Hydrogen fuel cell film electrode assembly suitable for batch production and production process thereof

A fuel cell membrane and electrode assembly technology, which is applied in the direction of fuel cells, battery electrodes, electrical components, etc., and can solve problems such as poor consistency and inability to mass produce

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

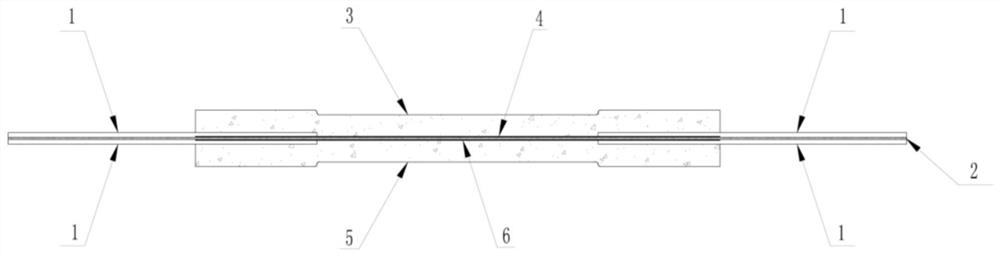

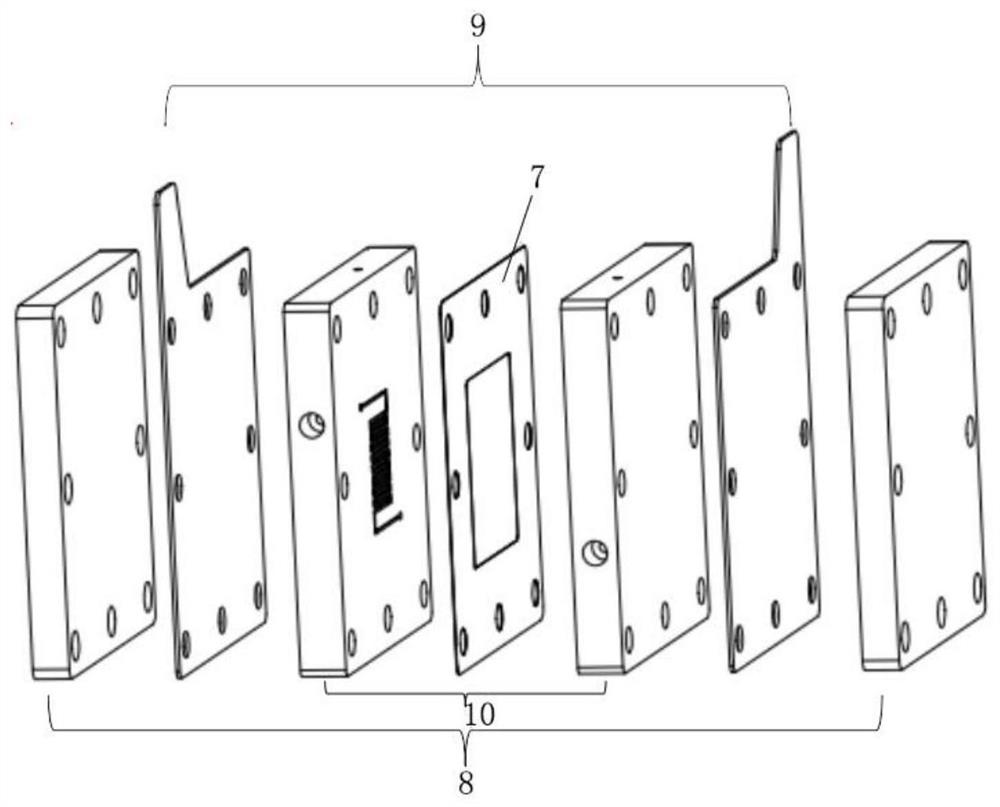

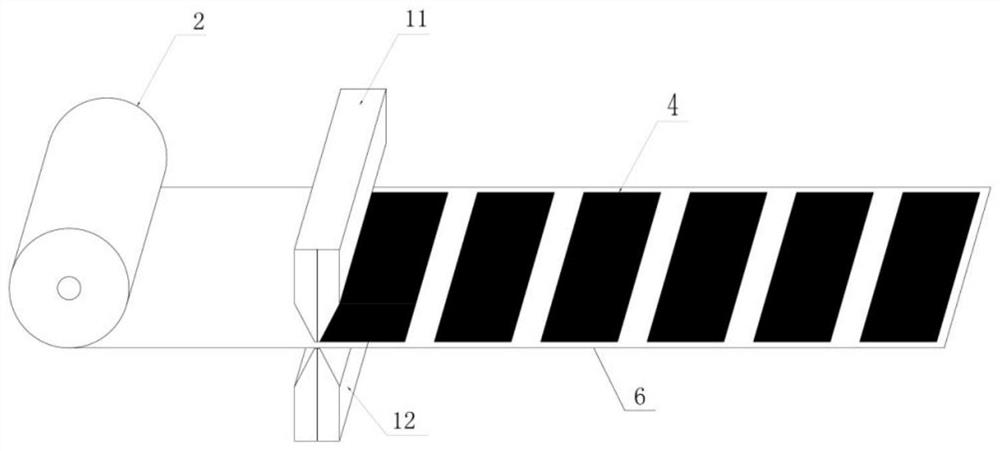

[0042] Such as figure 1 As shown, the present invention provides a hydrogen fuel cell membrane electrode assembly suitable for mass production, including a gas diffusion layer, a catalytic layer and a perfluorosulfonic acid resin membrane 2, and also includes a protective film frame 1; the perfluorosulfonic acid Each side of the acid resin film 2 is uniformly coated with one layer of the catalytic layer, bonded with one layer of the protective film frame and one layer of the gas diffusion layer;

[0043] In this embodiment, the catalytic layer includes an anode catalytic layer 4 and a cathode catalytic layer 6, and the gas diffusion layer includes an anode gas diffusion layer 3 and a cathode gas diffusion layer 5;

[0044] The inner edge of the protective film frame 1 is 1-2mm closer to the center of the perfluorosulfonic acid resin film 2 than the outer edge of the gas diffusion layer; Sulfonic acid resin membrane 2; the gas diffusion layer is bonded to the protective film f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com