High-load file robot based on flexible manipulator

A manipulator, high-load technology, applied in the direction of manipulators, program-controlled manipulators, conveyor objects, etc., can solve the problems of high construction intensity, chaotic management, and large volume on site

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

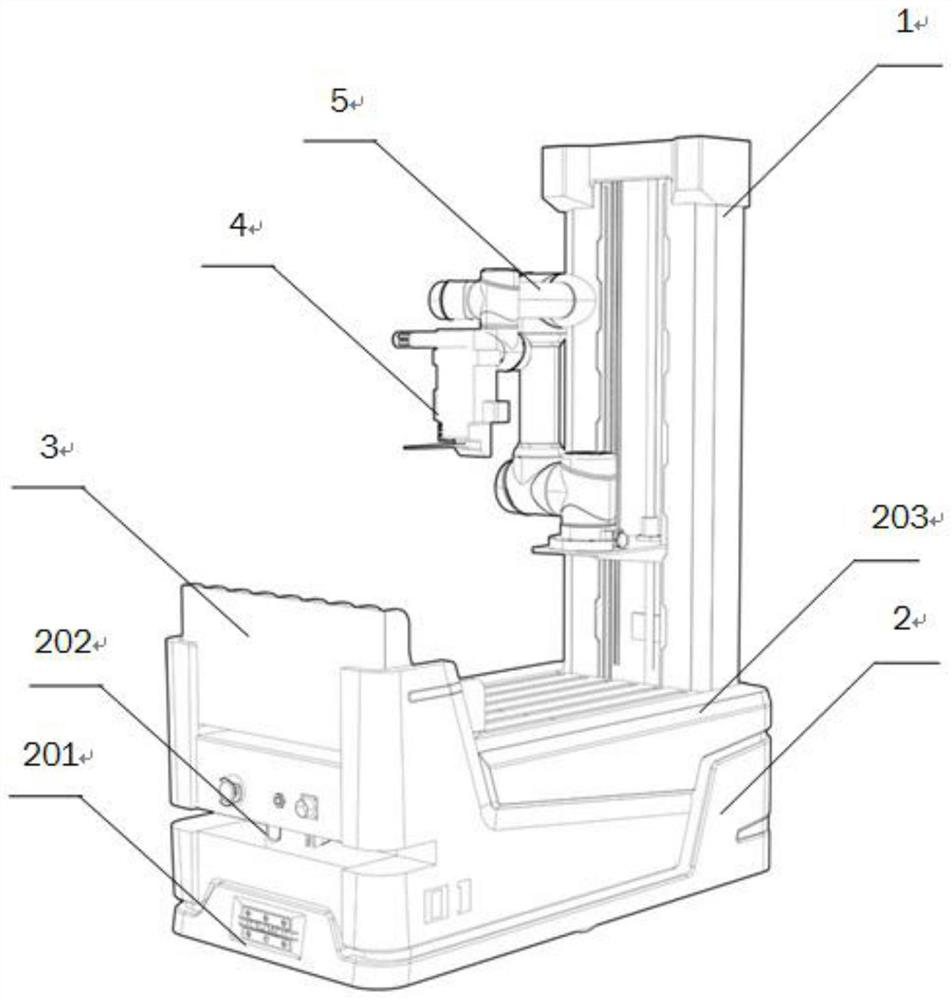

[0024] like Figure 1-7 Shown is a high-load file robot based on a flexible manipulator, mainly composed of 5 cooperative arms, 2 intelligent mobile platforms, 4 mechanical grippers, 1 lifting mechanism, and 3 buffer bins, which are characterized in that:

