Slurry fluidity indoor testing device and method for deep well paste filling

A technology of fluidity and slurry, which is applied in the field of metal ore tailings paste pipeline filling research, can solve the problems of filling pipe wall wear, filling system not working normally, and low self-flowing conveying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

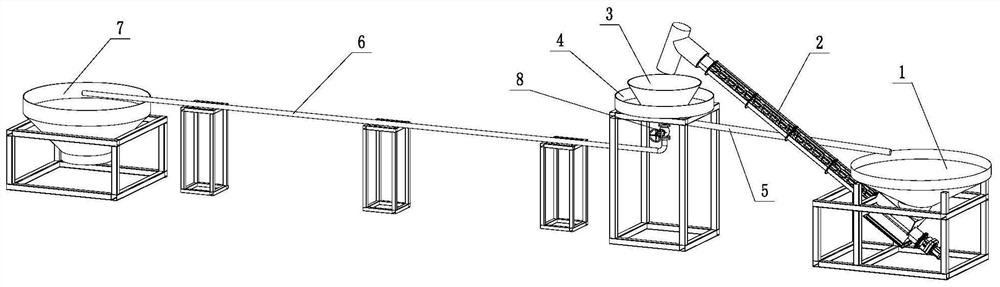

[0025] Such as figure 1 As shown, a slurry fluidity indoor test device for deep well paste filling includes a mixer 1, a screw conveyor 2, a material receiving funnel 3, a buffer tank 4, a slurry circulation pipe 5, a slurry delivery pipe 6 and Stirring tank 7; the mixer 1 is fixedly erected on the ground by a bracket; the buffer tank 4 is fixedly erected on the ground by a bracket, and the receiving funnel 3 is arranged at the inner center of the buffer tank 4, and the bottom of the receiving funnel 3 The outlet seal passes through the bottom of the buffer tank 4 and extends to the bottom of the buffer tank 4; the feed end of the screw conveyor 2 is connected to the discharge port at the bottom of the mixer 1, and the discharge end of the screw conveyor 2 is located at the receiving end Right above the funnel 3; the inlet of the slu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com