Piezoelectric crystal fuel injector driving circuit

A technology of piezoelectric crystals and driving circuits, which is applied in the direction of machines/engines, electrical controls, engine components, etc., and can solve problems such as fast current change rate, long response time, and high load on single-chip microcomputers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

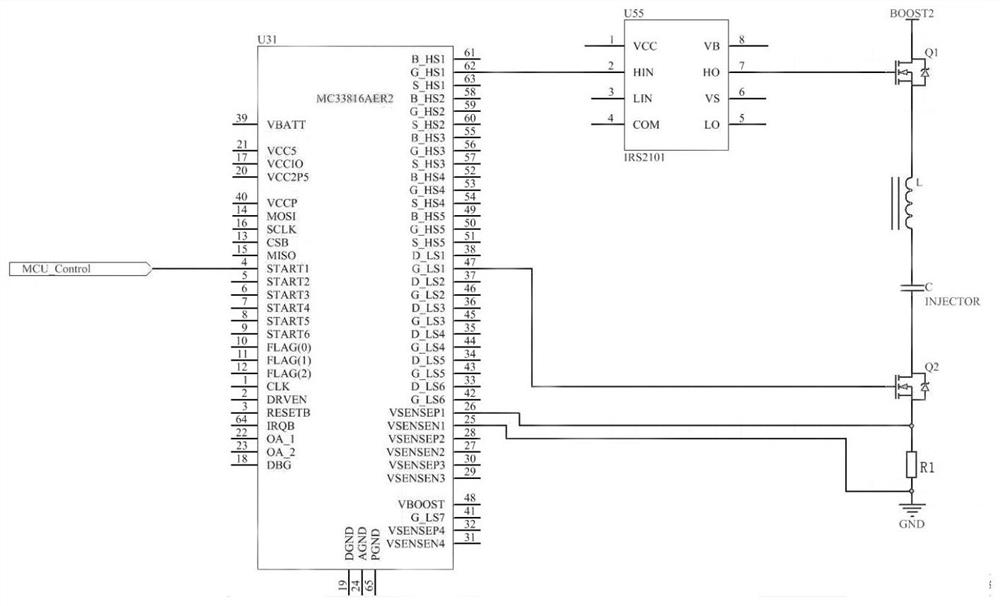

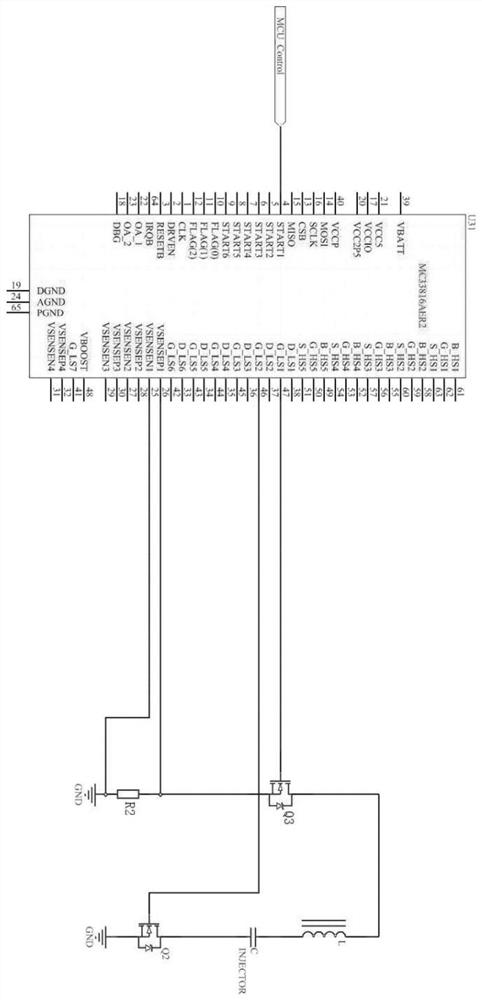

[0018] figure 1 As shown, it includes: a piezoelectric crystal charging circuit, and the piezoelectric crystal charging circuit includes: a pre-driver chip, a boost pre-driver chip, a MOS transistor Q1, a MOS transistor Q2, a piezoelectric crystal equivalent load C and a sampling resistor R1, The I / O interface of the pre-driver chip is connected to the microcontroller, the output port of the pre-driver chip is connected to the G pole of the MOS tube Q2, the output port of the pre-driver chip is connected to the boost pre-driver chip to realize boosting, and the output port of the boost pre-driver chip is connected to the MOS The G pole of the transistor Q1 and the S pole of the MOS transistor Q1 are connected to the piezoelectric crystal equivalent load C, the other end of the piezoelectric crystal equivalent load C is connected to the D pole of the MOS transistor Q2, and the S pole of the MOS transistor Q2 is connected to the sampling resistor R1, the other end of the samplin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com