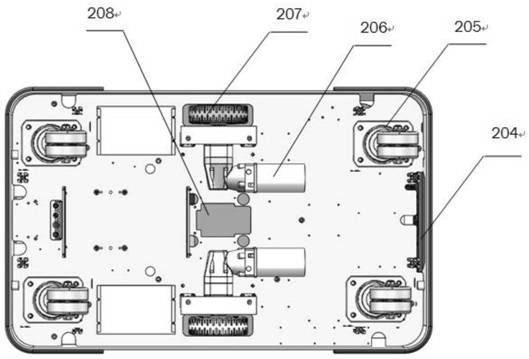

[0025] The 2 intelligent mobile platforms include: 201 charging device, 202 laser radar sensor, 203 LED indicator module, 204 anti-collision strip, 205 universal driven wheel, 206 power source, 207 driving wheel, 208 PVG position guidance visual system. Among them, the 201 charging device is installed on the side of the 2 intelligent mobile platform, which is mainly convenient to contact with the charging shrapnel of the charging pile to realize charging; the 202 laser radar sensor is installed above the 201 charging device, which is used to collect the scene environment, build a SLAM map, and drive the path Planning and navigation; 2 207 driving wheels are designed in the middle of the bottom of the intelligent mobile plat...

Embodiment 2

[0030] Described a kind of high-load filing robot based on flexible manipulator uses method as follows:

[0031] (1) When the archive robot is placed in a new archive room, the on-site environment is collected first, and the on-site map is constructed through the laser radar installed on the archive robot;

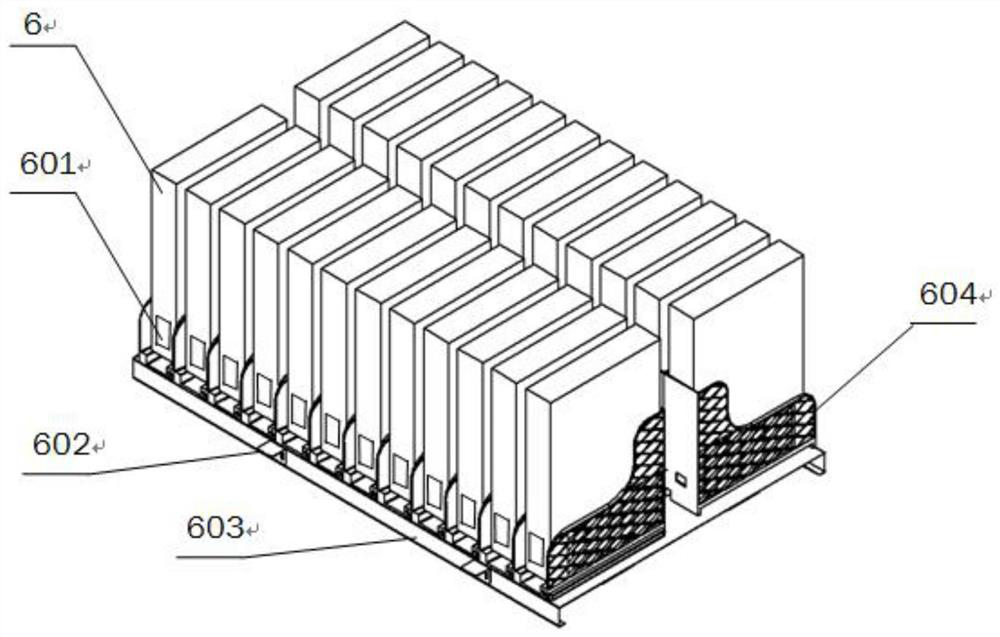

[0032] (2) When the file robot receives a new task, it first moves according to the issued planning path, uses laser SLAM navigation outside the file rack, and uses two-dimensional code inertial navigation inside the file rack;

[0033] (3) Since the laser SLAM navigation accuracy cannot meet the accuracy required for the final visual positioning of the end of the robotic arm, a Pepperl+Fuchs PGV sensor will be installed in the middle of the smart mobile platform, which will be connected to the controller through 485 communication. When the smart mobile platform ends After laser positioning and navigation, according to the QR code data pasted on the ground scanned by the Q...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com