Grinding equipment for plate grinding compounding

A technology for grinding and sheet metal, which is applied in the direction of grinding/polishing equipment, parts of grinding machine tools, machine tools suitable for grinding workpiece planes, etc. It can solve the problems affecting the production efficiency of sheet metal, long time consumption, and difficulties in multiple surfaces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

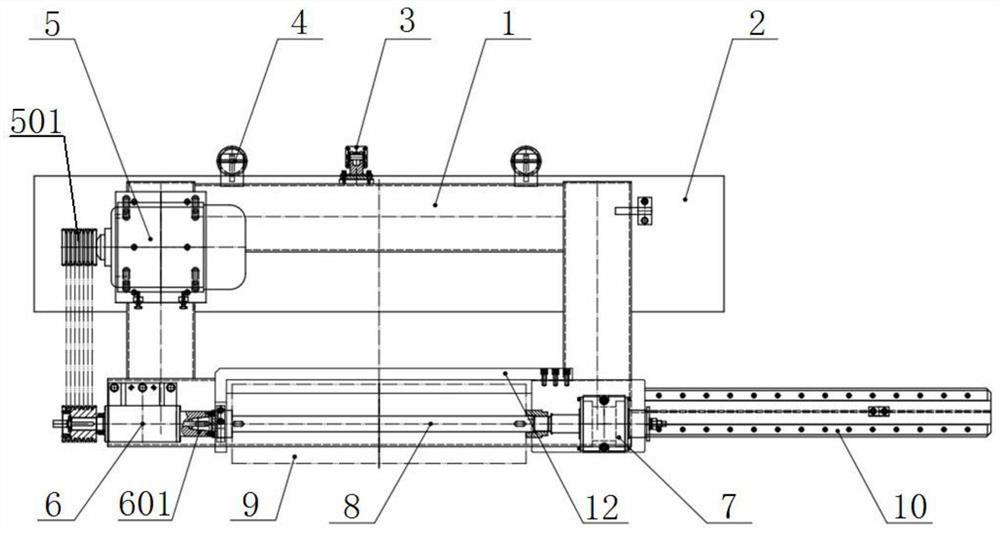

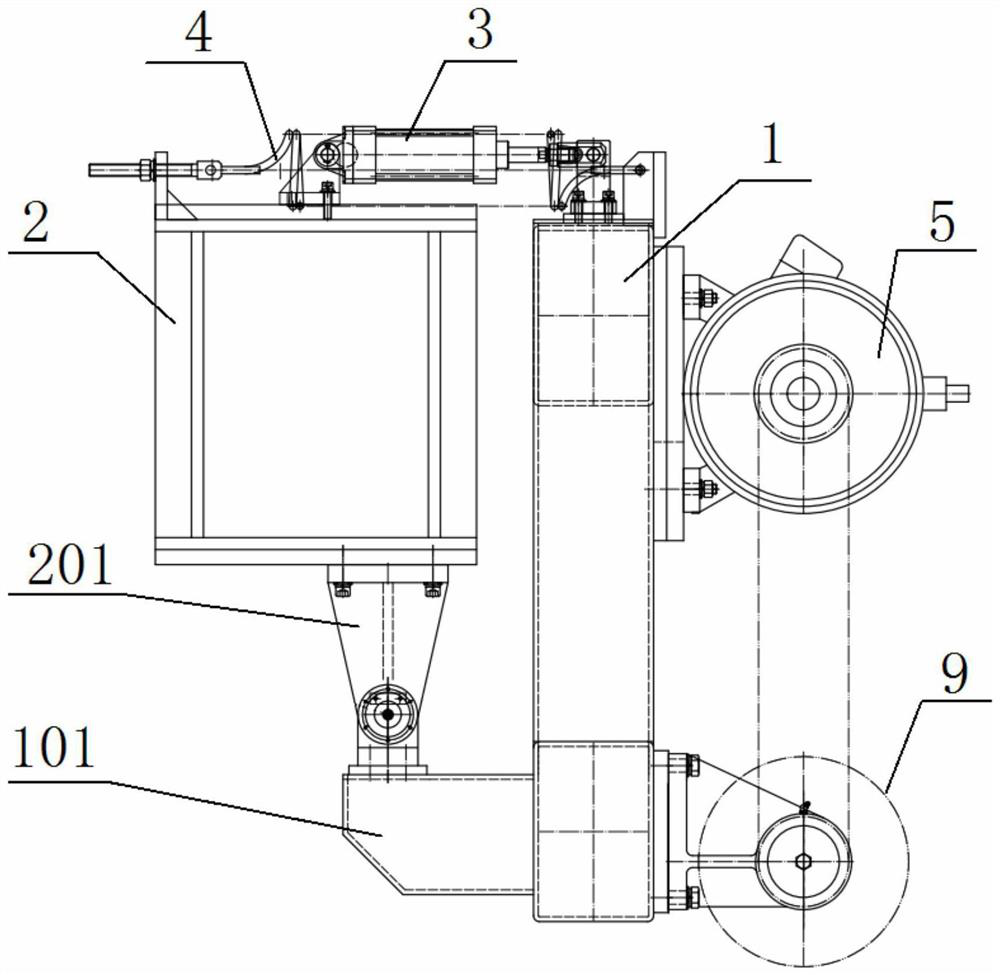

[0042] This embodiment discloses a compound grinding equipment for plate grinding, see figure 1 and figure 2 , including grinding head frame 1, beam 2, cylinder 3, two tension springs 4, drive motor 5, spindle seat mechanism 6, mandrel seat 7, mandrel 8, wire brush roller 9, slide rail assembly 10 and roller changing support Rack 12.

