Device for applying lubricating grease to inner wall of pipeline

An oiling device and grease technology, which is applied in lubricating parts, engine lubrication, delivery pipes/joints, etc., can solve problems such as high viscosity of grease, heavy oiling labor, secondary pollution of products, etc., to ensure smearing Area, high oiling efficiency, effect of improving smearing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

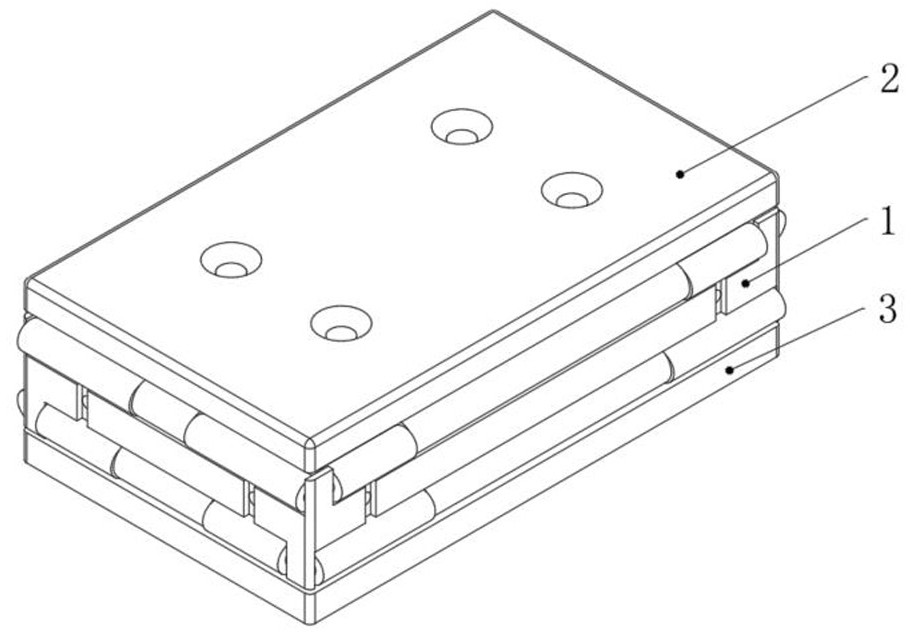

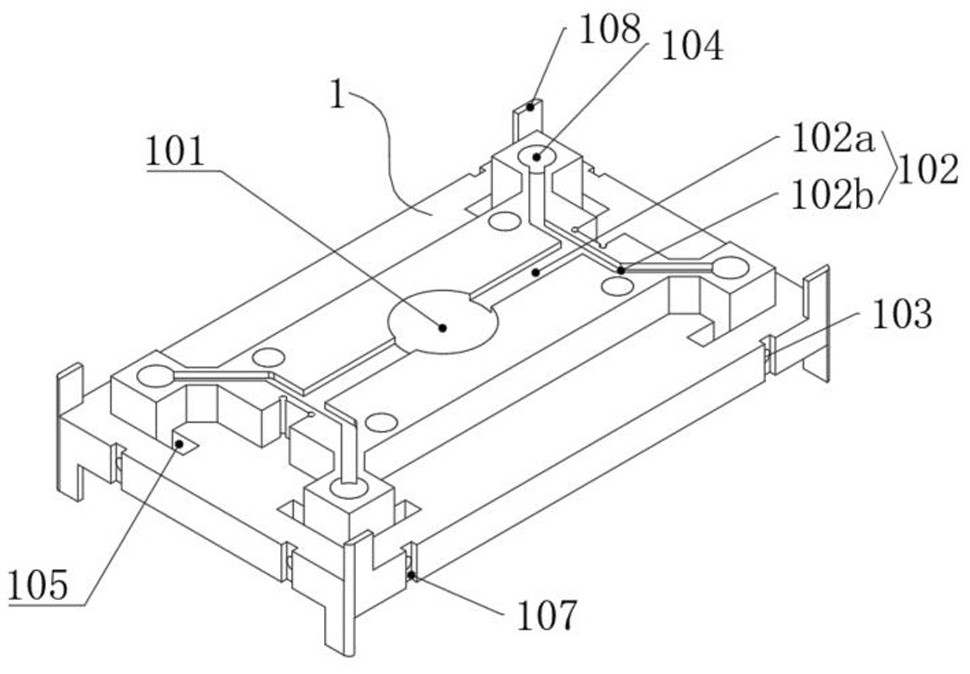

[0037] See Figure 1 to Figure 5 , The present invention has a main oil plate 1, a first cover plate 2, a second cover plate 3, and an elastic oiling mechanism 4. The main oil plate 1, the first cover plate 2 and the second cover plate 3 have a rectangular cross-sectional shape along the inside of the oiling pipe, and are suitable for painting the inner wall of the rectangular pipe.

[0038] The main oil plate 1 includes an oil inlet hole 101, a main oil plate flow channel 102, and an oil outlet hole 103. The oil inlet hole 101 is arranged on the main oil plate 1, and the main oil plate flow channel 102 is arranged on the main oil plate 1. There are 8 oil holes 101 and