Hobbing clamp with self-adjustable clamping force for gear hobbing machine tool

A gear hobbing fixture and clamping force technology, applied in the field of gear hobbing, can solve the problems of unstable clamping, difficult to guarantee gear hobbing processing accuracy, affecting the quality of gear hobbing processing, etc., to achieve the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

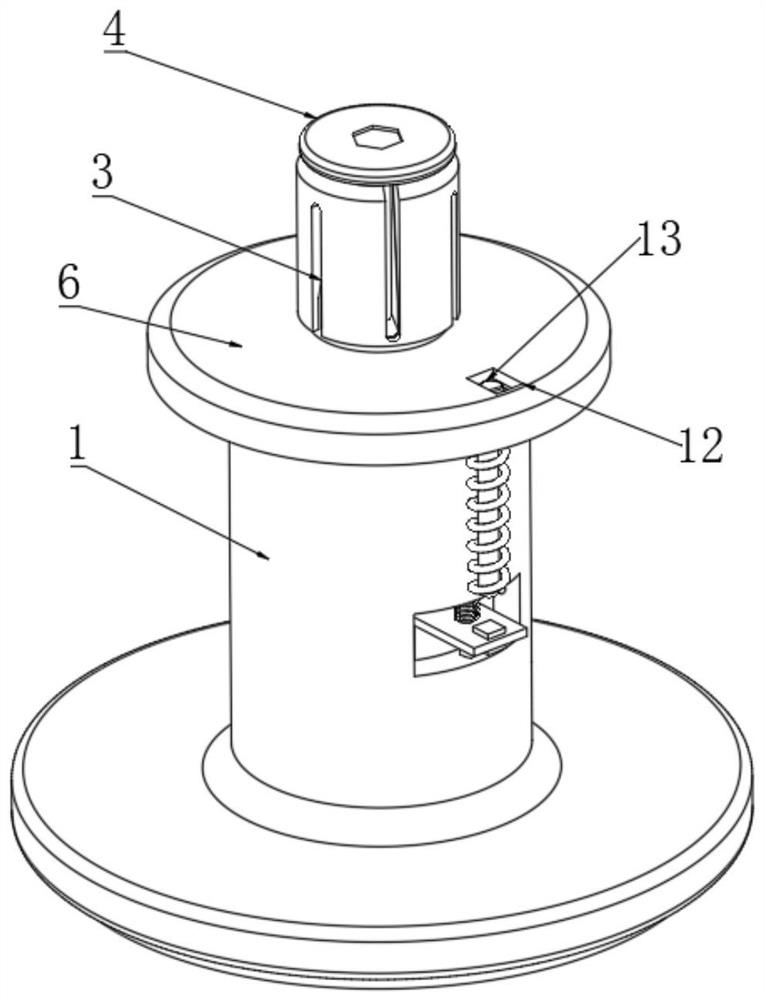

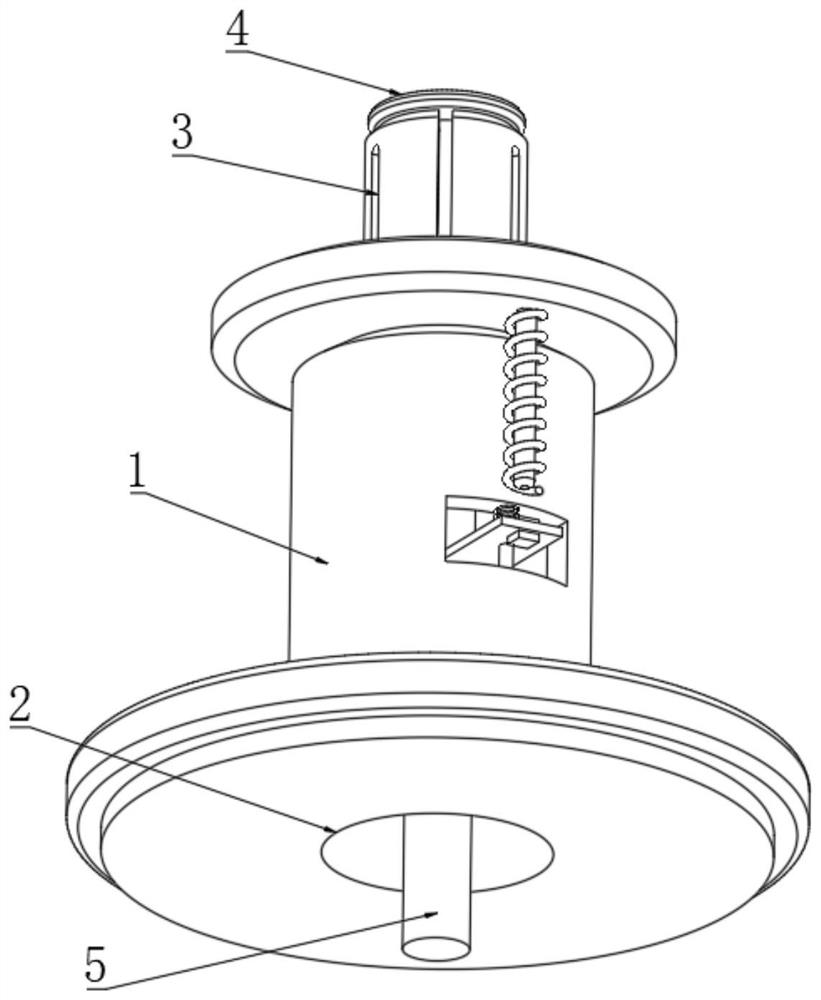

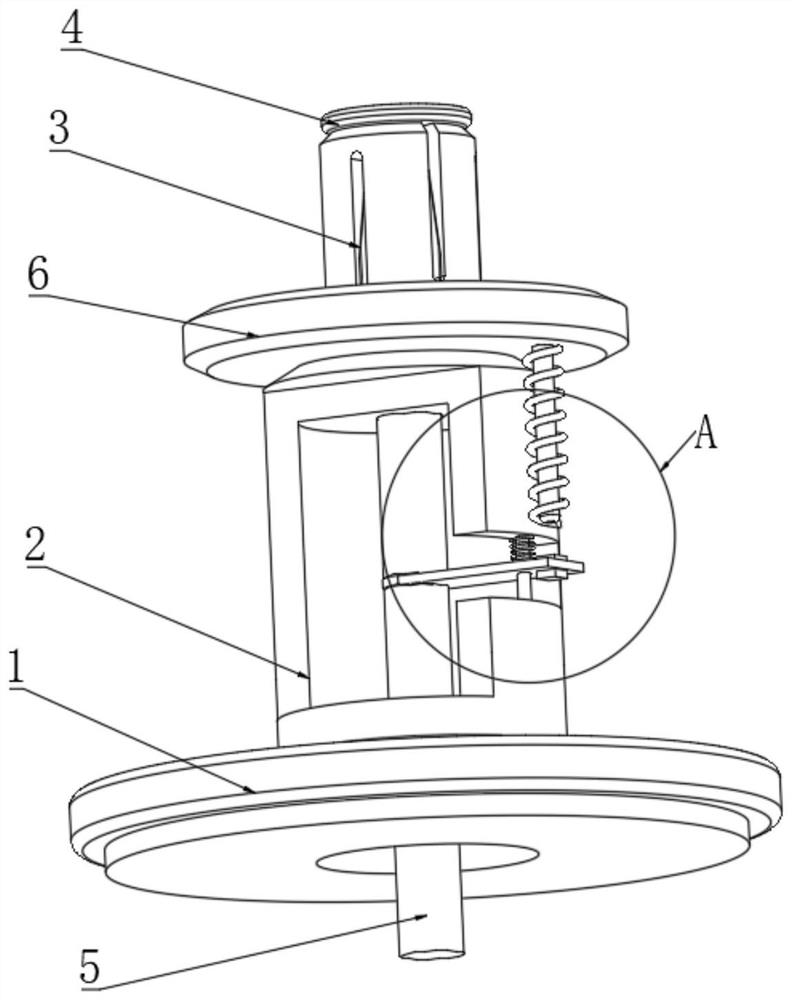

[0024] refer to Figure 1-4 , a gear hobbing fixture with self-adjusting clamping force for gear hobbing machine tools, comprising a fixture body 1, a round hole 2 is opened on the fixture body 1, an expansion sleeve 3 is set on the clamp body 1, and a mounting bracket is placed on the top of the expansion sleeve 3 Plate 4, the bottom side wall of the mounting plate 4 penetrates to the inside of the round hole 2 and is fixedly connected with a tie rod 5, a positioning plate 6 is arranged on the fixture body 1, a square groove 7 is opened on the fixture body 1, and the square groove 7 passes through a guide The device is slidably connected with a transmission plate 8, the guide device is composed of a fixed rod 14 and a spring 15, the fixed rod 14 is fixed on the opposite side wall of the square groove 7, the transmission plate 8 is slidably connected with the side wall of the fixed rod 14, and the spring 15 is sleeved On the side wall of the fixed rod 14, one end of the spring...

Embodiment 2

[0030] A protective plate 16 is installed on the inner wall of the installation groove 12 .

[0031] The material of the protective plate 16 is ceramics.

[0032] refer to Figure 5 , the difference from Embodiment 1 is that: the thermistor 13 on the installation groove 12 is protected by the protective plate 16, so as to avoid damage to the thermistor 13 during the processing of the teeth, and the setting of the ceramic material , while insulating, the efficiency of heat conduction is increased, and the sensitivity of clamping force self-regulation is further increased.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com