Metallurgical slag pot with variable-wall-thickness pot body

A metallurgical slag and variable wall thickness technology, which is applied in the field of metallurgical slag tanks, can solve the problems of unbalanced force, axial buckling, deformation, etc., and achieve the effects of prolonging service life, increasing the critical load of axial buckling, and reducing the cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

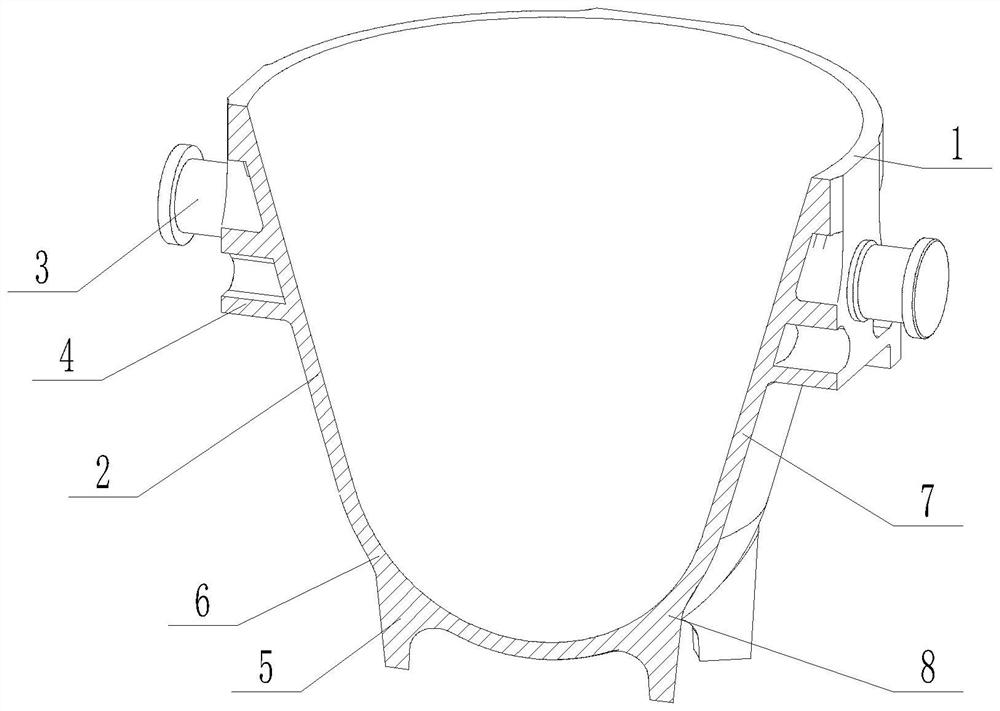

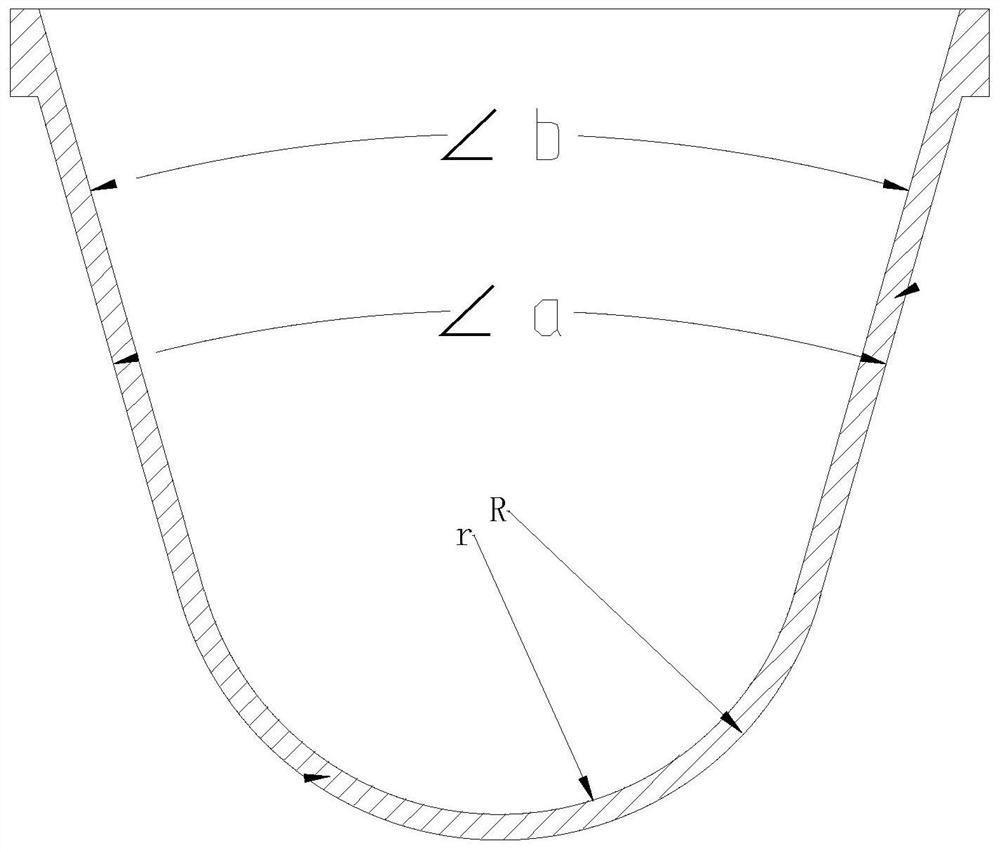

[0025] The invention provides a metallurgical slag tank with a variable wall thickness tank, which is characterized in that it includes a tank mouth flange 1, a tank body 2, a trunnion 3, a trunnion seat 4 and a support base 5, and the tank body 2 is an upper end For an open container with a closed lower end, the tank mouth flange 1 is located at the top opening of the tank body 2, the trunnion seat 4 is located on the outer wall of the upper part of the tank body 2, and the trunnion 3 is fixedly arranged on the trunnion seat 4 Above, the support base 5 is arranged at the bottom of the slag tank, and the tank body 2 is a structure of the tank body 2 that changes the thickness of the tank body 2. The characteristics of the thick and specific slag tank are: the slope angle ∠a<∠b of the outer wall and the inner wall of the tank body 2, the bottom of the tank body 2 includes the tank bottom 6, and the tank bottom 6 is an arc-shaped tank bottom 6, and the tank body 2 The arc-shaped...

Embodiment 2

