Automatic feeding and discharging equipment

A technology of equipment and mobile boards, applied in the direction of transportation and packaging, manual conveying devices, etc., can solve the problems of inconvenient roller storage, synchronous and horizontal increase of parking support area, poor support stability, impact, etc., to achieve reasonable design and increase support area , Improve the effect of support stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

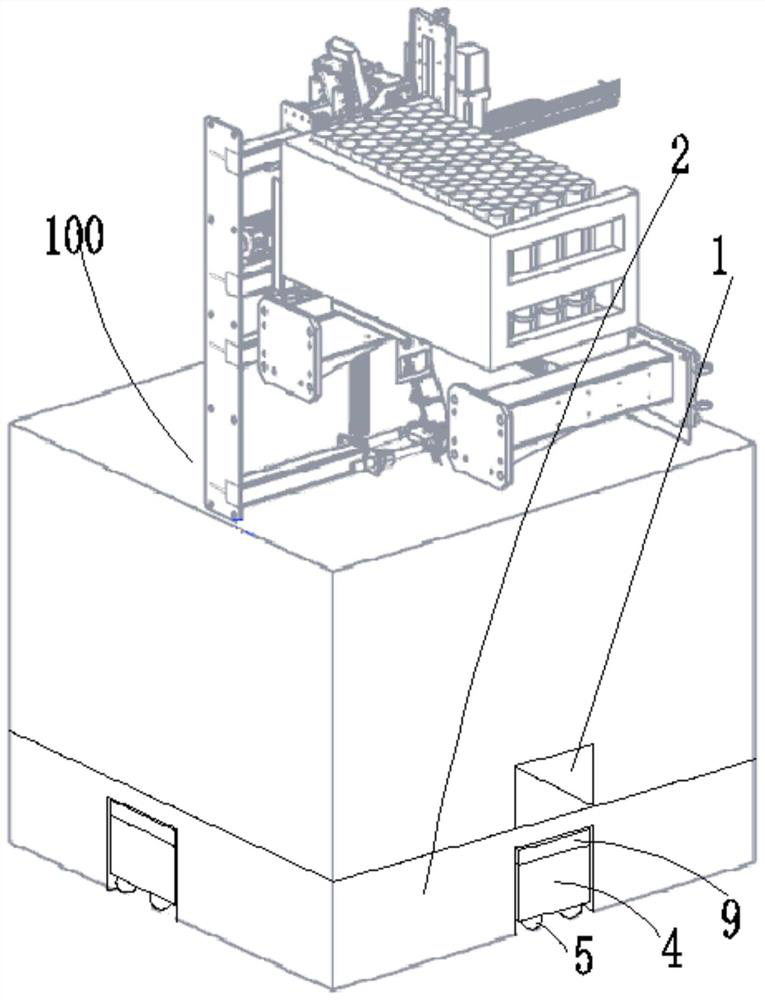

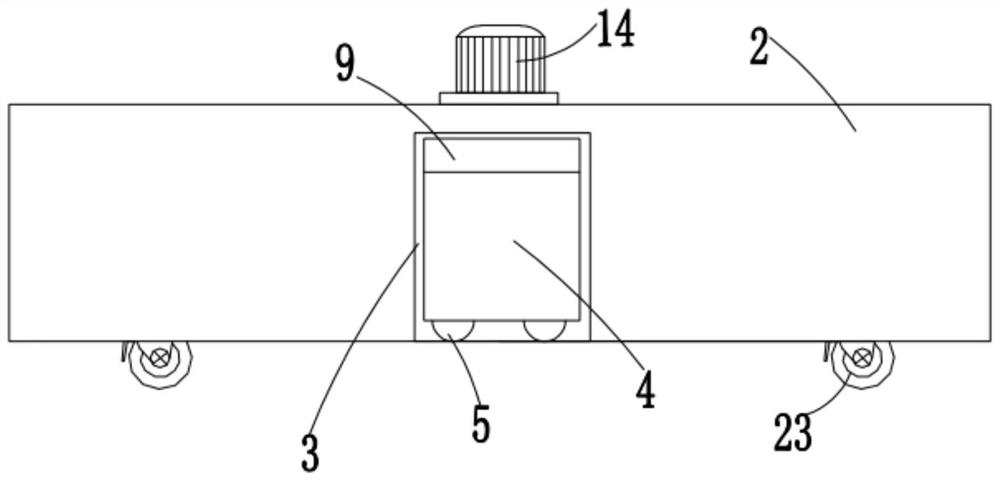

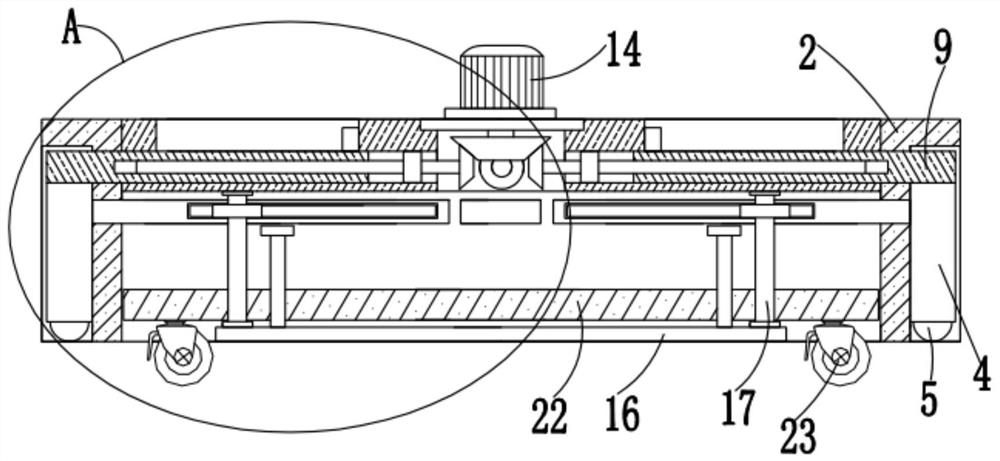

[0027] refer to Figure 1-5 , the present embodiment proposes a kind of automatic loading and unloading equipment, comprises automatic loading and unloading equipment main body 100, the bottom of automatic loading and unloading equipment main body 100 is provided with the groove 1 that front side and rear side are all opening settings, automatic loading and unloading equipment main body The bottom of 100 is provided with an augmented and stable stop type roller storage mechanism, which includes a return-shaped base 2 fixed on the bottom of the main body 100 of the automatic loading and unloading equipment, and the four sides of the return-form base 2 are provided with a bottom A rectangular groove 3 provided for the opening, a support 4 is arranged in the rectangular groove 3, two balls 5 are nested in the bottom of the support 4, the bottom of the balls 5 is flush with the bottom of the return-shaped base 2, and the bottom of the return-form base 2 The same horizontal plate 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com