Processing and detection method for improving floating sleeve inner hole oil wedge detection efficiency

A technology of detection efficiency and detection method, applied in measurement devices, mechanical measurement devices, mechanical depth measurement, etc., can solve the problems of difficult to guarantee the oil wedge lift accuracy, difficult processing and detection, loss of base circle reference point, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

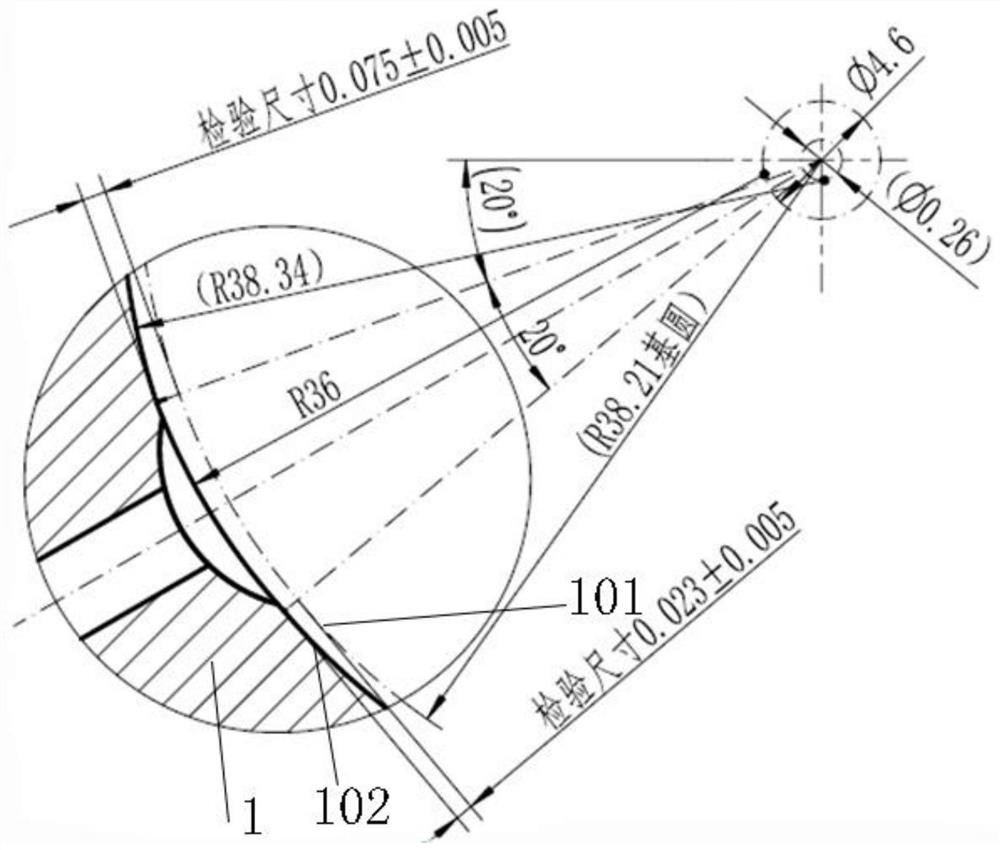

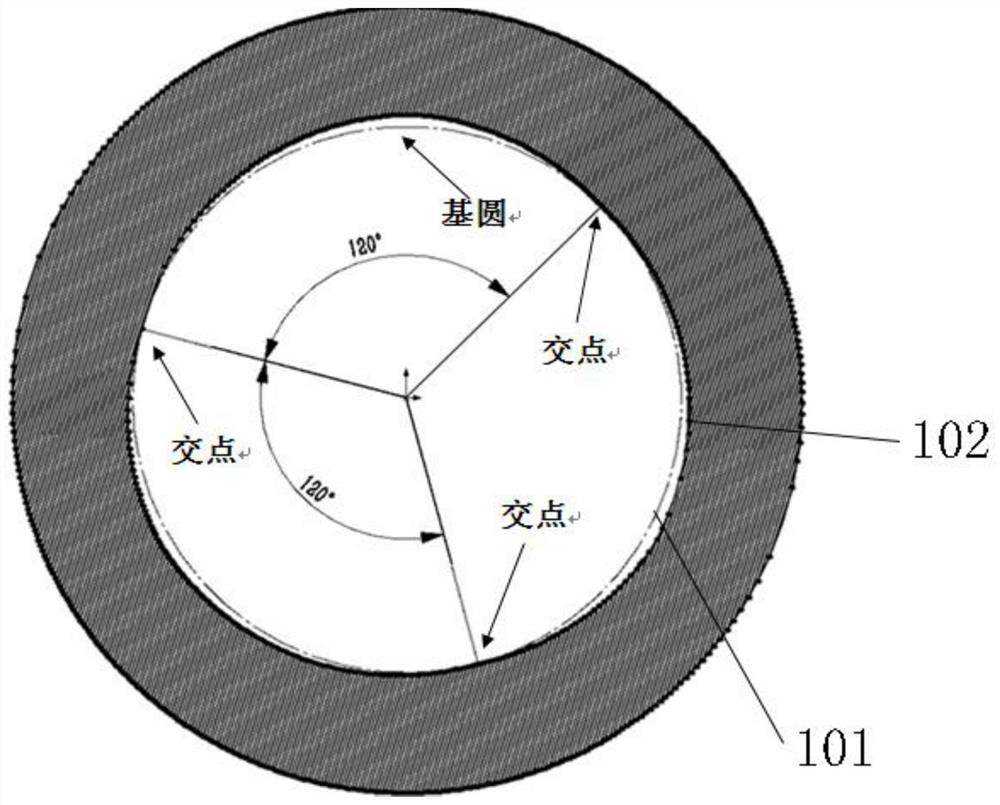

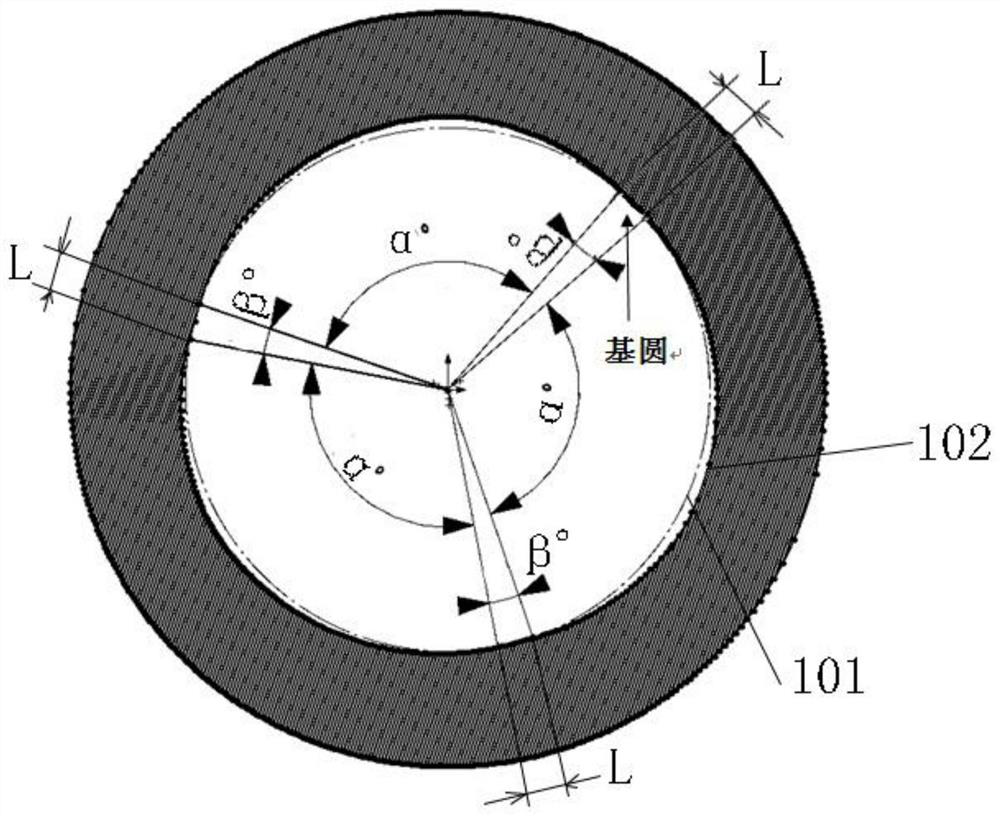

[0038] Design principle of the present invention:

[0039] Through the in-depth analysis of the part structure, it is found that the floating sleeve parts are evenly distributed oil wedges in a certain angle area near the intersection of the base circle, and the theoretical lift value of the oil wedge arc and the base circle is very small. image 3 The lift value at the starting point of the single-fan oil wedge with an included angle of α is only 0.001mm. Whether this value is processed or not has basically no effect on the performance of the oil wedge structure of the part, so it can be seen from this point This kind of processing structure change itself is feasible.

[0040] The invention deeply analyzes the function of the oil wedge itself and the degree of influence of changing the lift on product performance, and realizes the double efficiency of processing and testing by changing the arc processing structure of the oil wedge itself. The changed oil wedge circle Arc pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com