[0031] The invention provides a metallurgical slag tank with a variable wall thickness tank, which is characterized in that it includes a tank mouth flange 1, a tank body 2, a trunnion 3, a trunnion seat 4 and a support base 5, and the tank body 2 is an upper end For an open container with a closed lower end, the tank mouth flange 1 is located at the top opening of the tank body 2, the trunnion seat 4 is located on the outer wall of the upper part of the tank body 2, and the trunnion 3 is fixedly arranged on the trunnion seat 4 Above, the support base 5 is arranged at the bottom of the slag tank, and the tank body 2 is a structure of the tank body 2 that changes the thickness of the tank body 2. The characteristics of the thick and specific slag tank are: the slope angle ∠a<∠b of the outer wall and the inner wall of the tank body 2, the bottom of the tank body 2 includes the tank bottom 6, and the tank bottom 6 is an arc-shaped tank bottom 6, and the tank body 2 The arc-shaped...

Embodiment 3

[0037] The invention provides a metallurgical slag tank with a variable wall thickness tank, which is characterized in that it includes a tank mouth flange 1, a tank body 2, a trunnion 3, a trunnion seat 4 and a support base 5, and the tank body 2 is an upper end For an open container with a closed lower end, the tank mouth flange 1 is located at the top opening of the tank body 2, the trunnion seat 4 is located on the outer wall of the upper part of the tank body 2, and the trunnion 3 is fixedly arranged on the trunnion seat 4 Above, the support base 5 is arranged at the bottom of the slag tank, and the tank body 2 is a structure of the tank body 2 that changes the thickness of the tank body 2. The characteristics of the thick and specific slag tank are: the slope angle ∠a<∠b of the outer wall and the inner wall of the tank body 2, the bottom of the tank body 2 includes the tank bottom 6, and the tank bottom 6 is an arc-shaped tank bottom 6, and the tank body 2 The arc-shaped...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com