Self-operated enclosure structure energy storage system based on gas-liquid-solid-liquid coupling phase change

A technology of enclosure structure and energy storage system, applied in air-conditioning systems, building components, heating methods, etc., can solve the problem of not being able to maximize the energy-saving benefits of phase change materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

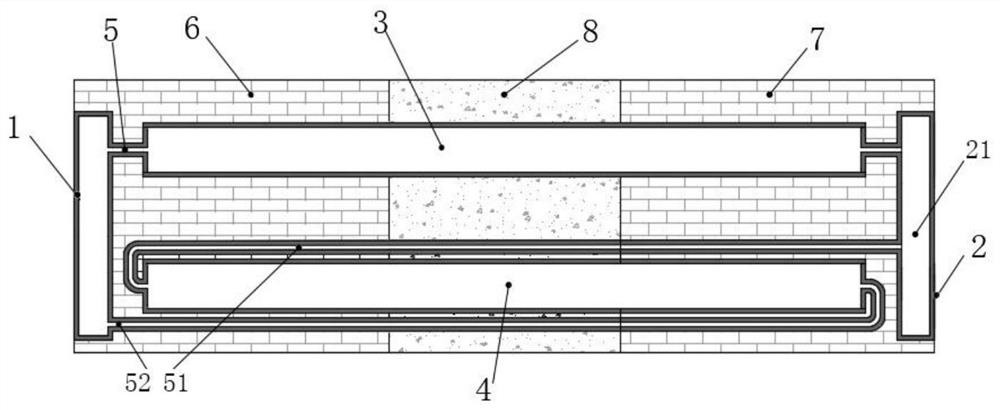

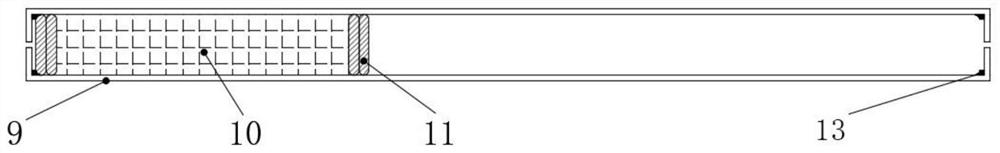

Embodiment 1

[0042] Such as Figure 4 As shown, the indoor temperature regulation of buildings in hot summer and warm winter and mild areas is dominated by refrigeration, so the summer energy storage tube 3 can be used alone in this area. According to the difference of indoor design temperature, the phase change temperature of the solid-liquid phase change material filled in the storage chamber can be selected within the range of 24-28°C. T wall,out Represents the external surface temperature of the wall, T wall,in Represents the inner surface temperature of the wall, P out Represents the pressure of the temperature sensing bulb outside the outdoor, P in Represents the pressure of the temperature sensing bulb inside the chamber, S represents the cross-sectional area of the piston / piston, F 0 represents the frictional resistance of the piston, F PCM Represents the frictional resistance between the solid-liquid phase change material and the inner surface of the energy storage tube she...

Embodiment 2

[0048] Such as Figure 5 As shown, in severe cold or cold regions, heating is mainly used in building interiors, so the winter energy storage pipe 4 can be used alone in this region. According to different indoor design temperatures, the phase change temperature of the solid-liquid phase change material 10 filled in the energy storage tube can be selected within the range of 16-20°C.

[0049] In the winter morning, when the outdoor temperature or the intensity of solar radiation starts to increase, so that the temperature of the outer surface of the outer wall is higher than the indoor temperature, the gas-liquid phase change material 21 in the outdoor temperature sensing package 1 evaporates and expands to form a relatively high pressure, which passes through the pressure guiding tube It is transmitted to the indoor side of the energy storage tube; the gas-liquid phase change material in the indoor temperature sensing package 2 condenses and shrinks to form a relatively low p...

Embodiment 3

[0054] Such as Figure 6-7 As shown, the region with hot summer and cold winter needs cooling in summer and heating in winter. In this area, the summer energy storage tube 3 and the winter energy storage tube 4 can be used in combination. According to the indoor design air-conditioning temperature and heating temperature, the energy storage tube 3 in summer and the energy storage tube 4 in winter can be filled with solid-liquid phase change materials with different phase change temperatures respectively.

[0055]In summer, the summer energy storage tube 3 works, and its working principle is the same as that of the summer energy storage tube 3 used alone. At this time, the low-temperature phase-change material filled in the energy storage tube 4 in winter is generally in a liquid state due to the low phase-change temperature, and the position of the solid-liquid phase-change material inside and outside the room will move with the temperature difference between indoor and outdoo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com