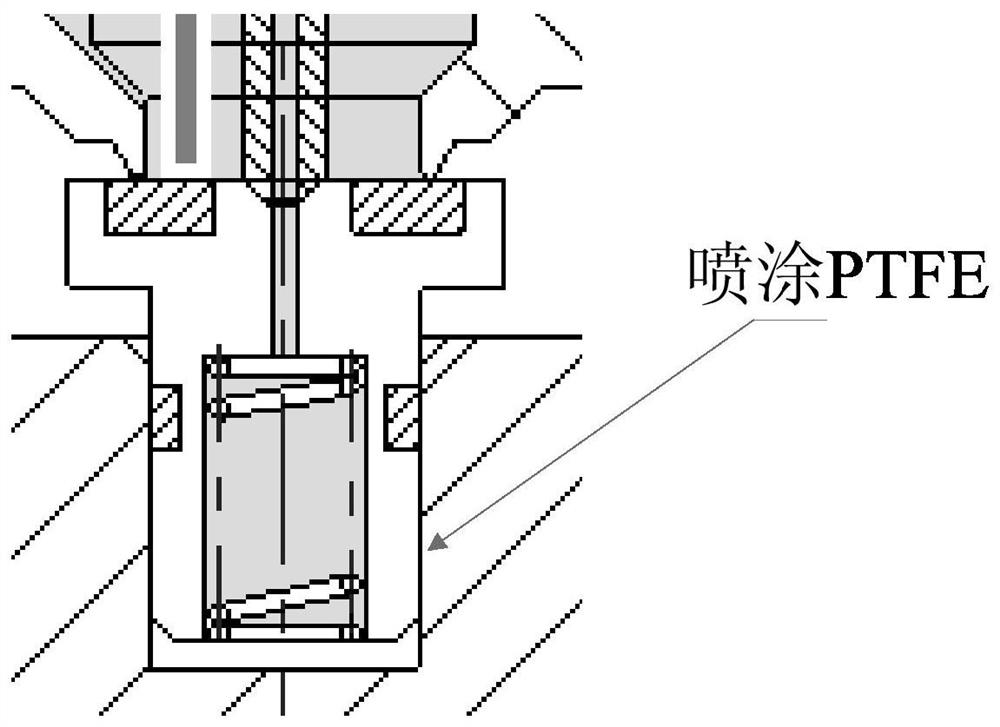

[0044] The primary valve assembly 8 is in the form of vulcanized rubber, and the fluorine rubber is vulcanized on the metal frame. The primary valve assembly 8 adopts a reverse unloading structure, and a cylindrical stepped cavity is processed inside, and the diameter of the upper cylindrical cavity is smaller than that of the lower end. The diameter of the cylindrical cavity is 0.8-1.1mm, and two oblique holes are opened at the boss on the top of the first-stage valve assembly. The diameter of the oblique holes is 0.5-0.8mm. The cylindrical stepped cavity in the direction runs through each other.

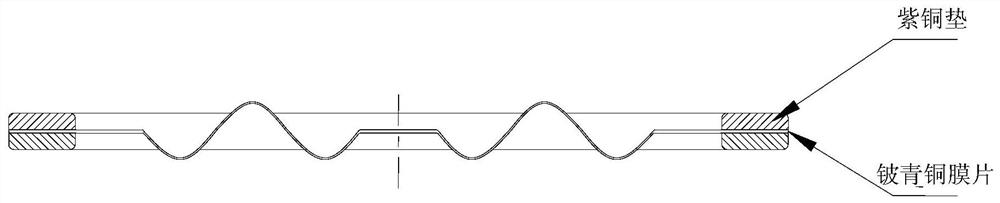

[0045] The primary valve assembly 8 has a sealing groove on the outer surface, and a seal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com