Hole transport material with excellent performance and organic electroluminescent device containing hole transport material

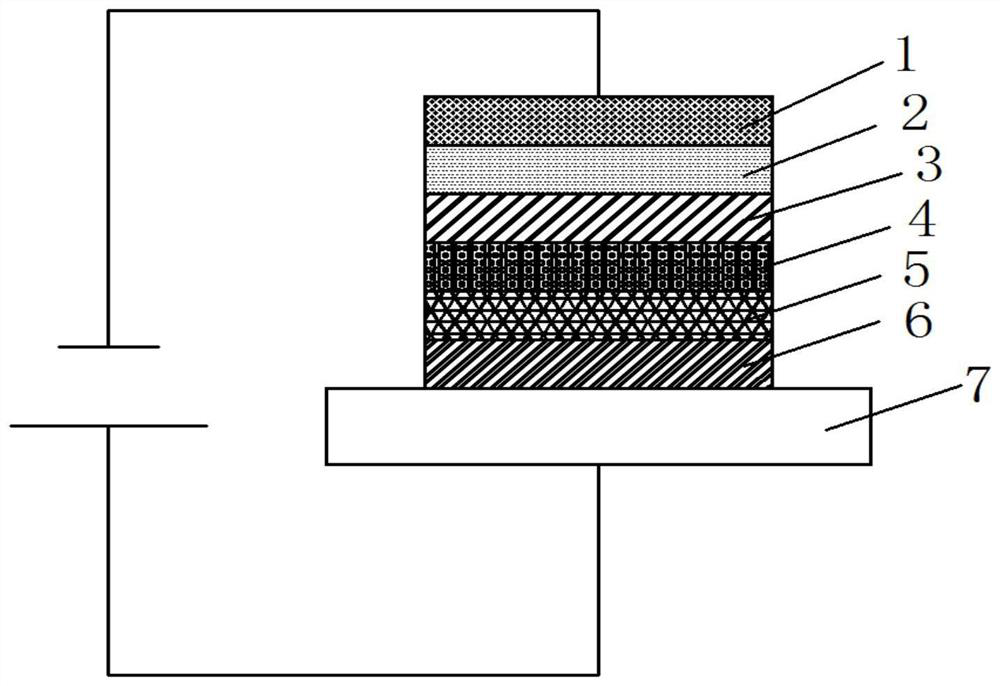

A hole transport material and luminescent technology, which is applied in the direction of electric solid devices, electrical components, organic chemistry, etc., can solve the problems of destroying the interface contact of the hole transport layer, destroying the uniformity of the film, and reducing the life of the device, so as to improve the hole The effect of increasing the hole migration rate, reducing energy consumption, and reducing the driving voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

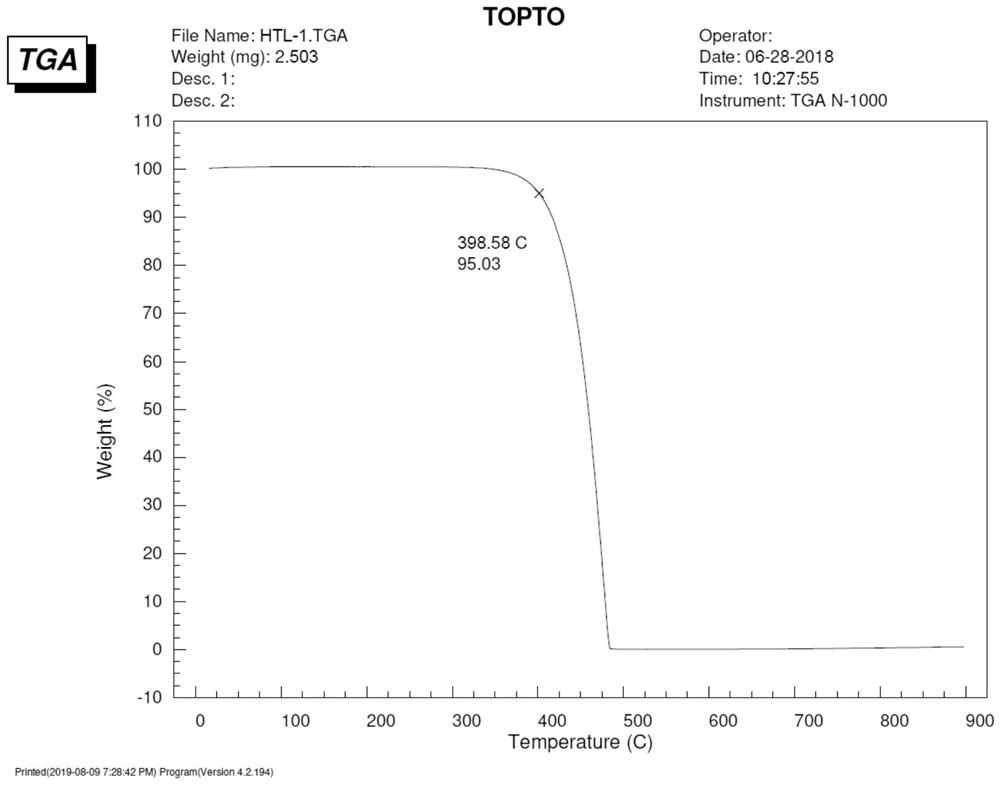

Embodiment 1

[0054]

[0055] The preparation method of the hole transport material (3) is as follows:

[0056] (1)

[0057]

