Differential signal via hole and coupling capacitor impedance continuity design method, pcb board

A differential signal, coupling capacitor technology, applied in printed circuits, electrical components, circuit devices, etc., can solve problems such as impedance discontinuity, and achieve the effect of avoiding excessive impedance, highlighting substantive characteristics, and wide application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] Avoid the problem of small impedance caused by not hollowing out the reference ground layer of the coupling capacitor and directly hollowing out the adjacent ground layer.

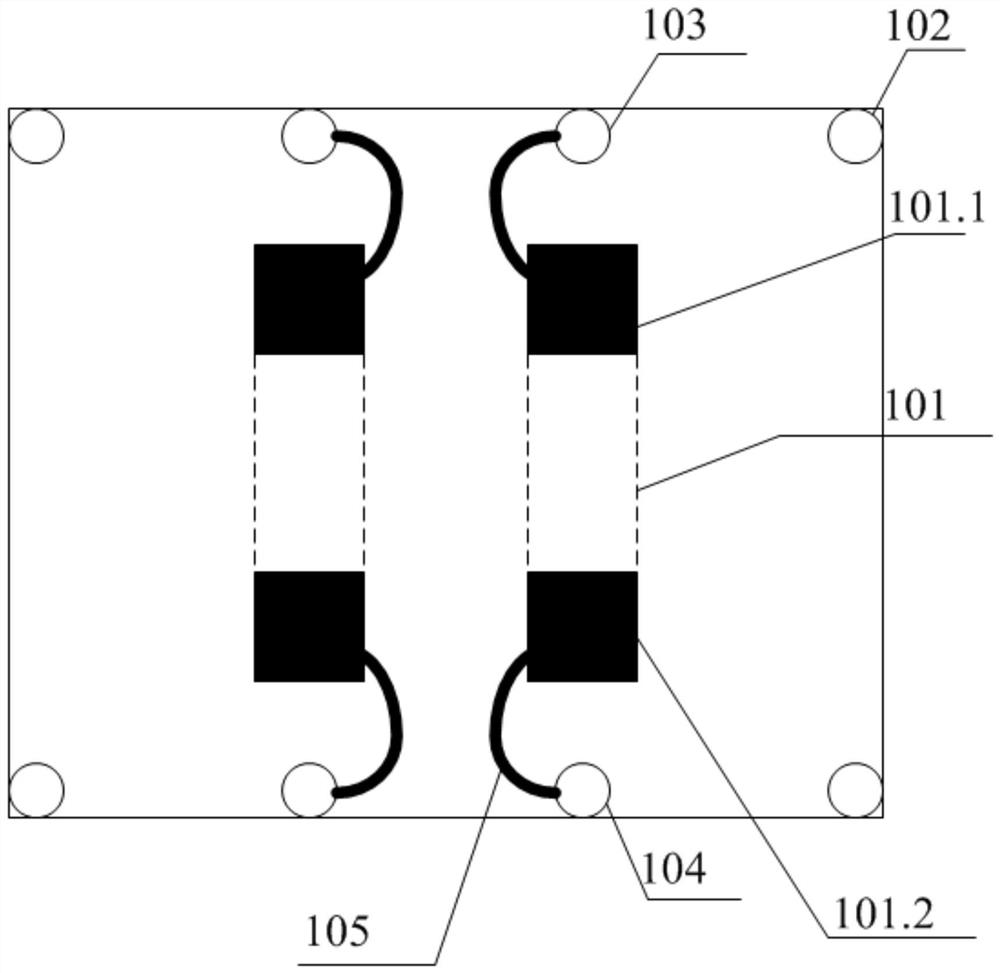

[0064] The component placement attribute is obtained, and the coupling capacitor 101 is placed on the top layer according to the placement attribute.

[0067] The impedance discontinuities of the signal vias and the coupling capacitors are combined into a design, which reduces the discontinuity of the discontinuities.

