Anti-vibration mechanism for imaging device, optical system, camera, and electronic equipment

A technology of imaging devices and optical systems, applied in optics, cameras, printing devices, etc., can solve problems such as necessity, increased design difficulty, difficulty in thinning, miniaturization, and difficulty in impact countermeasures, and achieves reduced design difficulty and constant The effect of relaxing the heart and suppressing natural vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0094] Hereinafter, the present invention will be described in detail with reference to the drawings.

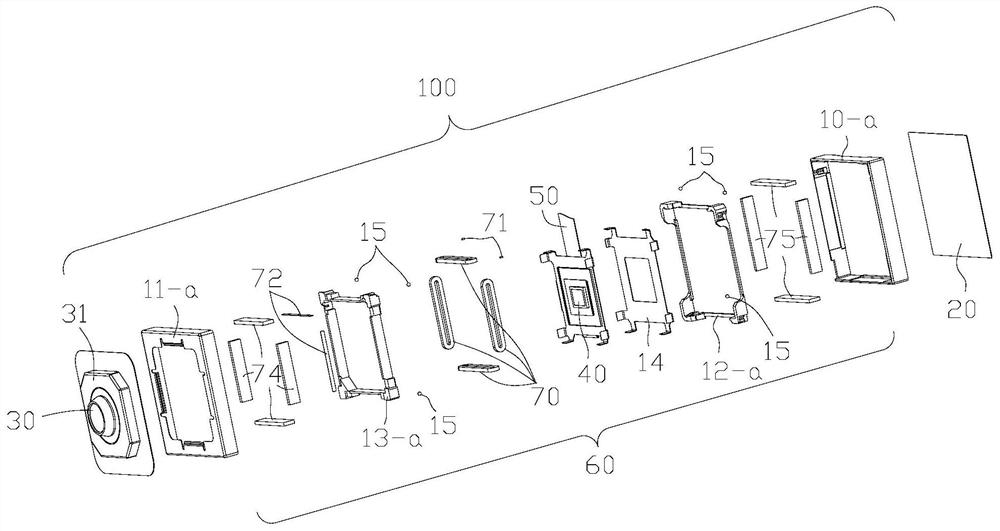

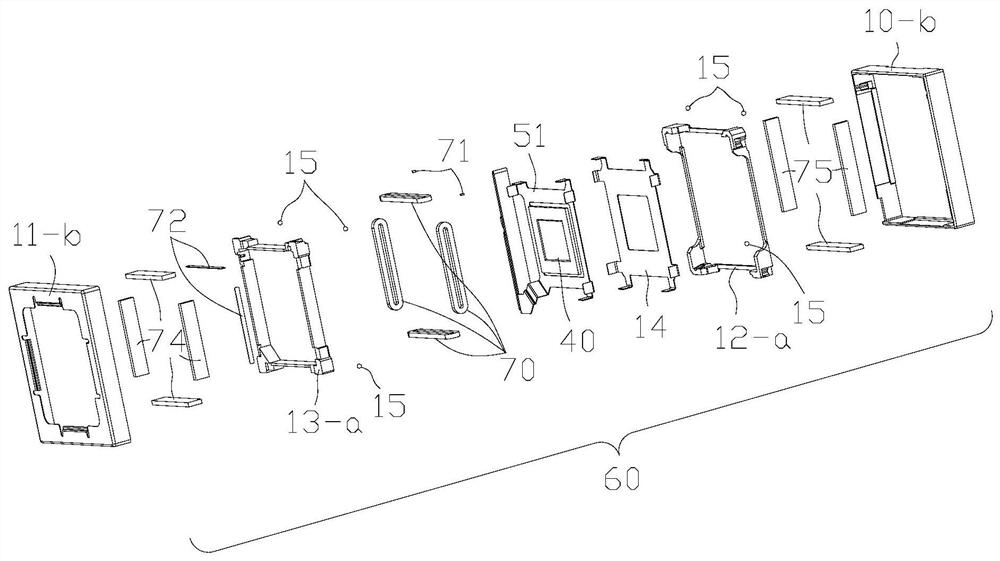

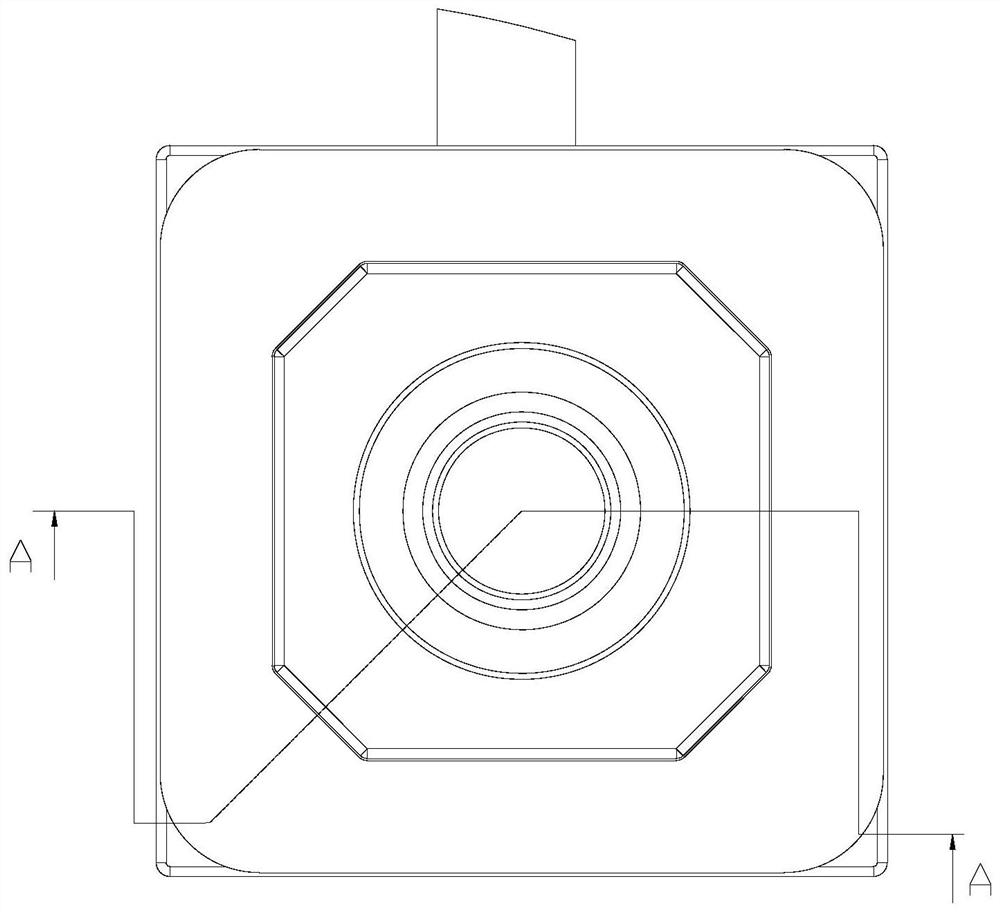

[0095] Figure 1 ~ Figure 4 It is a figure which shows the anti-vibration mechanism 100 for imaging devices of this invention, and the anti-vibration unit 60.

[0096] Figure 1 to Figure 12 An imaging device according to an embodiment of the present invention and its constituent elements are shown.

[0097] The imaging optical system of the anti-vibration mechanism 100 for an imaging device is composed of a lens 30, an autofocus mechanism 31 that drives the lens 30 and has a focus adjustment mechanism, or a telescopic zoom mechanism 32 that drives the lens 30 and includes a focus adjustment mechanism, and an imaging system from the object side. Optical system composed of elements 40.

[0098] The light beam from the subject that enters along the optical axis from the lens incident surface 30 - a of the lens 30 exits from the lens exit surface 30 - b and forms an image on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com