Efficient plate cutting machine for construction site

A construction site and cutting machine technology, applied in the direction of shearing devices, manufacturing tools, metal processing equipment, etc., can solve the problems of plate shape and size deviation, cutting equipment inefficiency, and inability to control plate size, etc., to achieve fast and effective cutting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

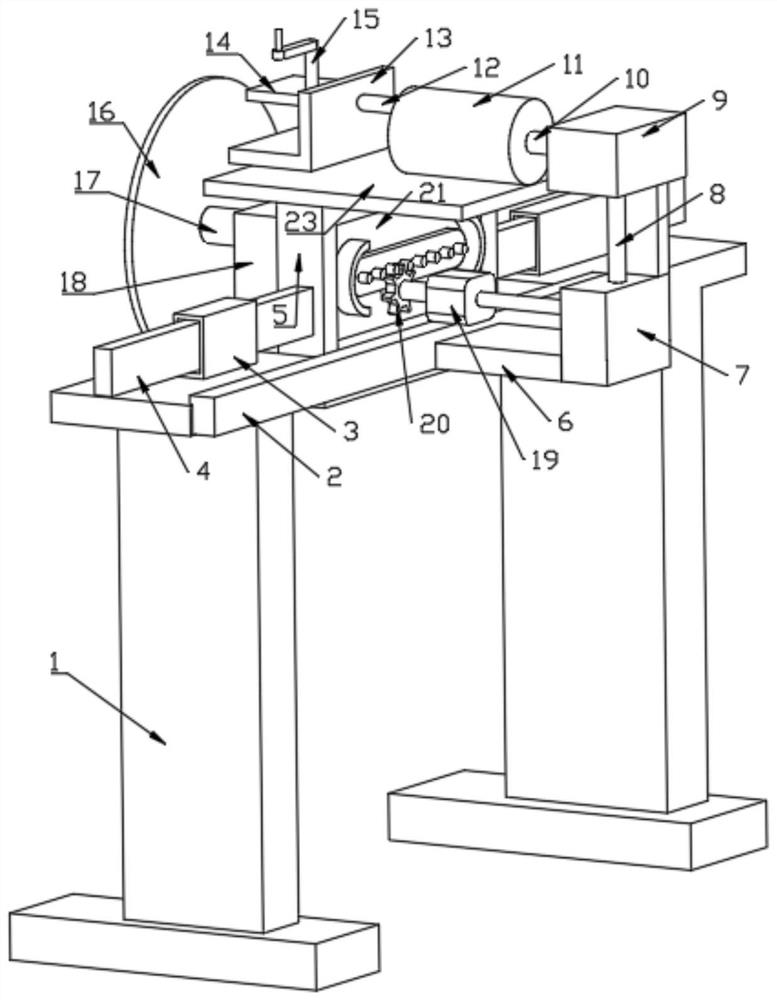

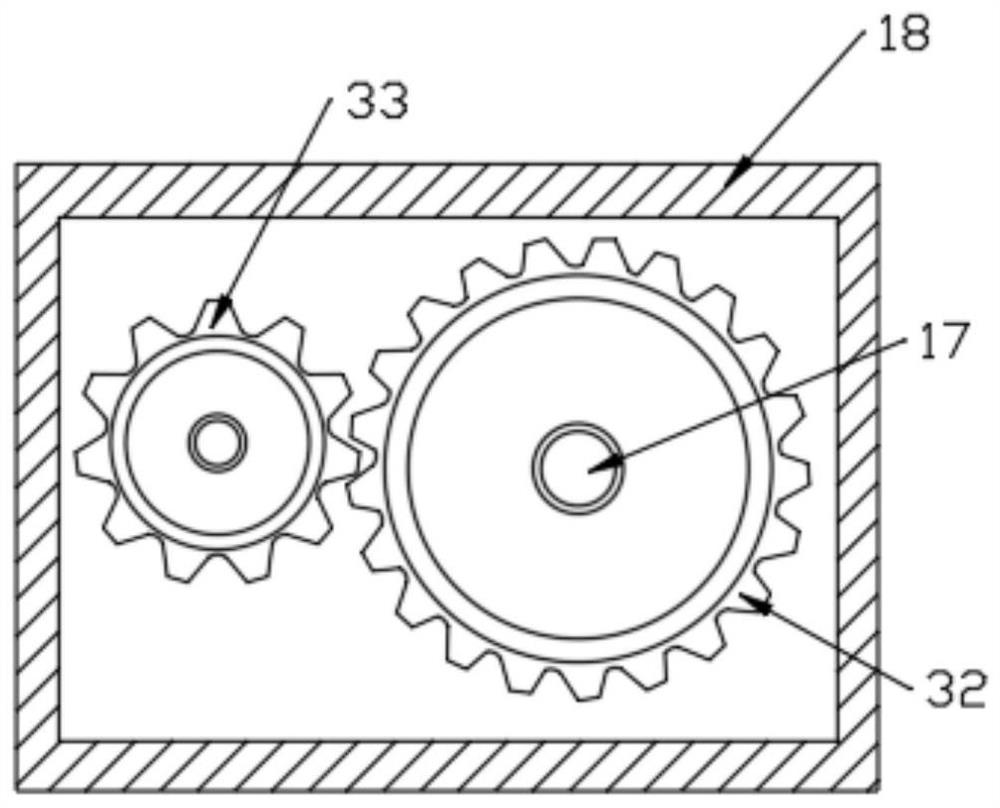

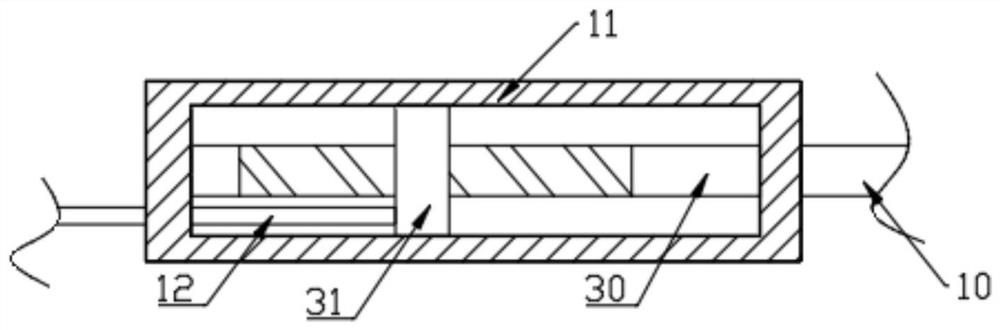

[0025] refer to Figure 1-6 , a high-efficiency plate cutting machine for construction sites, including two support platforms 1 of the cutting machine, a support rod 2 is fixedly connected between the two support platforms 1, and a biaxial motor 19 is fixedly connected to the upper end of the support rod 2, and two support The upper ends of the platform 1 are respectively fixedly connected with guide sleeves 3, and a support frame 5 is arranged between the two support platforms 1, and both sides of the support frame 5 are fixedly connected with guide rods 4 respectively penetrating through the two guide sleeves 3, and the two guide rods 4 Slide in the two guide sleeves 3, and then the cutting platform 23 above can be reciprocated stably, making the cutting process more stable. The support frame 5 is equipped with a reciprocating mechanism that can make ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com