Fluid ejection device with reduced crosstalk

A technology of fluid jetting and fluid jetting, which is applied in the direction of inking device, hose connection device, printing, etc., can solve the problems such as adverse effects on printing quality, achieve reducing fluid crosstalk, stabilizing droplet size and speed, and accurate and precise printing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

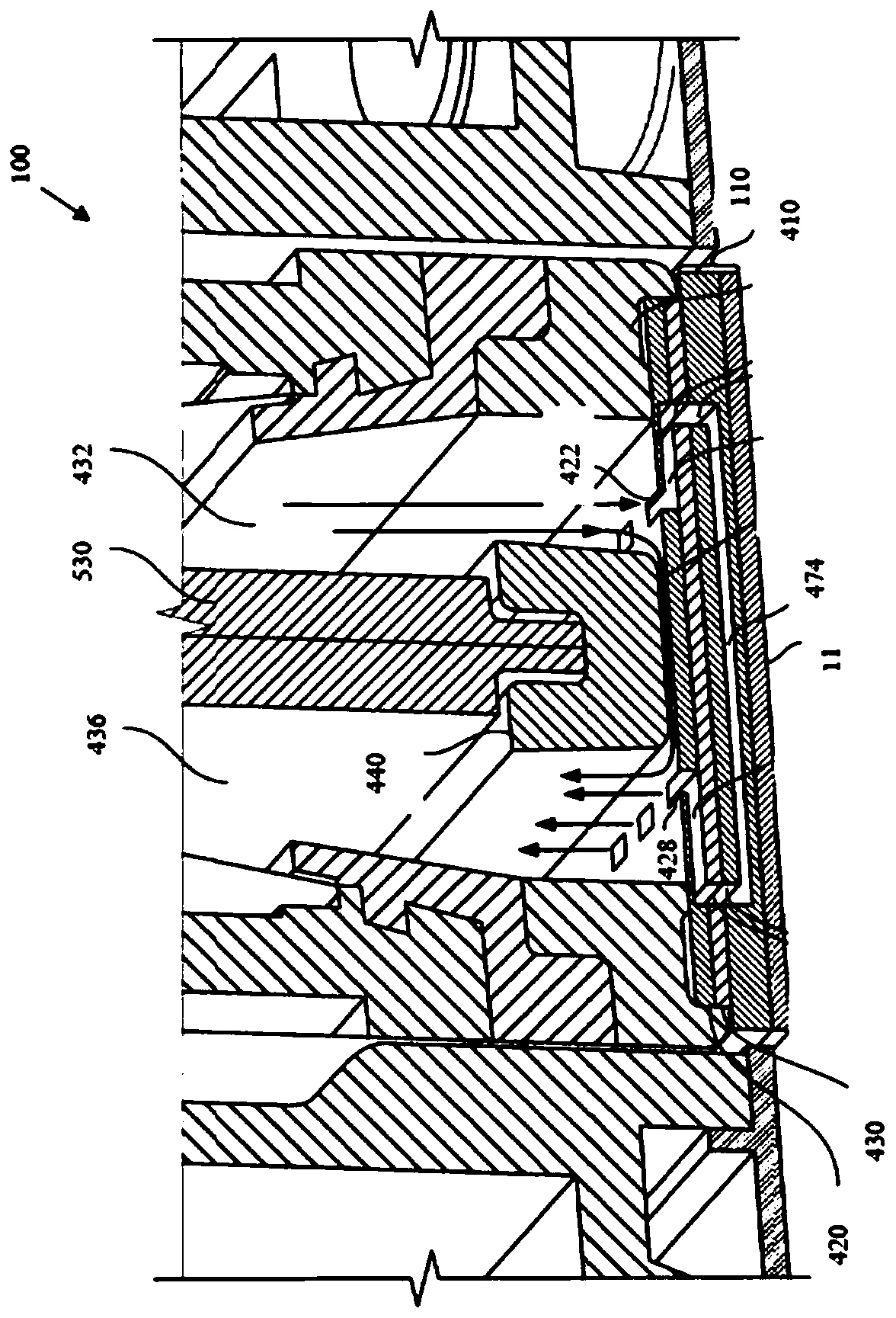

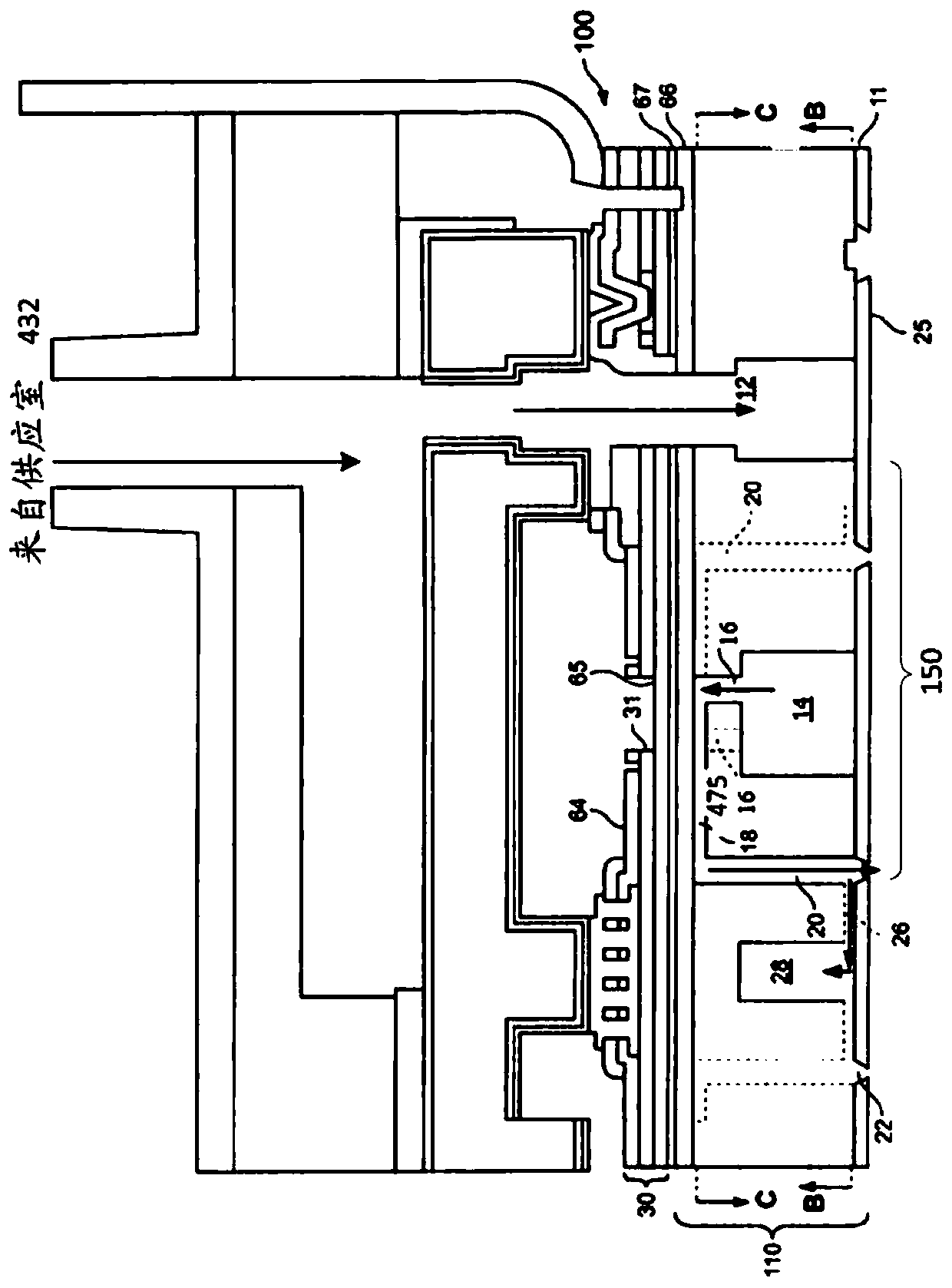

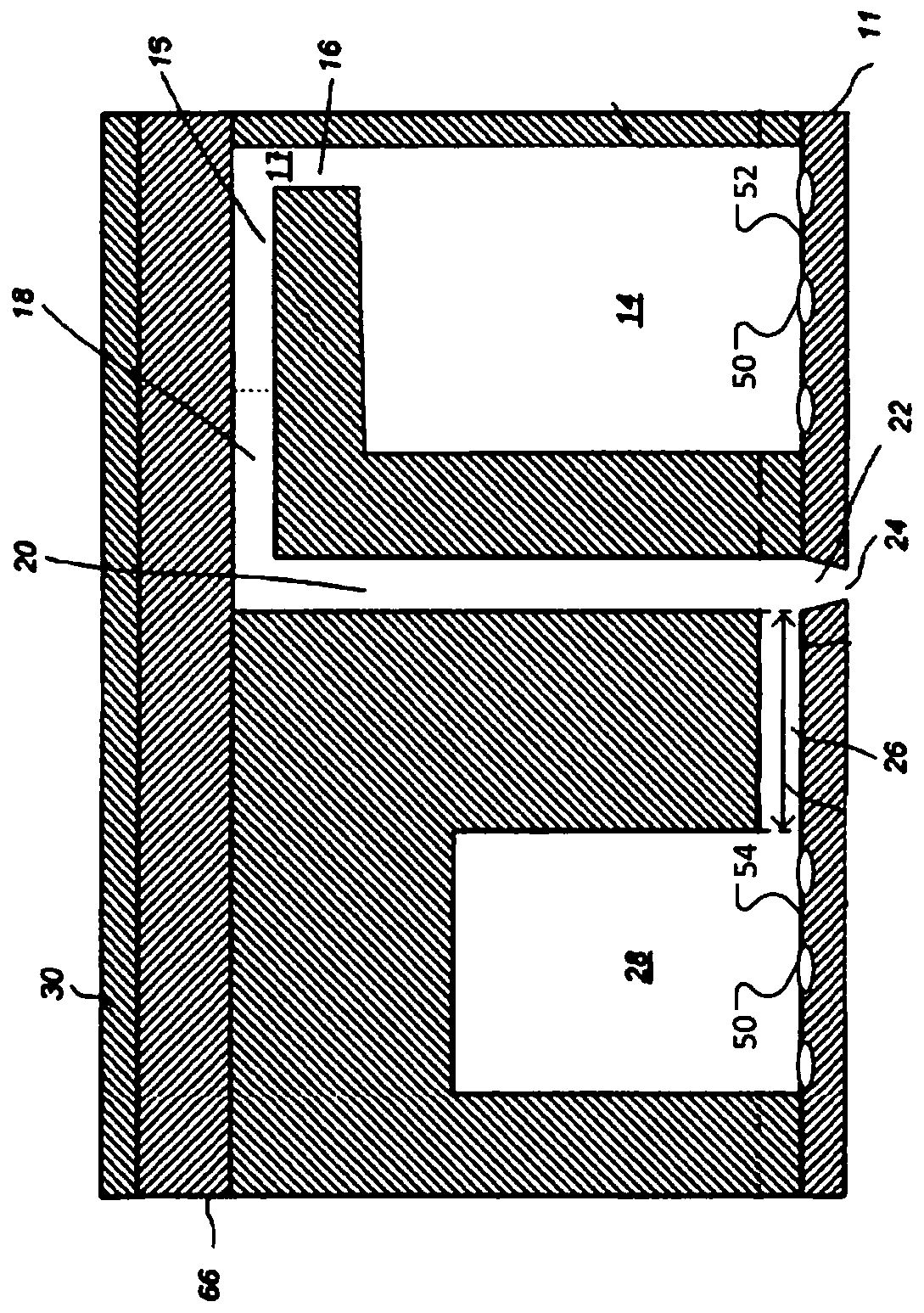

[0036] refer to figure 1 , the printhead 100 may be used to eject fluid droplets such as inks, biological fluids, polymers, liquids used to form electronic components, or other types of fluids onto a surface. The printhead 100 includes a housing 410 having an interior volume that is divided into a fluid supply chamber 432 and a fluid return chamber 436 , for example by an upper partition 530 and a lower partition 440 .

[0037] The bottoms of the fluid supply chamber 432 and the fluid return chamber 436 are defined by the top surface of the insert assembly. The insert assembly may be attached to the lower printhead housing 410, for example, by adhesive, friction, or other attachment mechanisms. The insert assembly may include an upper insert 420 and a lower insert 430 between the upper insert 420 and the base plate 110 .

[0038] Upper insert 420 includes a fluid supply inlet 422 and a fluid return outlet 428 . For example, fluid supply inlet 422 and fluid return outlet 428...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com