Production equipment and production method for large-diameter polyethylene steel wire mesh reinforced composite steady-state pipe

A technology of reinforcing composite, steel mesh, applied in the direction of tubular items, other household appliances, household appliances, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

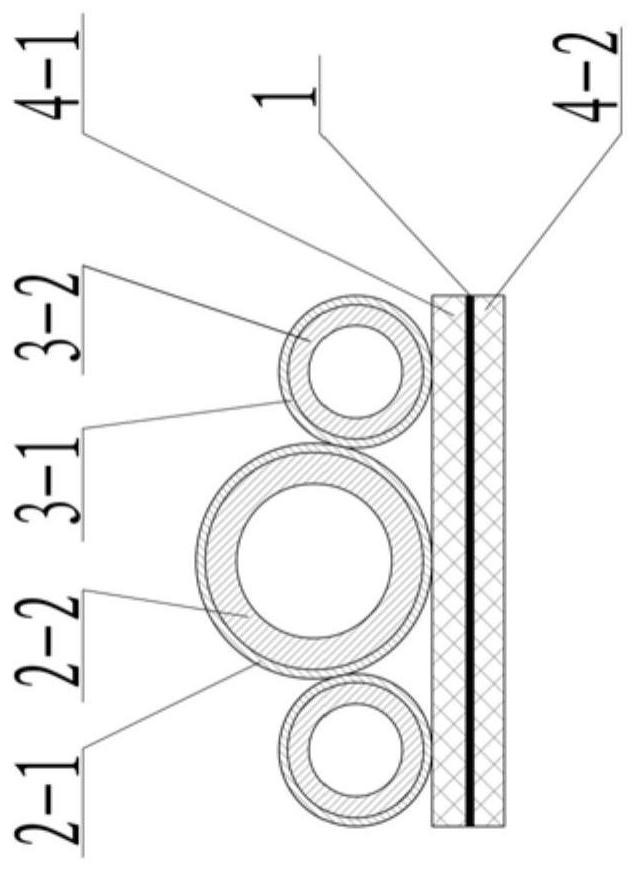

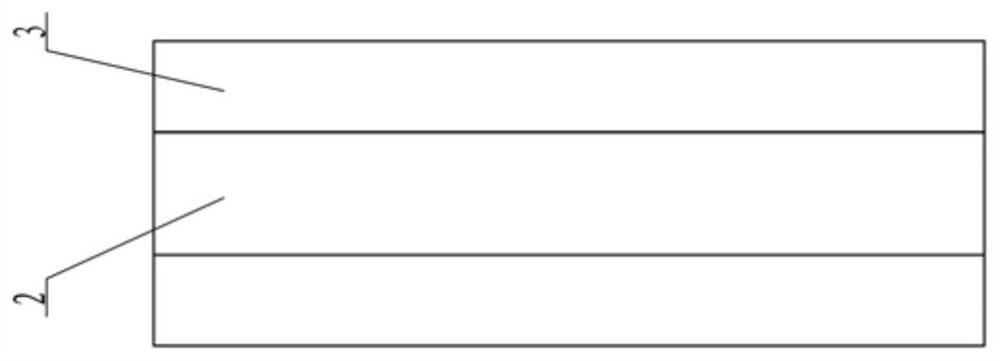

[0042] A production device for steel multi-reinforced composite pressure pipes, including forming machine A, heating device A-1, forming roller A-2, pressing roller A-3, reinforced pipe coating mold R-1, reinforced pipe coating extrusion Machine R, enhanced B tube unwinder - right B, enhanced A tube unwinder C, enhanced B tube unwinder - left D, tube wall outer layer extruder E, tube wall inner layer extruder F, sticky Connect resin extruder G, wire mesh unwinding machine H.

[0043]The connection relationship of the production equipment is: taking the forming machine A as the center, the reinforced tube coating mold R-1, the reinforced tube coating extruder R, the reinforced B tube unwinding machine-right B, the reinforced B tube unwinding machine are arranged at intervals in sequence. Coiling machine - right B, reinforced A tube unwinding machine C, reinforced B tube uncoiling machine - left D, tube wall outer layer extruder E, tube wall inner layer extruder F, adhesive resi...

Embodiment 2

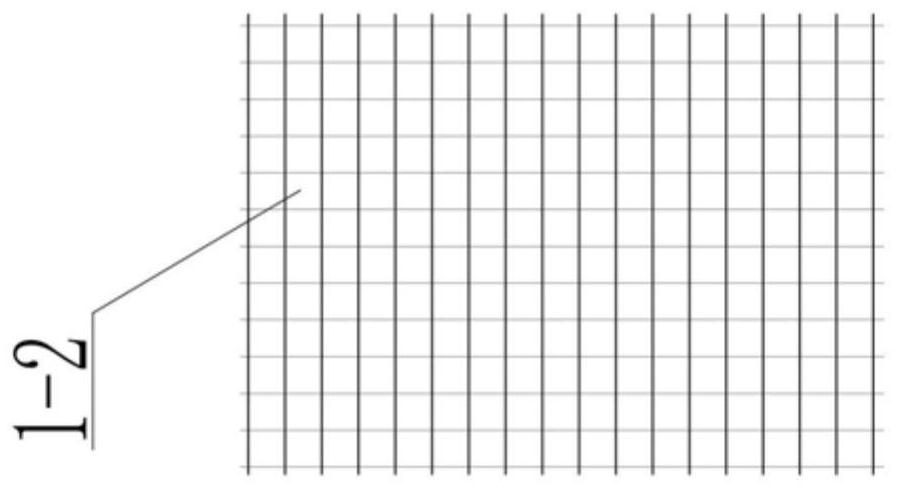

[0054] The steel wire mesh 1 is a rhombus steel wire mesh 1-2.

[0055] The reinforcing tube coating mold R-1 is successively 2 coating holes for reinforcing tube A and 3 coating holes for reinforcing tube B; the three holes are arranged horizontally side by side.

[0056] The rest is the same as above.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com