Long-distance building concrete taking device

A reclaiming device and concrete technology, which is applied to clay preparation devices, cement mixing devices, transportation and packaging, etc., can solve the problems of long-distance retrieving concrete that is easy to solidify, labor is large, and affects quality, so as to achieve high construction efficiency and reduce Labor force, the effect of ensuring the quality of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

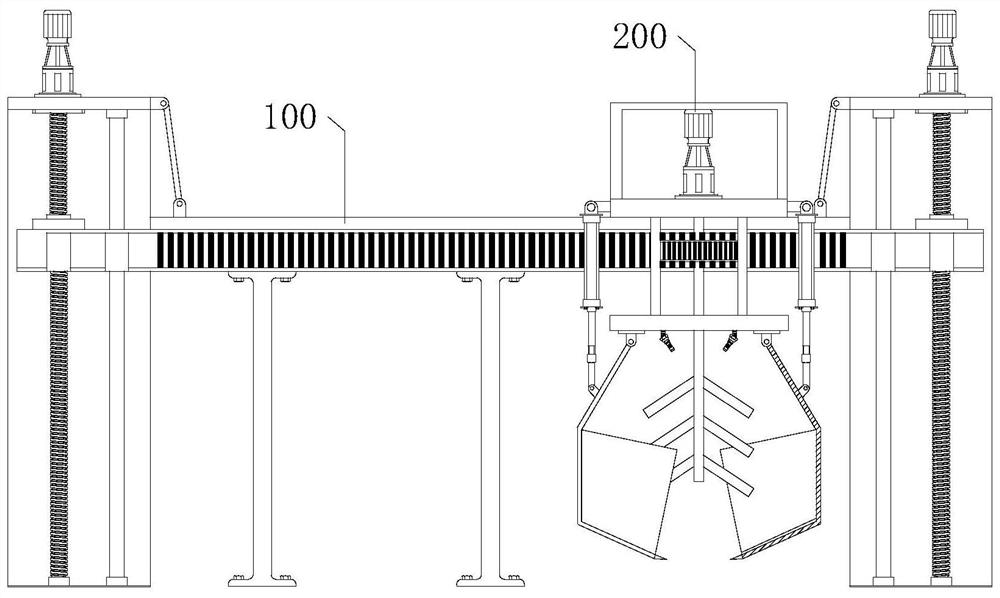

[0030] see figure 1 , the present invention provides a technical solution: a remote construction concrete reclaiming device, including a lifting mechanism 100 and a retrieving and conveying mechanism 200 .

