Shell-and-tube multi-pass heat exchanger

A heat exchanger, shell-and-tube technology, which is applied in the field of shell-and-tube multi-pass heat exchangers, and can solve problems such as easy failure of sealing devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

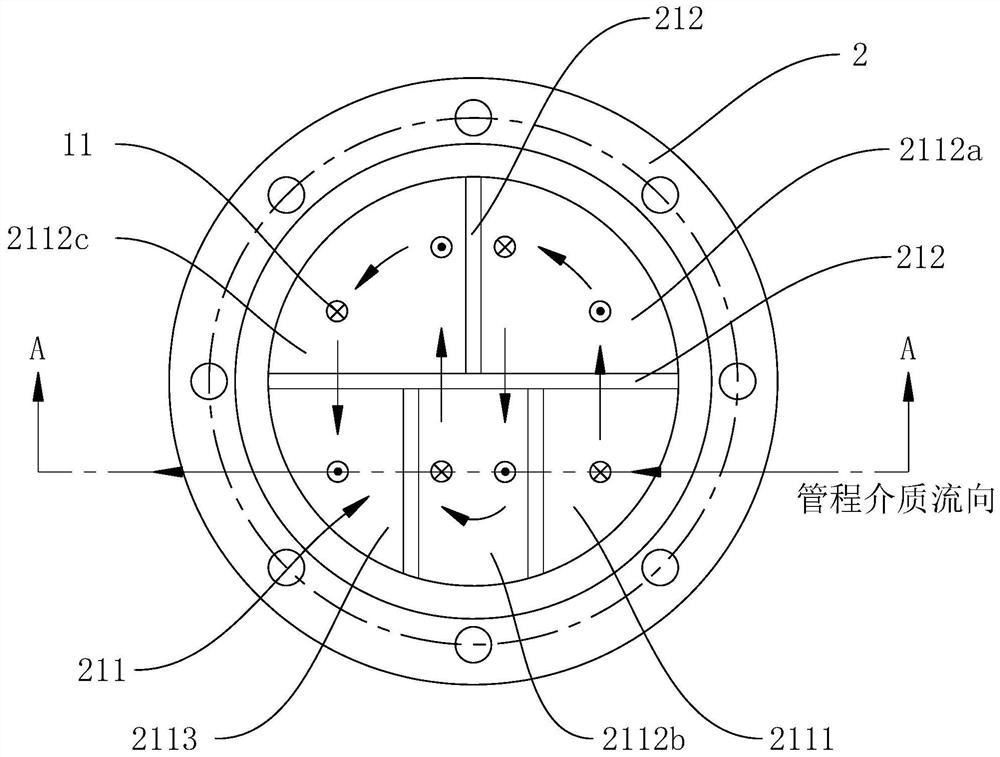

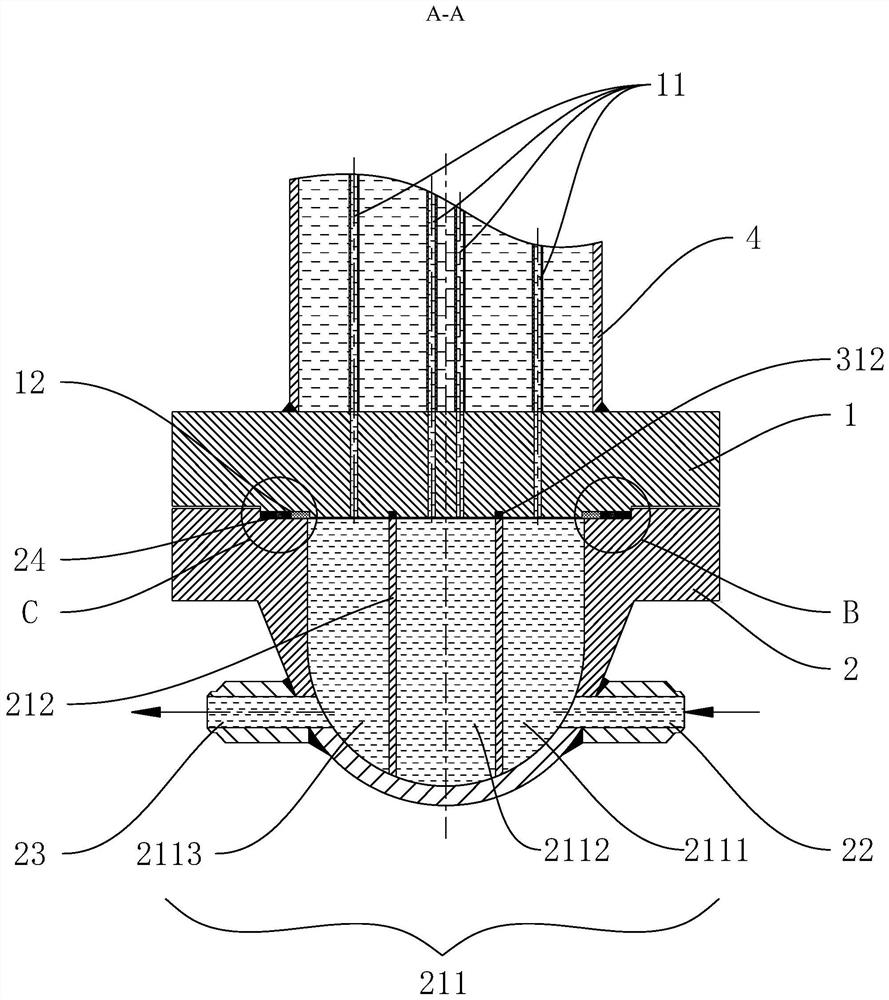

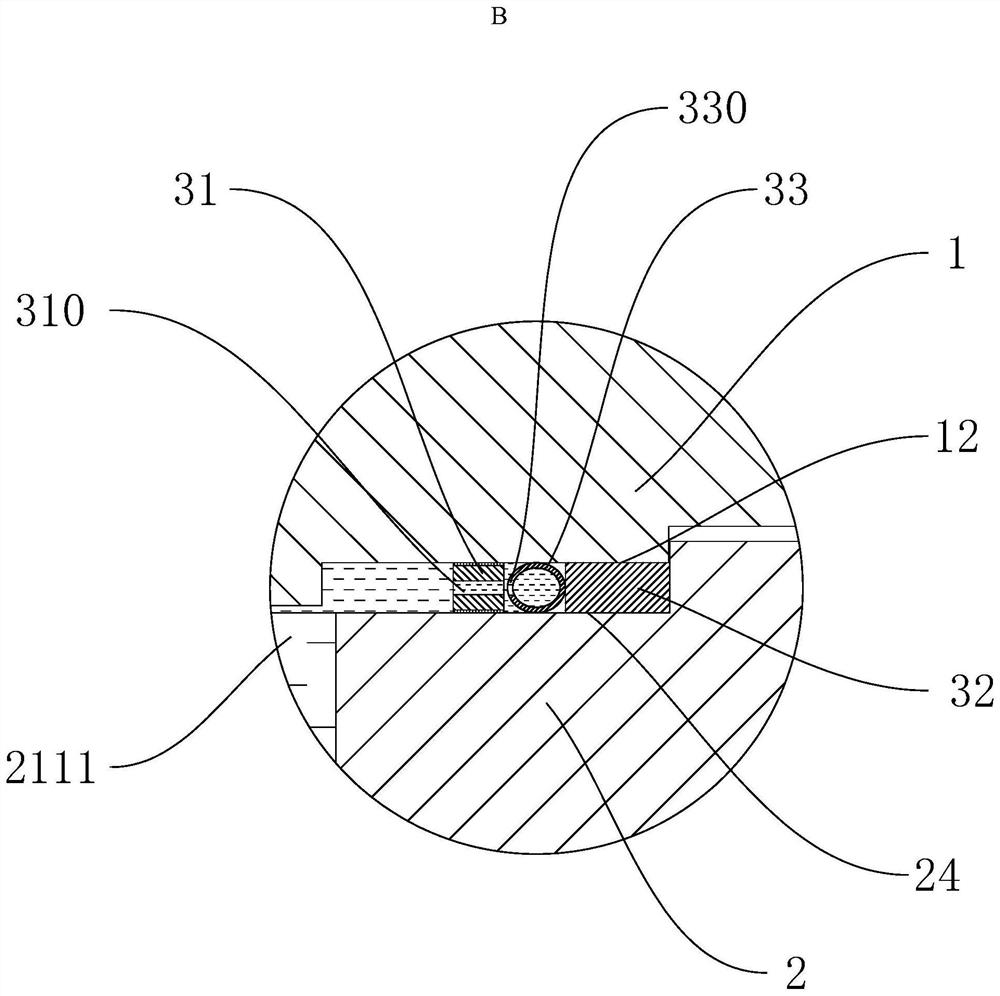

[0029] see figure 1 and figure 2 A shell-and-tube multi-pass heat exchanger is shown, including a first flange 1, a second flange 2 with a medium cavity, and an axial seal between the first flange 1 and the second flange 2 The connected sealing assembly 3, wherein the second flange 2 is specifically an autoclave with a flange connection portion, is referred to as the second flange 2 here for convenience.

[0030] The medium chamber includes a plurality of tube boxes 211 arranged on the second flange 2 and separated from each other, and the first flange 1 is provided with a plurality of heat exchange pipes 11 communicating with two adjacent tube boxes 211 . The heat exchanger also includes a shell-side shell 4 sealed with the first flange 1, the shell-side shell 4 and the first flange 1 form a multi-chamber cooler, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com