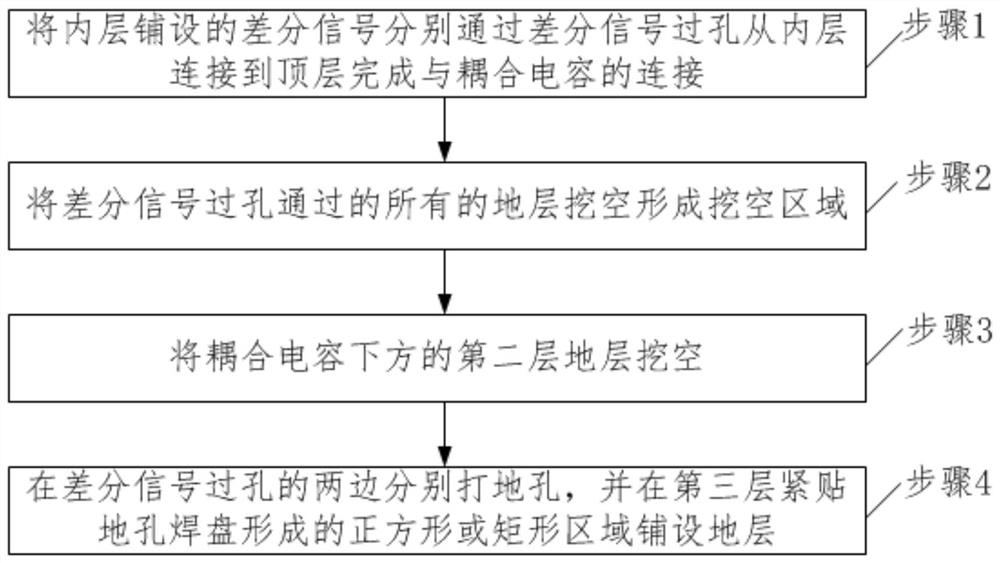

[0068] In some embodiments, the steps of hollowing out all the ground layers through which the differential signal vias pass to form a hollowed-out area include:

[0070] In some embodiments, the step of hollowing out the second layer of formation below the coupling capacitor includes:

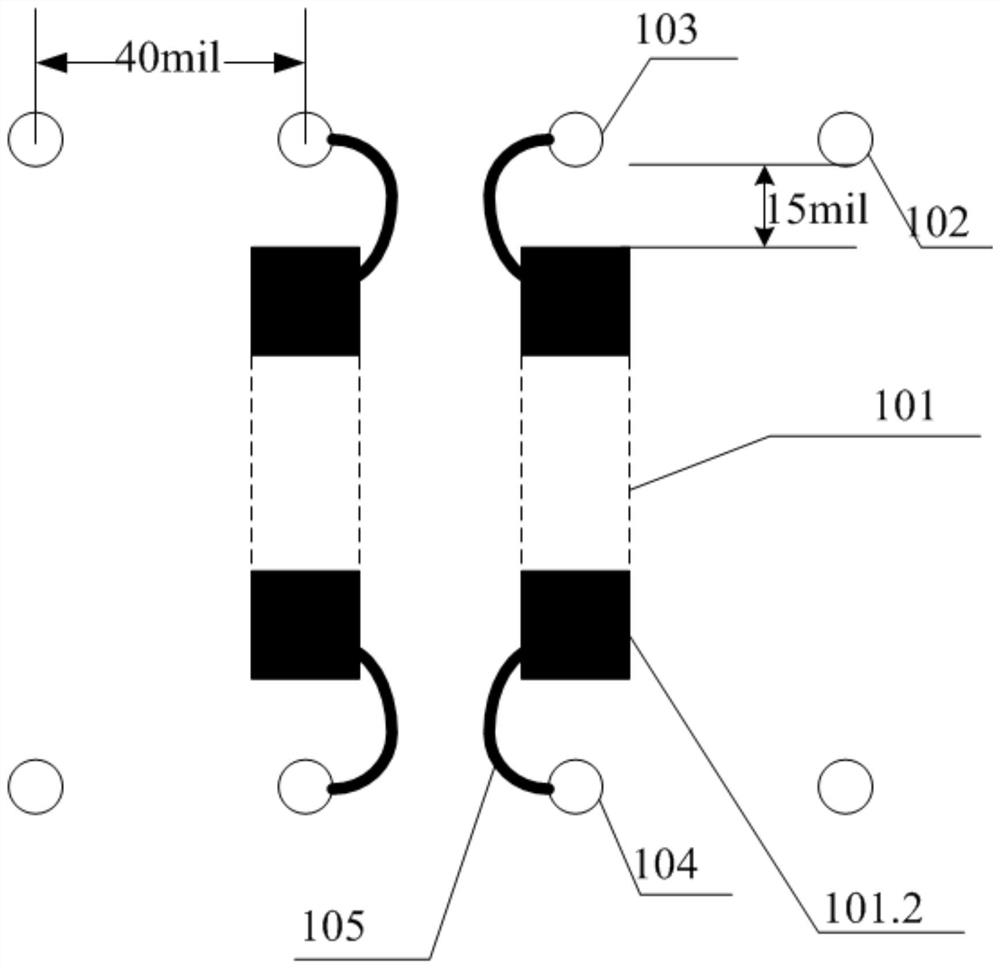

[0071] As shown in FIG. 4, the pad area of the coupling capacitor is hollowed out in the second ground layer; wherein, the coupling capacitor is hollowed out in the second ground layer

[0073] In some ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com