Flame-retardant special-shaped cable and forming equipment for flame-retardant layer of flame-retardant special-shaped cable

A molding equipment and flame-retardant layer technology, which is applied in the field of molding equipment for flame-retardant special-shaped cables and their flame-retardant layers, can solve the problems of unsuitable coating methods and injection methods, single flame-retardant methods for flame-retardant cables, and impacts on molding quality, etc. problems, to achieve stable and uniform hanging liquid volume, little impact, and improve the molding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

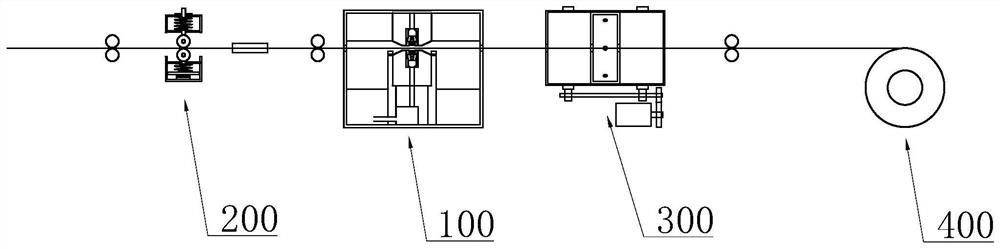

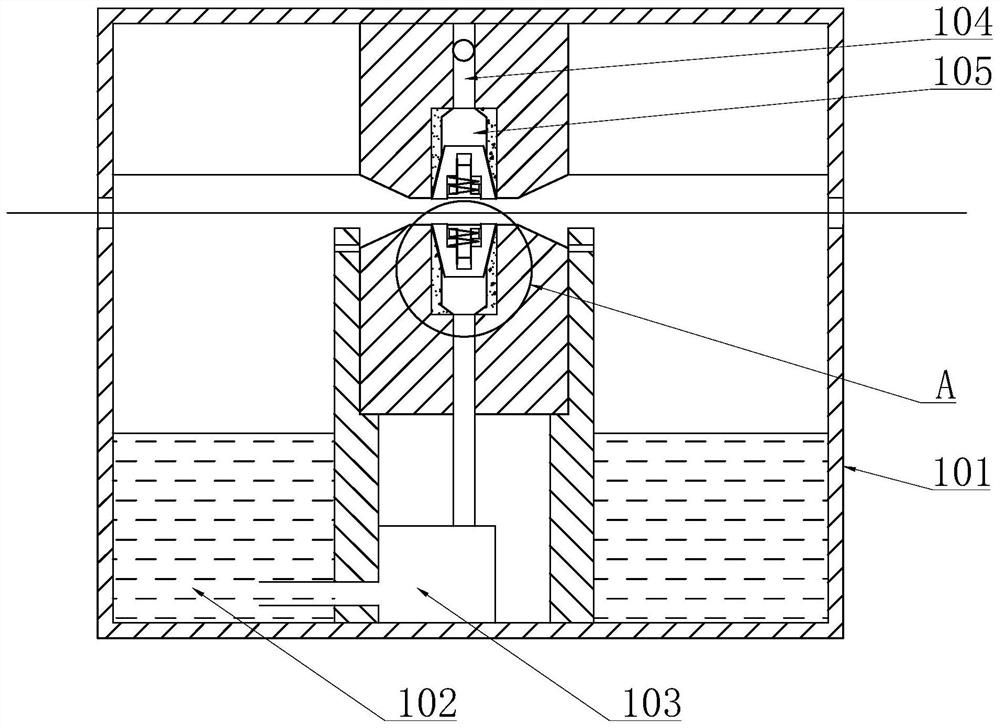

[0039] Below in conjunction with accompanying drawing, the present invention will be further described with specific embodiment, see Figure 1-8 :

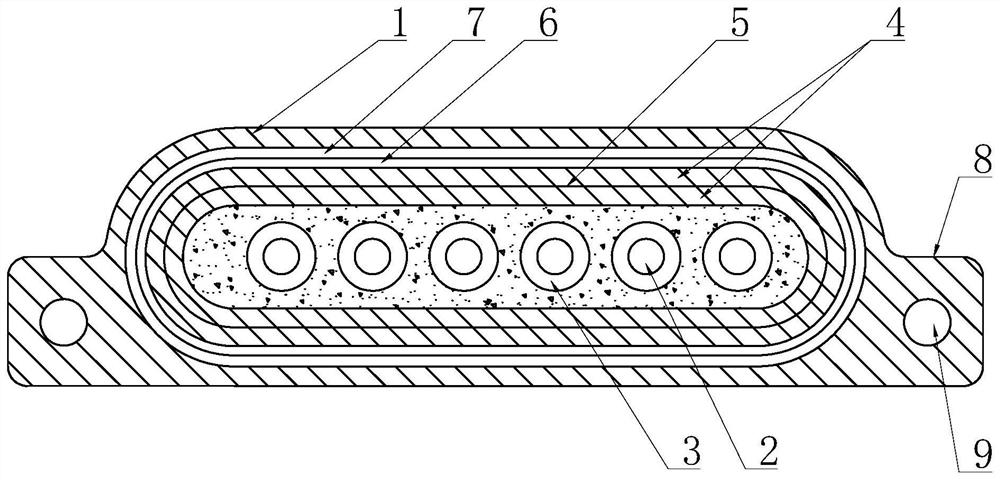

[0040] A flame-retardant special-shaped cable, including an outer sheath 1 and several wires placed in the outer sheath 1, the wires include a wire core 2 and an insulating layer 3 coated on the outer wall of the wire core 2, characterized in that: the outer The sheath 1 is also provided with an inner sheath 4 in a flat structure, and the wires are arranged horizontally and equidistantly in the inner sheath 4. The inner sheath 4 is a double-layer composite structure, and the inner sheath 4 is arranged between two layers. There is a mica tape winding layer 5, and a flame-retardant layer is also provided between the inner sheath 4 and the outer sheath 1. The flame-retardant layer includes a flame-retardant coating 6 coated on the outer wall of the inner sheath 4 and a spray and flame-retardant coating. Fire-retardant powder 7 on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com