Denitration reactor hoisted by magnetic force

A technology of denitration reactor and reactor shell is applied in the field of denitration reactor, which can solve the problems of inconvenient installation of catalyst modules, limitation of reactor size, and inapplicability of denitration reactors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

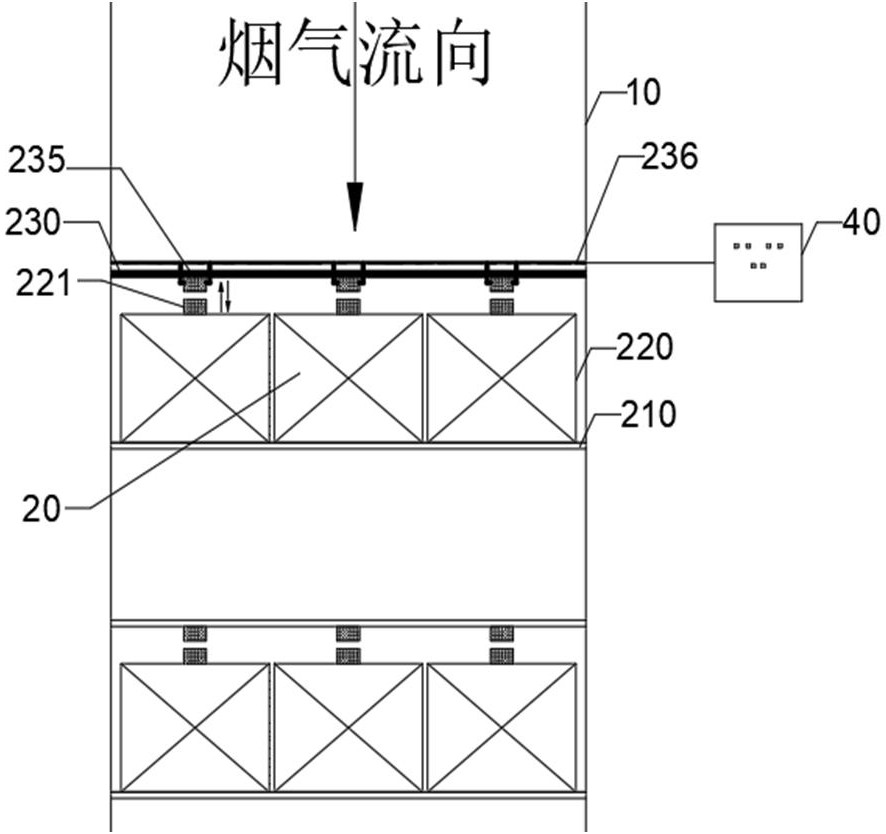

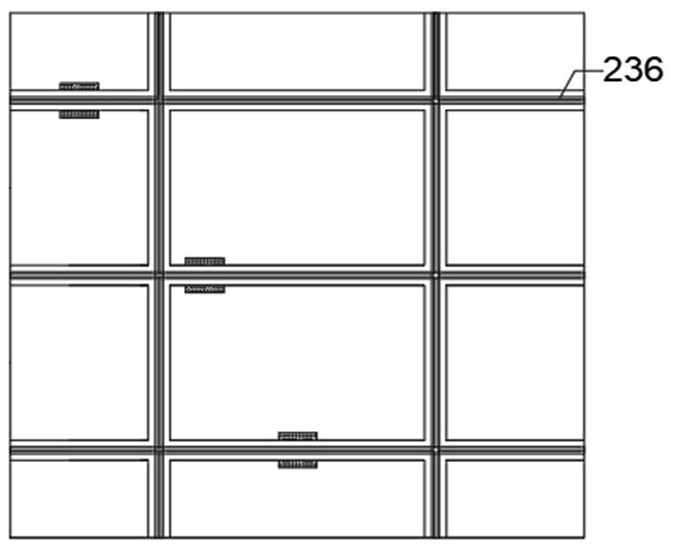

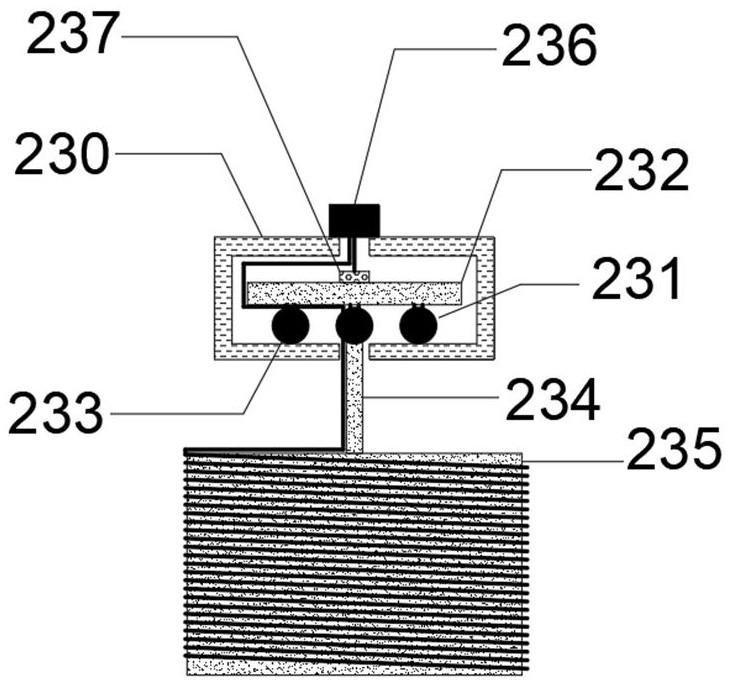

[0035] Such as Figure 1-6 As shown, a denitrification reactor using magnetic hoisting. In this embodiment, the SCR reactor is arranged vertically. The denitration reactor includes a vertically arranged cube-shaped reactor shell 10 and several catalyst beds 20 . The reactor shell can also be a polygonal or circular shell. Each catalyst bed layer includes a supporting beam 210 , a denitration catalyst module 220 and a catalyst lifting beam 230 . The projected center line of the catalyst hoisting beam 230 in the vertical direction passes through the center point of each catalyst module 220 , and the hoisting beam 230 communicates with the corresponding catalyst installation door 110 on the reactor shell of this layer.

[0036] Several hoisting trolleys 231 are arranged below (parts) of the hoisting beam. The hoisting trolley includes a car body 232 and a universal wheel set 233, a boom 234 is set at the center of the bottom of the car body, and the car body is connected to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com