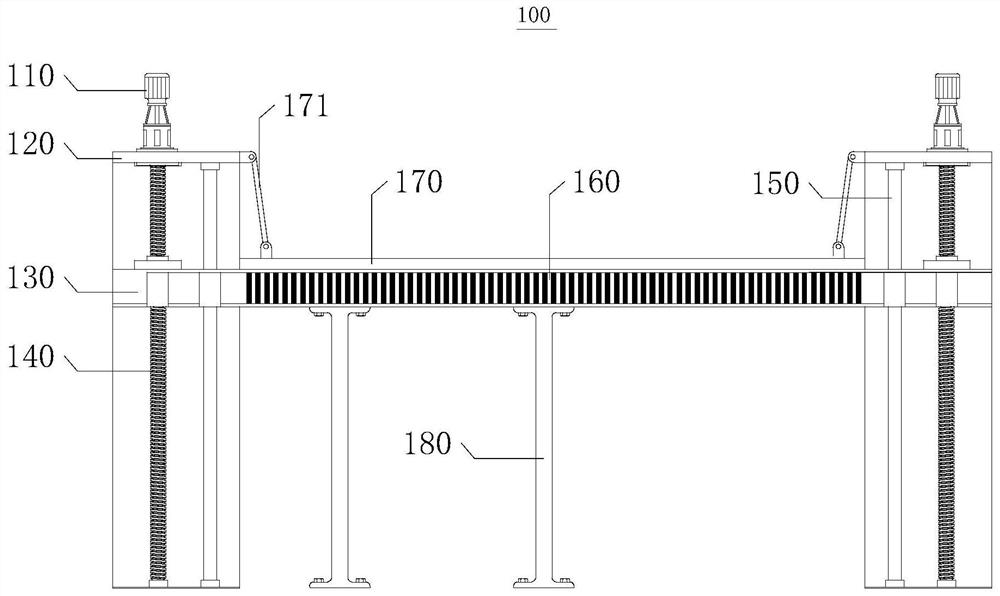

[0031] see figure 2 , the lifting mechanism 100 includes a first motor 110, a mounting frame 120, a first mounting plate 130, a screw mandrel 140, a rack 160, and a support plate 170, the first motor 110 is fixedly installed on the top of the mounting frame 120, and the first mounting plate 130 Slidingly connected with the side wall of the mounting frame 120, the screw rod 140 is threaded through the first mounting plate 130 and connected with the output shaft key of the first motor 110, the rack 160 is fixedly installed on the first mounting plate 130, and the support plate 170 is fixedly installed on the Mounting frame 120 .

[0032] see figure 2 , The lifting mechanism 100 also includes a support column 180, which is fixedly installed on the bottom of the first ins...

Embodiment 2

[0043] see figure 1 , the present invention provides a technical solution: a remote construction concrete reclaiming device, including a lifting mechanism 100 and a retrieving and conveying mechanism 200 .

[0044] see figure 2 , the lifting mechanism 100 includes a first motor 110, a mounting frame 120, a first mounting plate 130, a screw mandrel 140, a rack 160, and a support plate 170, the first motor 110 is fixedly installed on the top of the mounting frame 120, and the first mounting plate 130 Slidingly connected with the side wall of the mounting frame 120, the screw rod 140 is threaded through the first mounting plate 130 and connected with the output shaft key of the first motor 110, the rack 160 is fixedly installed on the first mounting plate 130, and the support plate 170 is fixedly installed on the Mounting frame 120 .

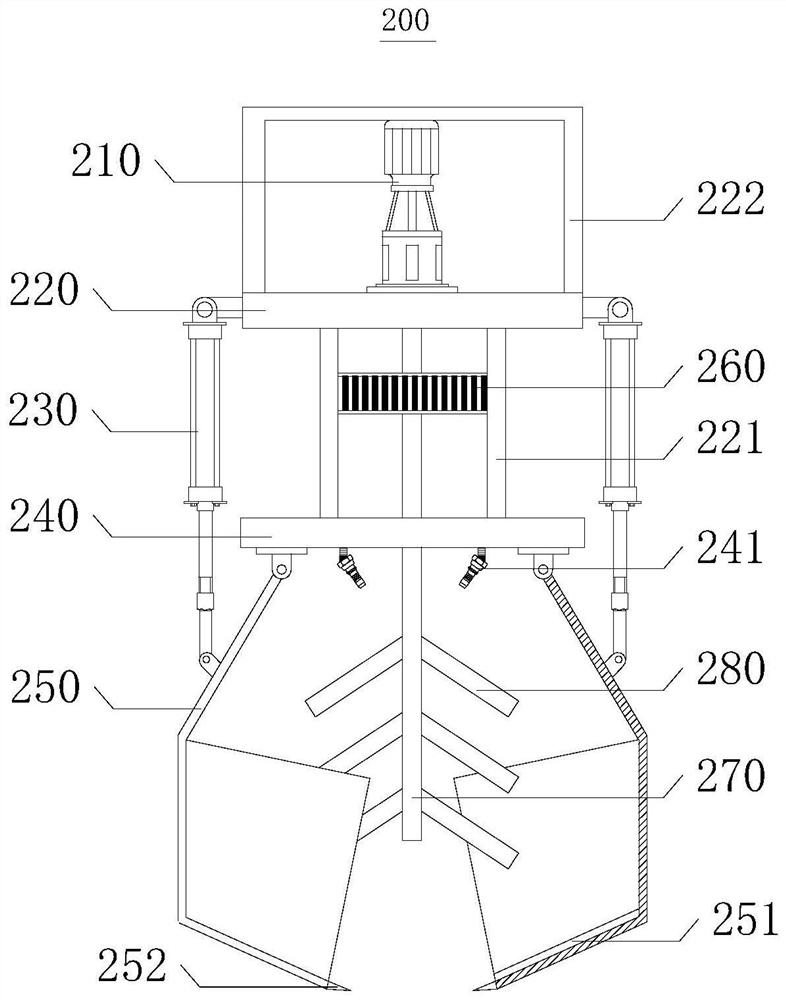

[0045] see image 3 , the feeding conveying mechanism 200 includes a second motor 210, a second mounting plate 220, a connecting rod 221, a cy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com