Gas-electric series-parallel ship hybrid power test bed with energy management system and control method of gas-electric series-parallel ship hybrid power test bed

An energy management system, gas-electric hybrid technology, applied in the direction of electrical testing/monitoring, general control system, control/regulation system, etc., can solve the problem of speed, acceleration and self-control, power grid diesel generator set that cannot achieve high performance Fixed-speed power generation efficiency is low, high manufacturing costs and other issues, to achieve the effect of wide power coverage, high energy transfer efficiency, and compact layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

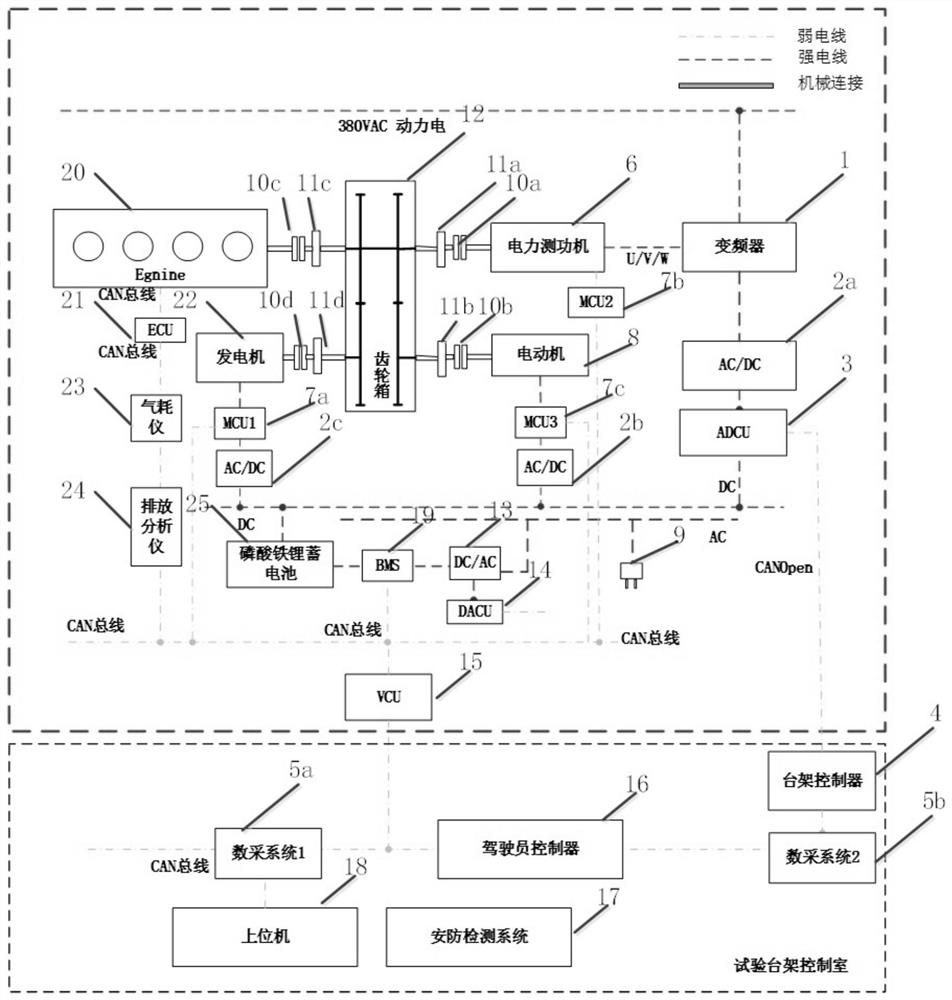

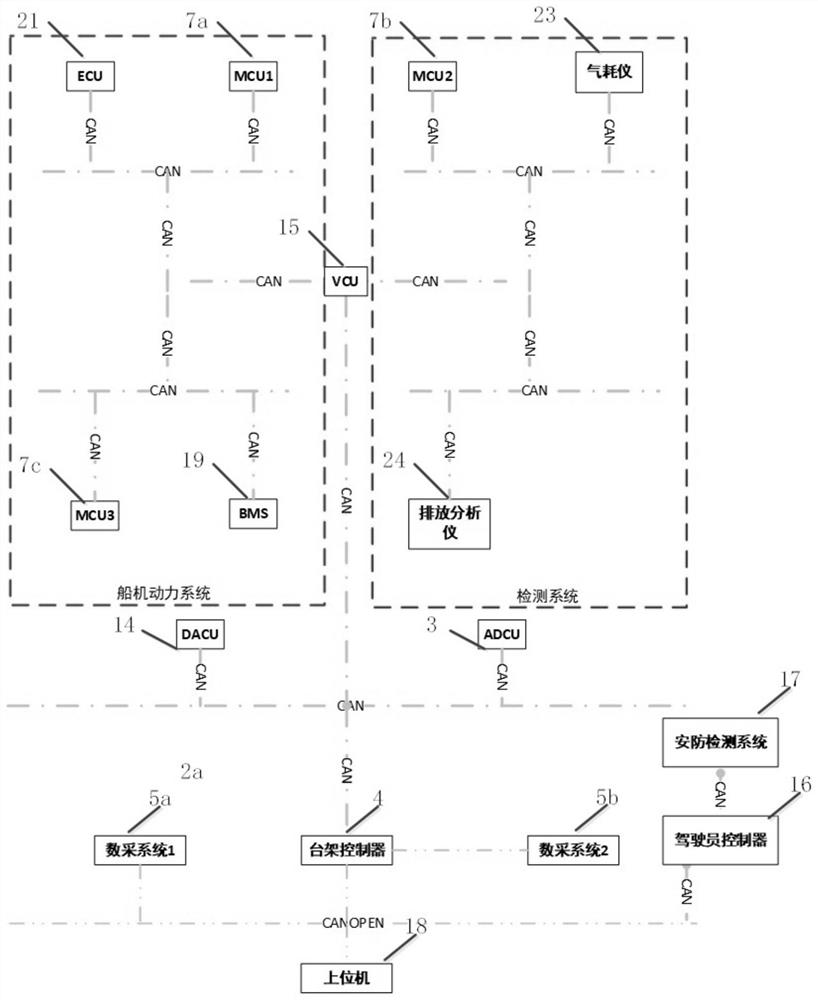

[0035] The present invention is described in more detail below in conjunction with accompanying drawing example:

[0036] combine Figure 1-3 , a gas-electric hybrid ship hybrid test bench with an energy management system of the present invention, including a frequency converter 1, rectification devices 2a, 2b, 2c, rectification device controller 3, bench controller 4, and data acquisition system 5a , 5b, electric dynamometer 6, generator controller 7a, electric dynamometer controller 7b, motor controller 7c, electric motor 8, external power supply 9, clutch 10a, 10b, 10c, 10d, torque flange 11a, 11b . , gas machine controller 21, generator 22, gas consumption meter 23, emission analyzer 24, storage battery 25. The connection relationship is as follows: the gas machine 20 is axially connected to the gearbox 12 through the clutch 10c and the torque flange 11c, and then drives the electric dynamometer 6 through the torque flange 11a and the clutch 10a. The electric motor 8 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com