Novel yin-yang composite flexible polymer microsphere and preparation method thereof

A flexible polymer and polymer technology, applied in drilling compositions, chemical instruments and methods, etc., can solve the problems of insufficient depth profile control ability and controllability of polymer microspheres, and achieve temperature resistance and salt resistance. Good, high utilization, improve the effect of agglomeration and adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

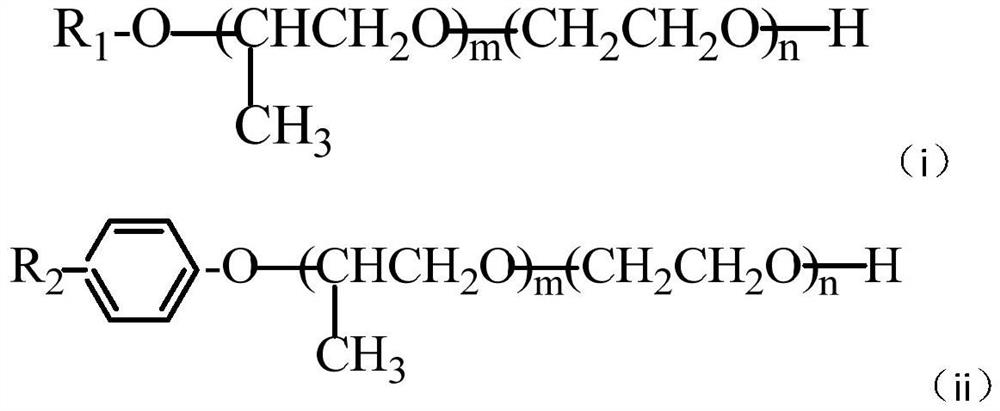

Method used

Image

Examples

Embodiment 1

[0063] Dissolve 25 parts of acrylamide, 0.5 parts of disodium edetate, 1 part of tert-butylacrylamide, and 0.2 parts of methylenebisacrylamide in 30 parts of deionized water to prepare a solution, and adjust the pH value to 6-10 between. Dissolve 0.0125 parts of azobisisobutyl ether hydrochloride in 1 part of deionized water to form an aqueous solution, then add it to the above monomer solution and stir evenly.

[0064] Dissolve 6 parts of sorbitan oleate and 4 parts of fatty alcohol polyoxyethylene ether in 50 parts of 5# white oil, configure an oil solution, add it to the reaction kettle, and stir at a rate of 200r / min. The above aqueous solution was slowly added into the reaction kettle under stirring, and the stirring was continued for 30 minutes. The temperature in the kettle was controlled by a water bath to 20° C., and nitrogen gas was used to remove oxygen.

[0065] Stirring was continued, the temperature was raised in a water bath at a rate of 200 r / min until the tem...

Embodiment 2

[0069] Dissolve 25 parts of acrylamide, 0.5 parts of disodium edetate, 1 part of tert-butylacrylamide, and 0.2 parts of methylenebisacrylamide in 30 parts of deionized water to prepare a solution, and adjust the pH value to 6-10 between. Dissolve 0.0125 parts of azobisisobutyl ether hydrochloride in 1 part of deionized water to form an aqueous solution, then add it to the above monomer solution and stir evenly.

[0070] Dissolve 6 parts of sorbitan oleate and 4 parts of fatty alcohol polyoxyethylene ether in 50 parts of 5# white oil, configure an oil solution, add it to the reaction kettle, and stir at a rate of 200r / min. The above aqueous solution was slowly added into the reaction kettle under stirring, and the stirring was continued for 30 minutes. The temperature in the kettle was controlled by a water bath to 20° C., and nitrogen gas was used to remove oxygen.

[0071] Stirring was continued, the temperature was raised in a water bath at a rate of 200 r / min until the tem...

Embodiment 3

[0075] Dissolve 25 parts of acrylamide, 0.5 parts of disodium edetate, 1 part of tert-butylacrylamide, and 0.2 parts of methylenebisacrylamide in 30 parts of deionized water to prepare a solution, and adjust the pH value to 6-10 between. Dissolve 0.0125 parts of azobisisobutyl ether hydrochloride in 1 part of deionized water to form an aqueous solution, then add it to the above monomer solution and stir evenly.

[0076] Dissolve 6 parts of sorbitan oleate and 4 parts of fatty alcohol polyoxyethylene ether in 50 parts of 5# white oil, configure an oil solution, add it to the reaction kettle, and stir at a rate of 200r / min. The above aqueous solution was slowly added into the reaction kettle under stirring, and the stirring was continued for 30 minutes. The temperature in the kettle was controlled by a water bath to 20° C., and nitrogen gas was used to remove oxygen.

[0077] Stirring was continued, the temperature was raised in a water bath at a rate of 200 r / min until the tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com