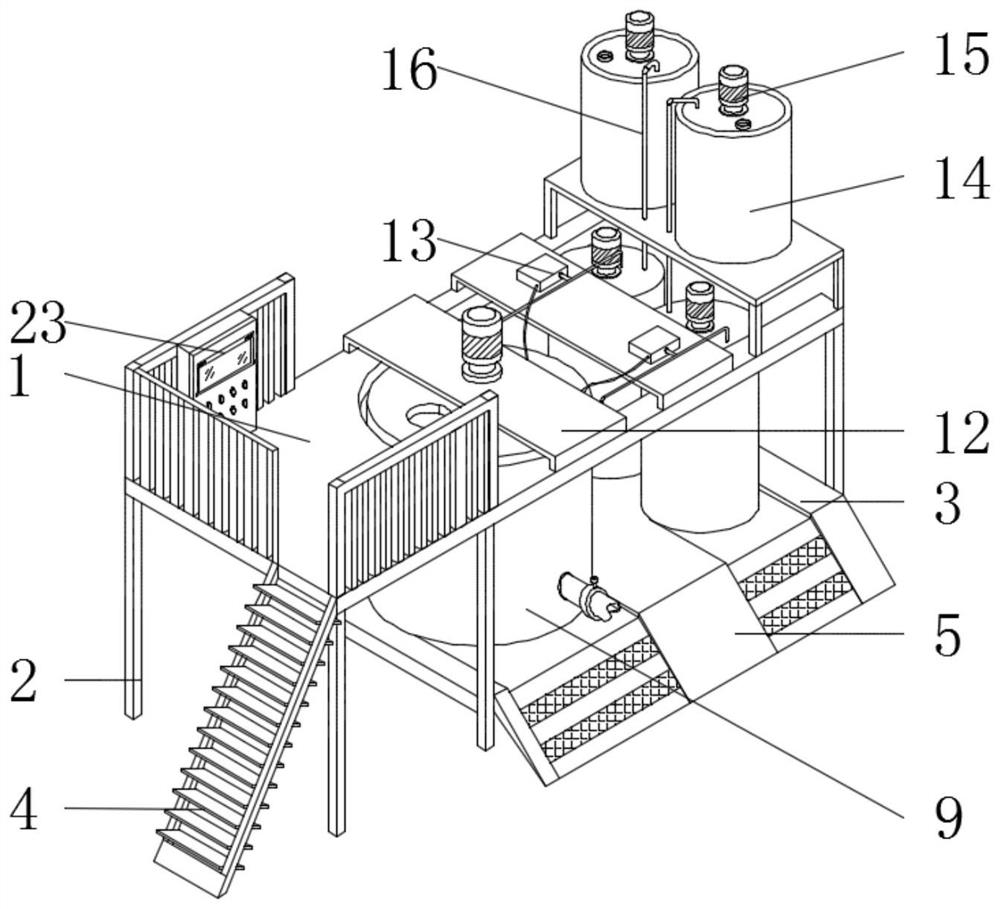

Processing method and processing device of polycarboxylic acid high-performance water reducing agent

A processing method and technology of processing device, which are applied in the direction of feeding device, chemical instrument and method, control/adjustment process, etc., can solve the problems of low and long production efficiency, heating and long processing time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

