Brightness enhancement film with high resilience and high brightness

A brightness-enhancing film and high-resilience technology, which is applied in optics, instruments, nonlinear optics, etc., can solve the problems of complex processing technology and low brightness of the brightness-enhancing film backlight module

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

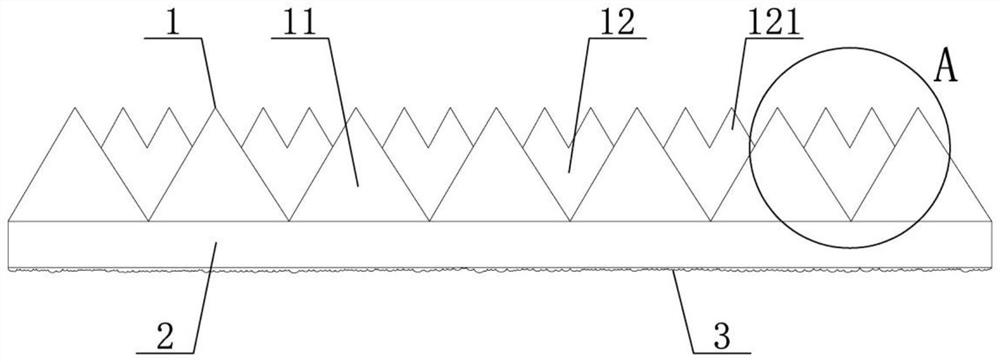

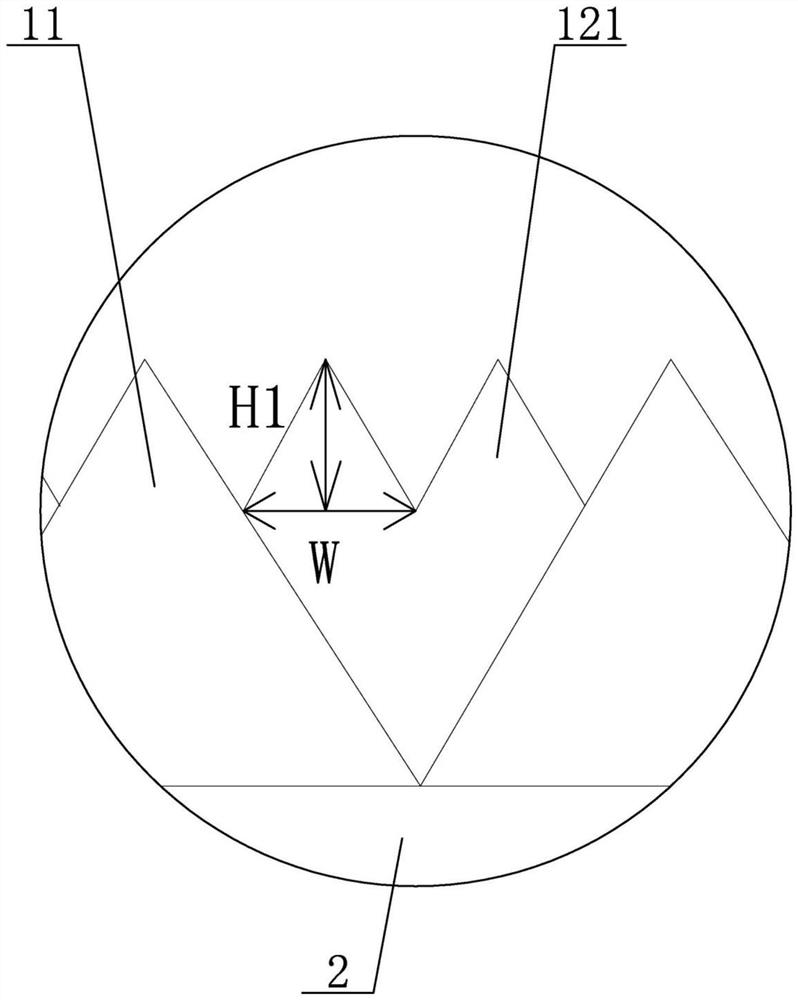

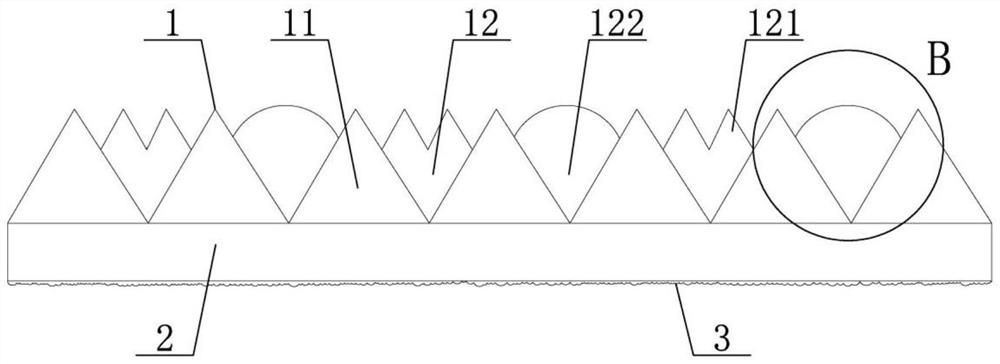

[0032] A high-resilience and high-brightness brightness-enhancing film, comprising a prism layer 1, a substrate layer 2, and a back coating structure layer 3 arranged in sequence, the prism layer 1 comprising a first prism structure 11 and a second prism structure 12 The cross-section of the prisms of the first prism structure 11 is triangular, the prisms of the second prism structure 12 are evenly arranged between the prisms of the first prism structure 11, each of the second prism structures 12 The upper part of the prism is provided with two upper corners 121, the highest point of the first prism structure 11 is flush with the highest point of the upper corners 121, and its preparation method is as follows:

[0033] S1: Take a polyester film with a thickness of 188 μm as the substrate layer 2, and make a back-coated structural layer 3 on the lower surface of the polyester film;

[0034] S2: Take the copper-plated stainless steel roll blank A, engrave it with an ultra-precis...

Embodiment 2

[0046] A high-resilience and high-brightness brightness-enhancing film, comprising a prism layer 1, a substrate layer 2, and a back coating structure layer 3 arranged in sequence, the prism layer 1 comprising a first prism structure 11 and a second prism structure 12 The cross-section of the prisms of