oil outlet holes 103, all of which are distributed on the main oil plate 1 side. The size of the main oil plate 1 is 2mm smaller than the inner wall size of the pipeline to be oiled.

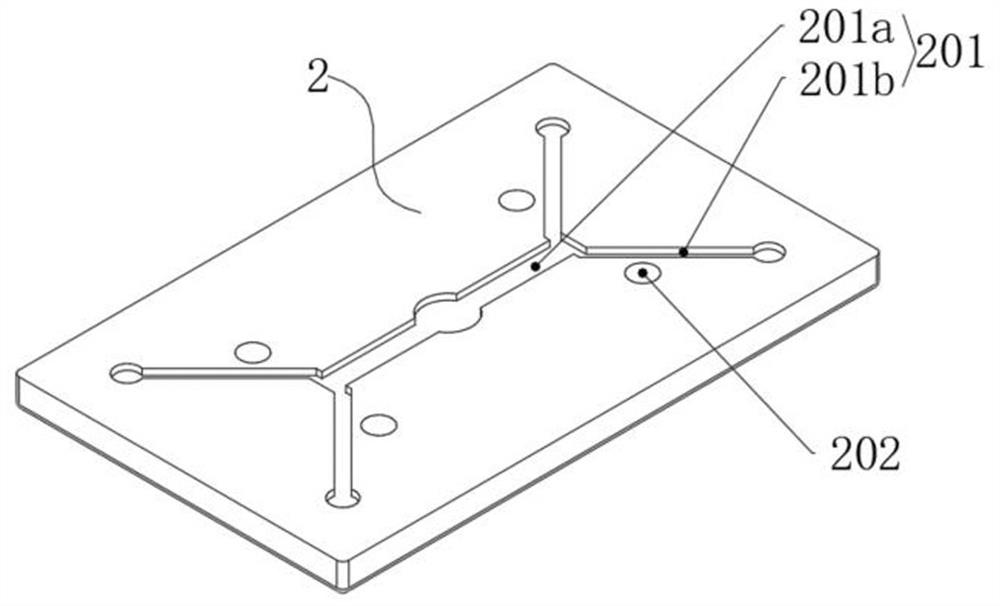

[0039] The first cover plate 2 is fixed above the main oil plate 1 .

[0040] The second cover plate 3 is fixed below the mai...

Embodiment 2)

[0051] See Figure 9 and Figure 10 , This embodiment is basically the same as Embodiment 1, and its distinguishing feature is that the cross-sectional shape of the main oil plate 1, the first cover plate 2 and the second cover plate 3 along the inside of the oiling pipe is a square, which is suitable for painting the inner wall of a square pipe.

Embodiment 3)

[0053] See Figure 11 and Figure 12 , this embodiment is basically the same as Embodiment 1, and its distinguishing features are: the cross-sectional shape of the main oil plate 1, the first cover plate 2 and the second cover plate 3 along the inside of the oiling pipe is an oblong hole shape, and the roller 403 at the arc-shaped end It is drum-shaped. Suitable for coating the inner wall of oblong hole tubes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com