Experimental device and method for researching long-term soaking corrosion effect of shale and supercritical carbon dioxide

A carbon dioxide, experimental device technology, applied in measuring devices, using stable tension/pressure to test material strength, instruments, etc., can solve the problems of not taking into account the influence of deep shale stress, inability to deform and real-time monitoring of micro-fracture characteristics, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

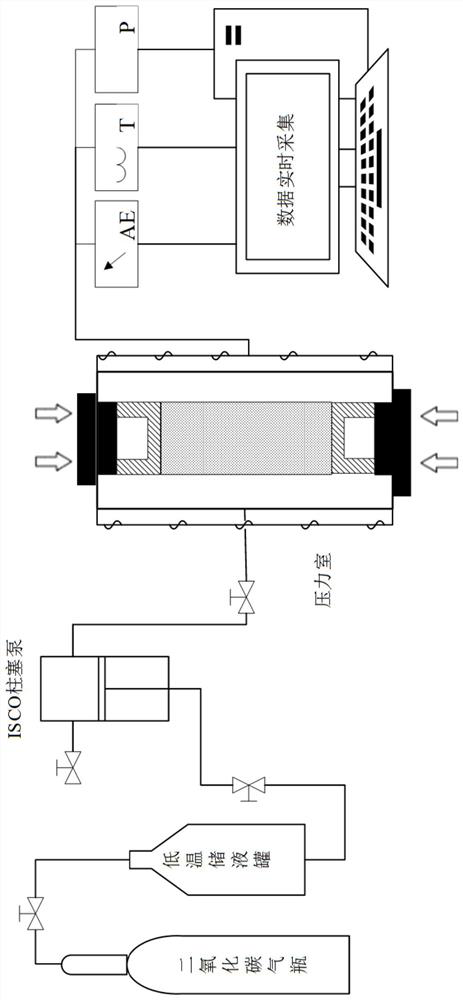

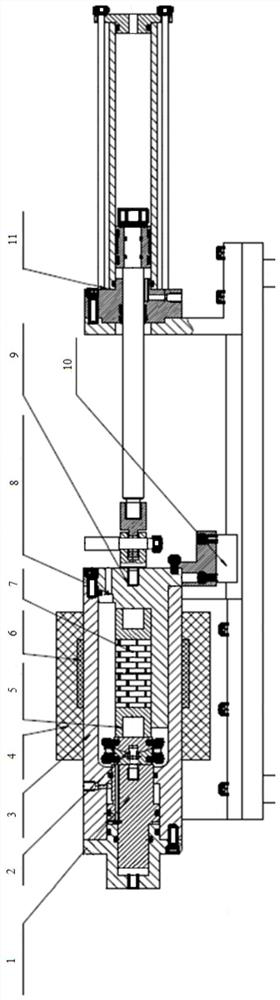

[0046] A deep shale supercritical carbon dioxide immersion-dissolution experiment device, the device is mainly composed of triaxial stress loading system, carbon dioxide pumping system, electromagnetic induction heating system, 16-channel core deformation measurement system, embedded acoustic emission monitoring system and The data acquisition system constitutes, such as figure 2 and image 3shown. The triaxial stress loading system is used to simulate the stress environment of deep shale; the carbon dioxide injection system is used to pump carbon dioxide into the acid-resistant self-balancing triaxial chamber; the electromagnetic induction heating system is used to simulate the stress environment of deep shale. high temperature environment; the 16-channel core deformation measurement system is used to measure the axial and radial deformation characteristics of samples under different immersion times; the embedded acoustic emission monitoring system is used to monitor the lo...

Embodiment 2

[0055] Utilize the device of embodiment 1 to carry out the method for deep shale supercritical carbon dioxide long-term immersion-dissolution experiment, comprise the following steps:

[0056] Step 1: Sample processing and preparation, first process the downhole full-diameter core into a cylinder with a diameter of 50mm and a height of 100mm, observe the surface bedding of the sample and the development of natural fractures, make records and weigh them;

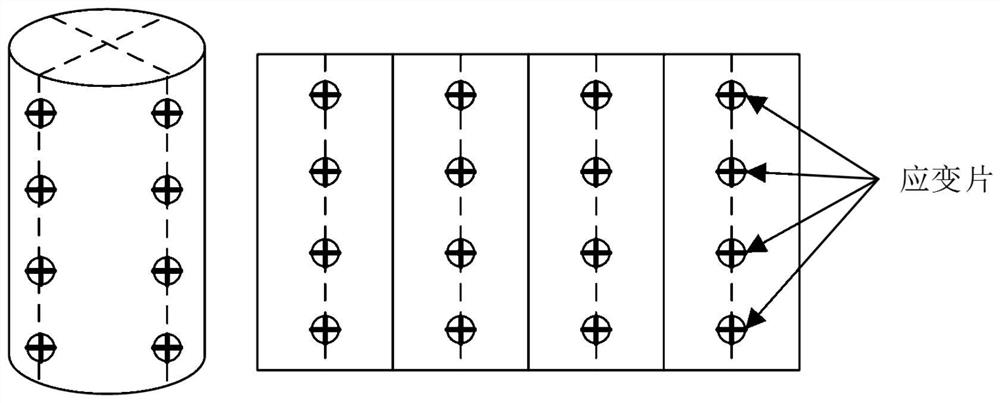

[0057] Step 2: If figure 1 As shown in , mark lines are drawn on the surface of the sample, and 16 strain gauges are attached to the specified positions in turn to test the radial and axial deformation at different positions during the soaking process of the sample;

[0058] Step 3: After the strain gauge is firmly pasted, place the sample in the triaxial chamber and fix it. At the same time, place the acoustic emission probe on the upper and lower ends of the sample, and lead the wire out to the monitor through the right end...

Embodiment 3

[0065] Using the device in Example 1 and the method in Example 2, long-term carbon dioxide immersion experiments were carried out on the Longmaxi Formation marine shale in the Sichuan Basin. Two rock samples were selected for the experiment, and the experimental sample numbers were WBL1 and WBL2.

[0066] The strain curve of shale-supercritical carbon dioxide immersion is shown in Figure 4 . The experimental results show that during the long-term immersion of supercritical carbon dioxide, the axial and radial deformation of shale increases significantly, accompanied by significant microfractures. For example, a very significant change of WBL1 during the soaking process is that a fracture runs through the shale surface, as shown in Figure 5 shown. Electron microscope analysis before immersion shows that there are no natural cracks in this area. The most obvious feature before and after immersion on the shale surface is that some minerals dissolve and disappear, and new por...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com