[0043] The grinding head frame 1 is a rectangular frame, and the grinding head frame 1 is vertically arranged, and a hinge shaft I101 protrudes laterally from the lower end thereof.

[0044] The beam 2 is spaced apart from the grinding head frame 1 . A hinge shaft II201 protrudes vertically from the lower end of the beam 2 . The hinge shaft II201 at the lower end of the beam 2 is hinged to the hinge shaft I101 of the grinding head frame 1 .

[0045] The upper end of the cylinder 3 is hinged on the upper end of the crossbeam 2, and the telescopic rod of the cylinder 3 is hinged on the upper end of the grinding head frame 1. Specifically, the...

Embodiment 2

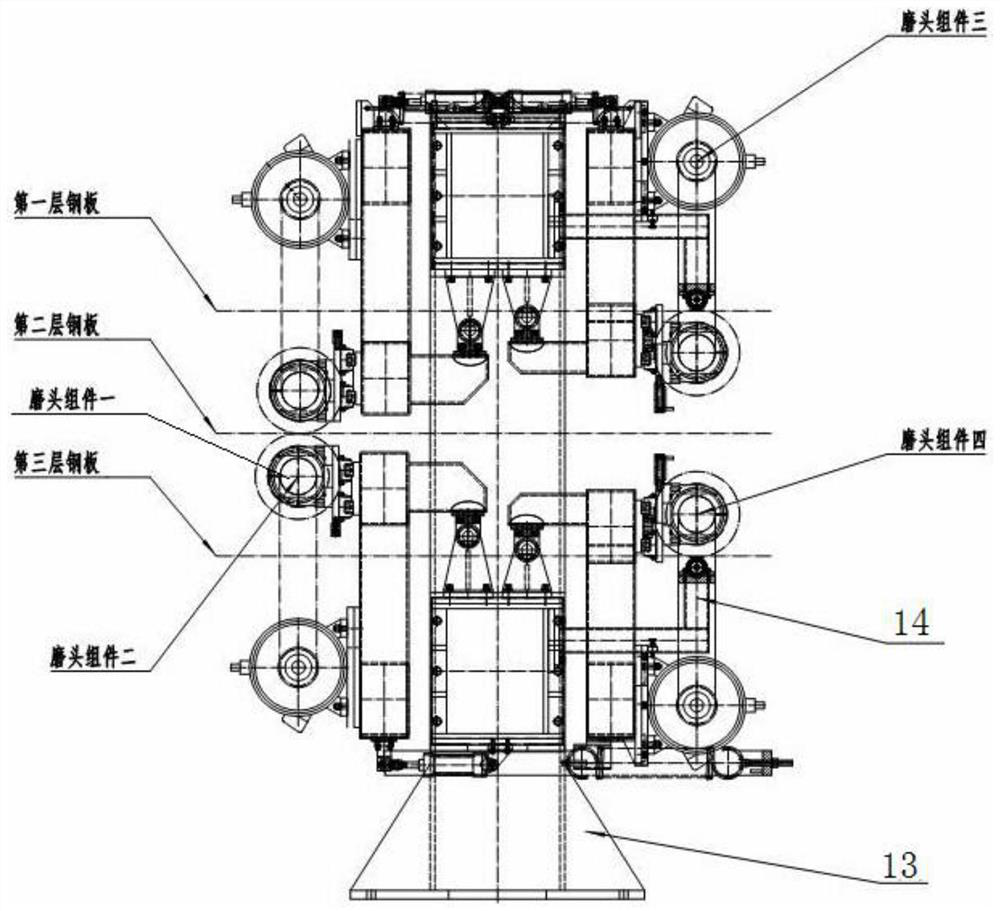

[0062] This embodiment provides a grinding head equipment composed of four grinding heads. In actual use, it is generally necessary to combine four grinding heads to achieve simultaneous rapid grinding of multi-layer plates. The lower ends of the four grinding heads Supported by the frame 13, the production efficiency can be greatly improved. When multiple grinding heads are used in combination, in order to ensure that as many surfaces as possible can be ground at the same time, the following steps can be followed: image 3 Install in the manner shown, the two wire brush rollers in the middle (grinding head assembly 1 and Component 4) needs to install the corresponding support wheel assembly 14; before the equipment starts to work, the three-layer plates need to be placed in an orderly manner as shown in the figure, and then the four grinding heads can be started at the same time, so that To realize the surface treatment of the four surfaces of the three-layer plate; in order...

Embodiment 3

[0064] This embodiment provides a relatively basic implementation method, a kind of plate grinding compound grinding equipment, see figure 1 and figure 2 , including grinding head frame 1, beam 2, cylinder 3, two tension springs 4, drive motor 5, spindle seat mechanism 6, mandrel seat 7, mandrel 8, wire brush roller 9, slide rail assembly 10 and roller changing support Rack 12.

[0065] The grinding head frame 1 is a rectangular frame, and the grinding head frame 1 is vertically arranged, and a hinge shaft I101 protrudes laterally from the lower end thereof.

[0066] The beam 2 is spaced apart from the grinding head frame 1 . A hinge shaft II201 protrudes vertically from the lower end of the beam 2 . The hinge shaft II201 at the lower end of the beam 2 is hinged to the hinge shaft I101 of the grinding head frame 1 .

[0067] The upper end of the cylinder 3 is hinged on the upper end of the crossbeam 2, and the telescopic rod of the cylinder 3 is hinged on the upper end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com