[0058]Under nitrogen protection, compound 1-a (1.0g, 295.15g / mol, 3.4mmol), 1-b (1.1eq, 0.3g, 80.80.13g / mol, 3.74mmol) was dissolved in dioxane (20ml) , then KHMDS (2.5eq, 8.51mmol) 0.5M toluene solution (17ml) was slowly added dropwise, the temperature was raised to 90°C for 25h, cooled, the reaction solution was filtered, the filtrate was rotary evaporated, and purified by column chromatography to obtain compound 1-c (0.76g, yield 72.3%), MS (EI): 308 (M + );

[0059] (2)

[0060]

[0061] Under nitrogen protection, compound 1-c (0.6g, 309.20g / mol, 1.95mmol), compound 1-d (1.1eq, 0.69g, 321.41g / mol, 2.14mmol), sodium tert-butoxide (1.1eq, 0.21g, 96.1g / mol, 2.14mmol), tris(dibenzylideneacetone)dipalladium (0.05eq, 0.089g, 915g / mol, 0.097mmol), tri-tert-butylphosphine (0.05eq, 0.02g, 202.32 g / mol, 0.097mol), toluene (12ml) was added to the reaction fla...

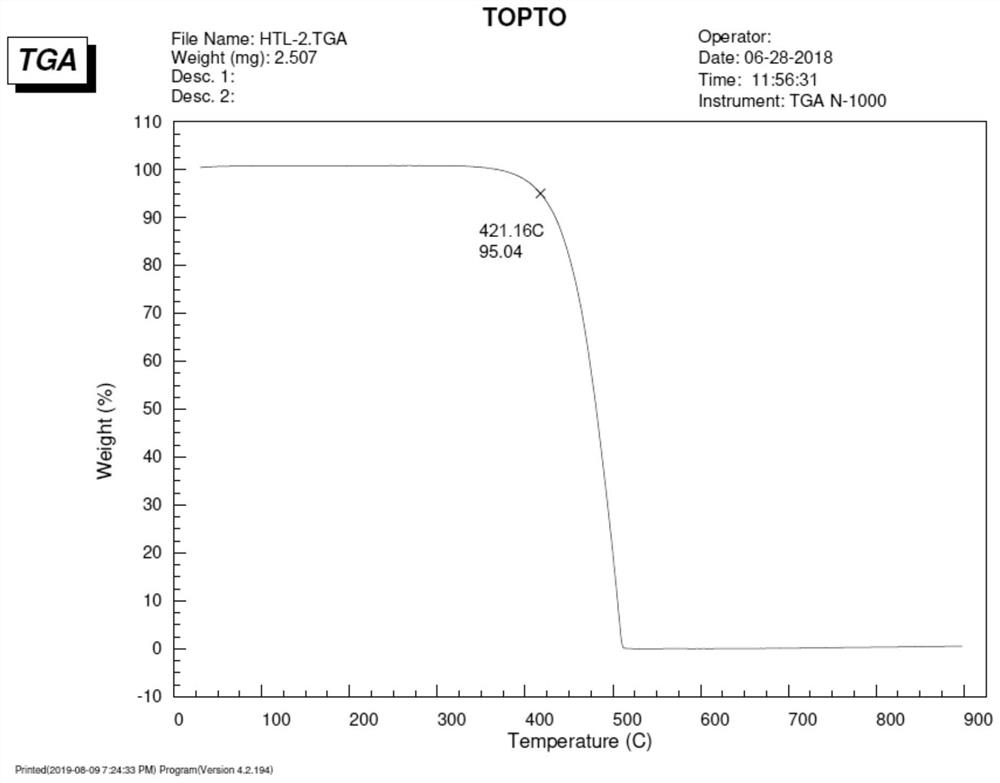

Embodiment 2

[0063]

[0064] The preparation method of the hole transport material (10) is as follows:

[0065]

[0066] Under nitrogen protection, compound 2-a (1g, 309.20g / mol, 3.25mmol), compound 2-b (1.1eq, 1.29g, 361.48g / mol, 3.57mmol), sodium tert-butoxide (1.1eq, 0.34 g, 96.1g / mol, 3.57mmol), tris(dibenzylideneacetone)dipalladium (0.05eq, 0.15g, 915g / mol, 0.16mmol), tri-tert-butylphosphine (0.05eq, 0.032g, 202.32g / mol, 0.16mol), toluene (20ml) were added in the reaction flask, after the addition was completed, the temperature was raised to reflux for 5 hours, after the reaction was completed, the temperature was lowered to room temperature, and 20ml of water was added and stirred for 15 minutes to obtain the filtrate, which was filtered through diatomaceous earth The organic phase was obtained by liquid separation, and the organic phase was dried with anhydrous magnesium sulfate and then spin-dried, and purified by column chromatography to obtain a hole transport material (10...

Embodiment 3

[0068]

[0069] The preparation method of hole transport material (16) is as follows:

[0070]

[0071] Under nitrogen protection, compound 3-a (1g, 309.20g / mol, 3.25mmol), compound 3-b (1.1eq, 1.46g, 410.51g / mol, 3.57mmol), sodium tert-butoxide (1.1eq, 0.34 g, 96.1g / mol, 3.57mmol), tris(dibenzylideneacetone)dipalladium (0.05eq, 0.15g, 915g / mol, 0.16mmol), tri-tert-butylphosphine (0.05eq, 0.032g, 202.32g / mol, 0.16mol), toluene (20ml) were added in the reaction flask, after the addition was completed, the temperature was raised to reflux for 5 hours, after the reaction was completed, the temperature was lowered to room temperature, and 20ml of water was added and stirred for 15 minutes to obtain the filtrate, which was filtered through diatomaceous earth The organic phase was obtained by liquid separation, and the organic phase was dried with anhydrous magnesium sulfate and then spin-dried, and purified by column chromatography to obtain a hole transport material (16) (1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com