Shot blasting machine for producing relay valve cover

A technology of shot blasting machine and relay valve, which is applied to the processing device of used abrasives, abrasive jetting machine tools, abrasives, etc., and can solve the problem that the separation of projectiles and sundries cannot be completed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The following is attached Figure 1-4 The application is described in further detail.

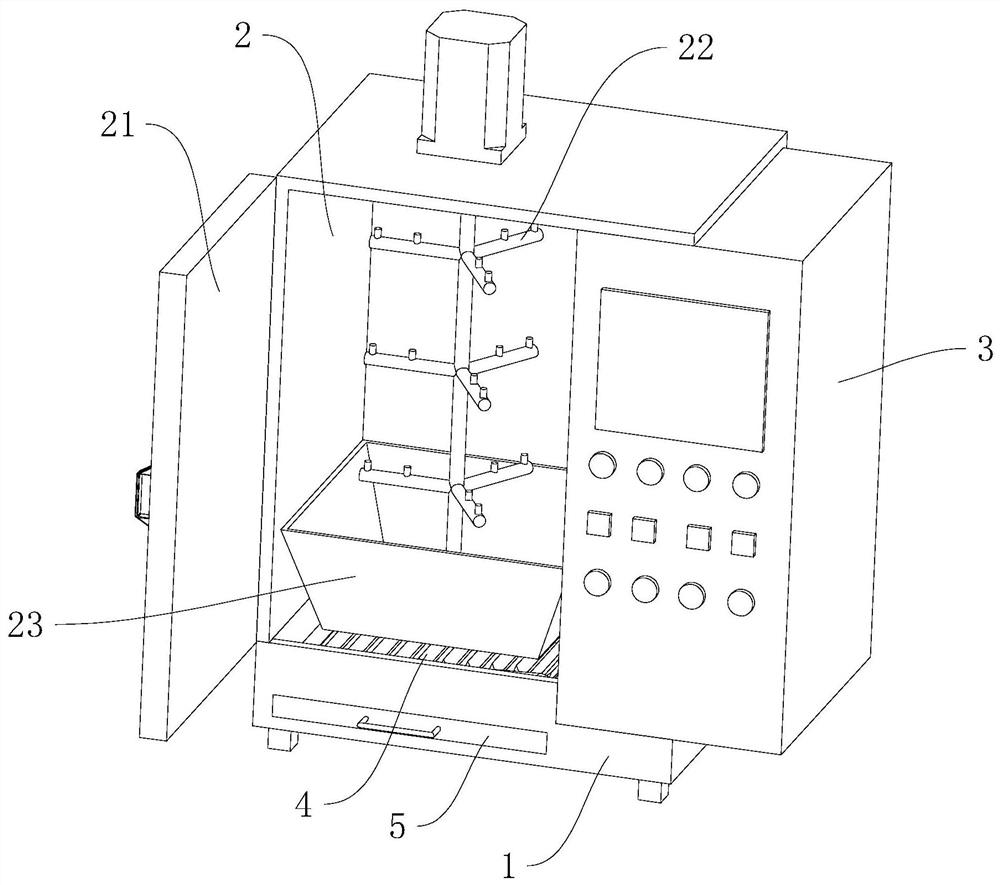

[0038] refer to figure 1 , the embodiment of the present application discloses a shot blasting machine for producing a relay valve cover, including a frame 1 , a shot blasting chamber 2 and a shot blasting device 3 .

[0039] The shot blasting chamber 2 is arranged on the frame 1, and the front of the shot blasting chamber 2 is provided with a door body 21; the shot blasting chamber 2 is provided with a hook 22, and the hook 22 is used for hanging multiple castings. The shot blaster 3 is set on the frame 1, and uses the high-speed rotating impeller to project the projectiles into the shot blasting chamber 2 under the action of high centrifugal force, and project them to the hook 22, so that the projectiles hit the hanging hook 22. casting.

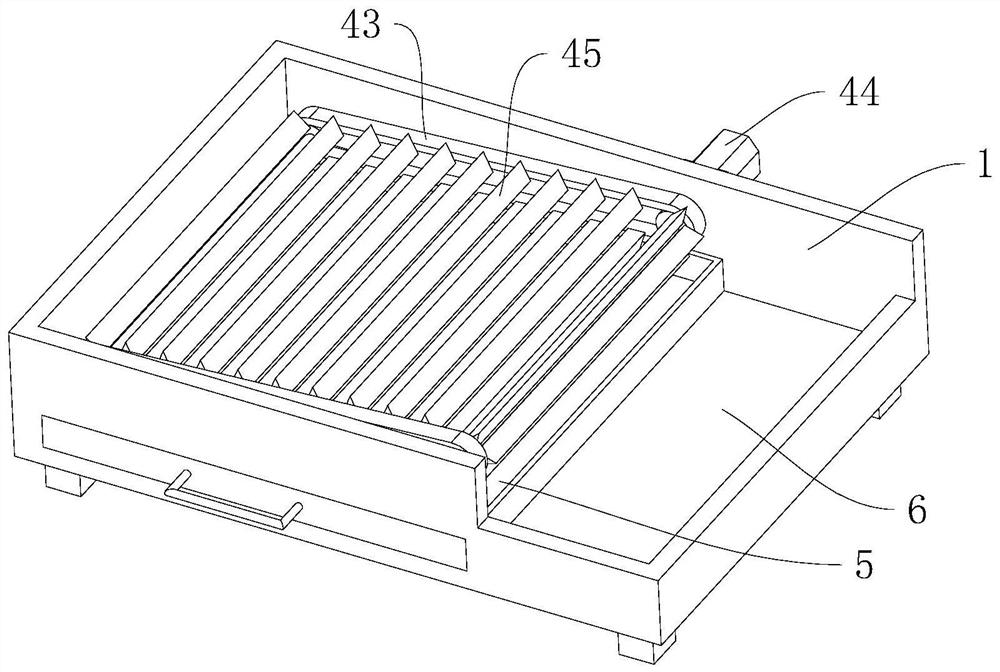

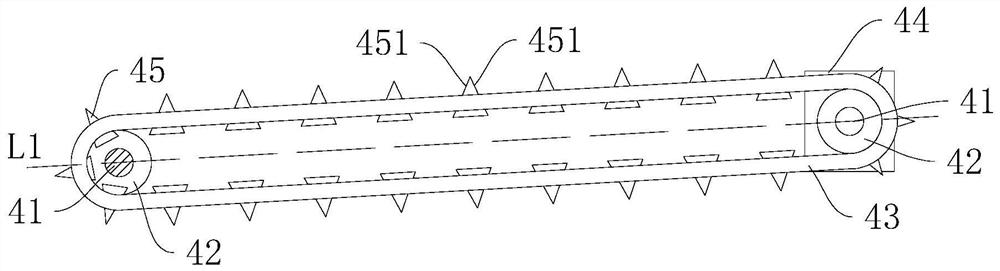

[0040] The bottom of the shot blasting chamber 2 is also provided with a funnel-shaped drop channel 23, and a separation device 4 is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com