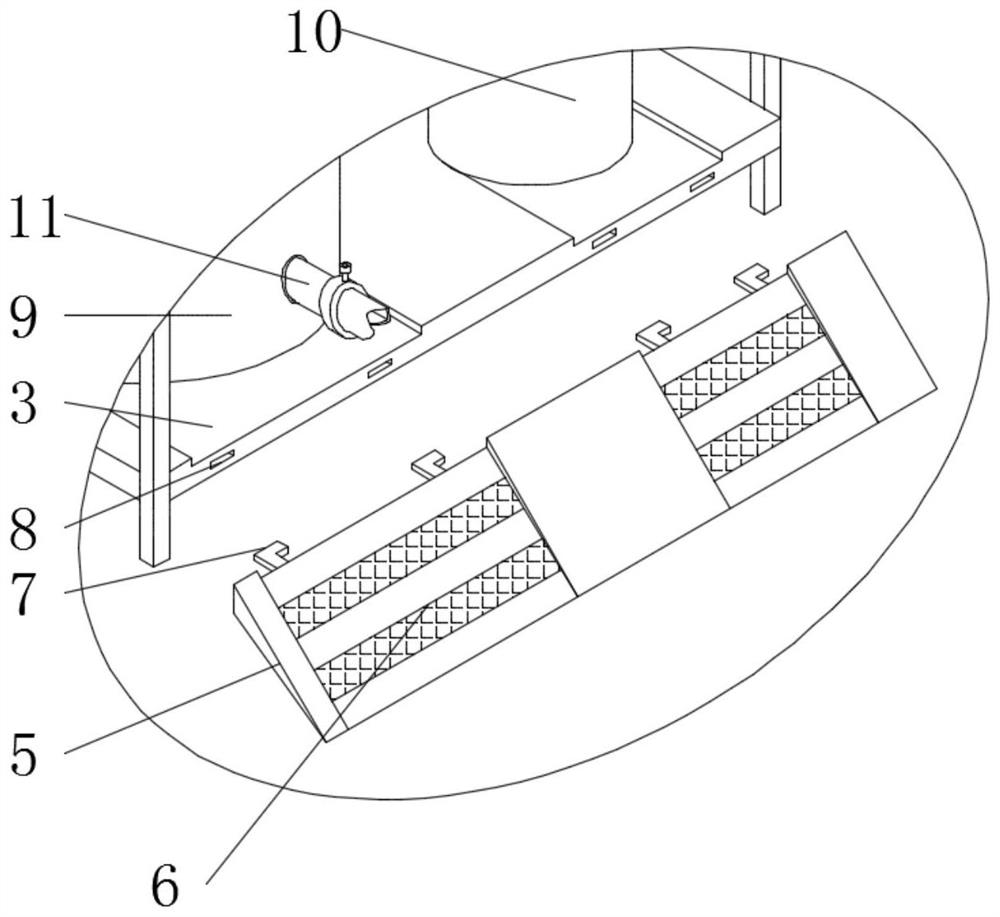

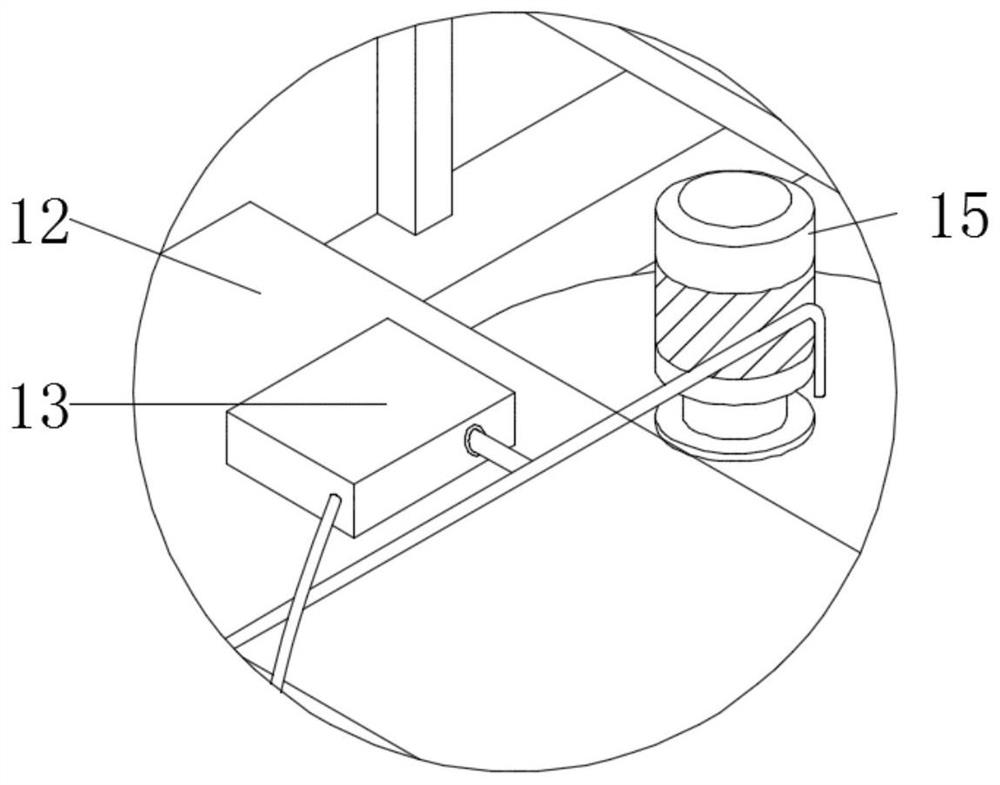

[0034] A processing method of a polycarboxylic acid high-performance water reducer, comprising the following steps: according to the materials required for production, a one-time feeding method is adopted;

[0035] (1) Dissolving material; put deionized water, polyether monomer and hydrogen peroxide into a 10000L stainless steel open reaction kettle for dissolving for 10 minutes until melting;

[0036] (2) Ingredients; for ingredient A, put deionized water and acrylic acid into 2000L metering tank A, stir and dissolve for 10 minutes until completely melted; for ingredient B, put deionized water, mercaptopropionic acid, and VC into 2000L metering tank In B, stir and dissolve for 10 minutes until completely melted;

[0037] (3) Add the prepared material A and material B to the reactor at a constant speed and dropwise for 30 minutes at the same time;

[0038] (4) After adding material A and material B, heat and stir for 30 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com