Foaming device achieving porous air intake and exhaust and foaming method of foaming device

A foaming device, air intake and exhaust technology, applied in the foaming device and its foaming field, can solve the problems of less steam inlet and steam outlet, uneven heating of foam particles, uneven heating of raw materials, etc., so as to improve quality and energy utilization. High rate, uniform temperature effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

[0030] Example.

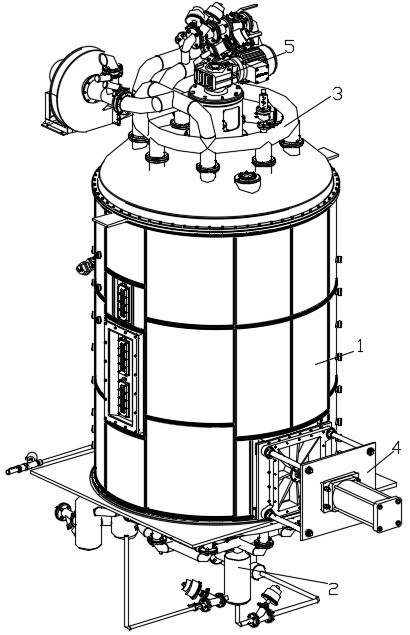

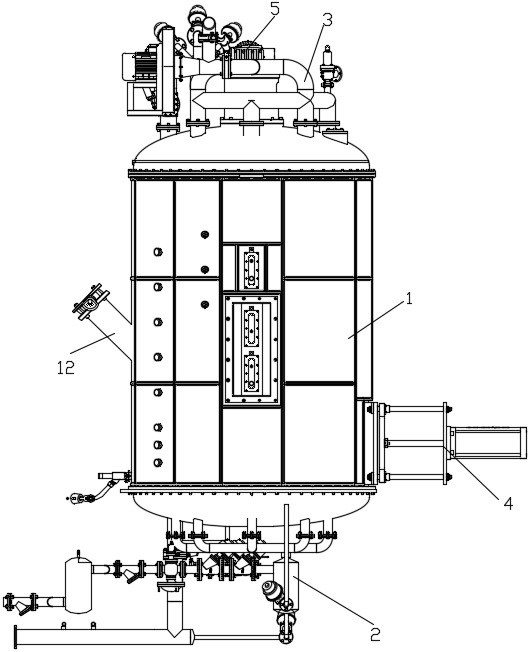

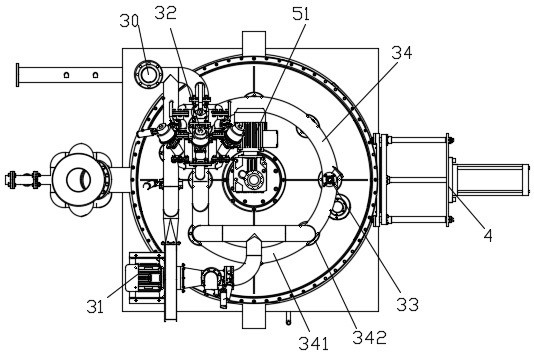

[0031] see Figure 1 to Figure 6 , the foaming device of porous intake and exhaust in the present embodiment comprises foam barrel 1, air intake mechanism 2, exhaust mechanism 3, material door cylinder 4 and stirring mechanism 5; Foam barrel 1 is provided with feed port 12 The intake mechanism 2 is installed at the bottom of the foaming barrel 1; the exhaust mechanism 3 is installed at the top of the foaming barrel 1;

[0032] The intake mechanism 2 in the present embodiment comprises a total intake pipe 20, No. 1 filter 21, No. 2 filter 22, No. 1 steam bag 23, No. 2 steam bag 24, No. 3 steam bag 25, pressure reducing valve 26, Steam proportional valve 27, air proportional valve 28 and porous air...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com