the first prism structure 11 is triangular, the prisms of the second prism structure 12 are evenly arranged between the prisms of the first prism structure 11, each of the second prism structures 12 The upper part of the prism is provided with two upper corners 121, the highest point of the first prism structure 11 is flush with the highest point of the upper corners 121, and its preparation method is as follows:

[0047] S1: Take a polyester film with a thickness of 250 μm as the substrate layer 2, and make a back-coated structural layer 3 on the lower surface of the polyester film;

[0048] S2: Take the copper-plated stainless steel roll blank A, engrave it with an ultra-precis...

Embodiment 3

[0060] A high-resilience and high-brightness brightness-enhancing film, comprising a prism layer 1, a substrate layer 2, and a back coating structure layer 3 arranged in sequence, the prism layer 1 comprising a first prism structure 11 and a second prism structure 12 The cross-section of the prisms of the first prism structure 11 is triangular, the prisms of the second prism structure 12 are evenly arranged between the prisms of the first prism structure 11, each of the second prism structures 12 The upper part of the prism is provided with two upper corners 121, the highest point of the first prism structure 11 is flush with the highest point of the upper corners 121, and its preparation method is as follows:

[0061] S1: Take a polyester film with a thickness of 219 μm as the substrate layer 2, and make a back-coated structural layer 3 on the lower surface of the polyester film;

[0062] S2: Take the copper-plated stainless steel roll blank A, engrave it with an ultra-precis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bottom width | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com