A machined surface roughening milling cutter and a machined surface processing method thereof

A surface roughening and milling cutter technology, applied in milling cutters, metal processing equipment, milling machines, etc., can solve the problems of insufficient roughening degree, time-consuming machining of surface roughening, and difficulty in achieving adhesion. Good effect, high roughness, high feed speed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

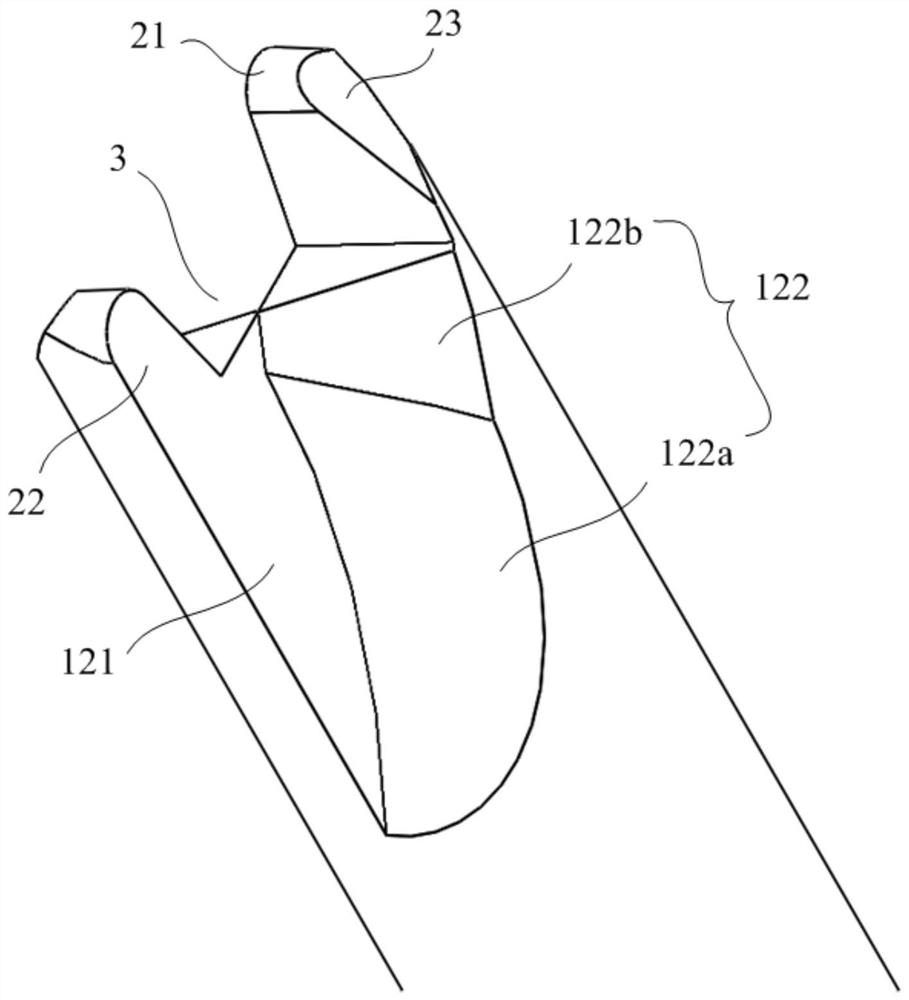

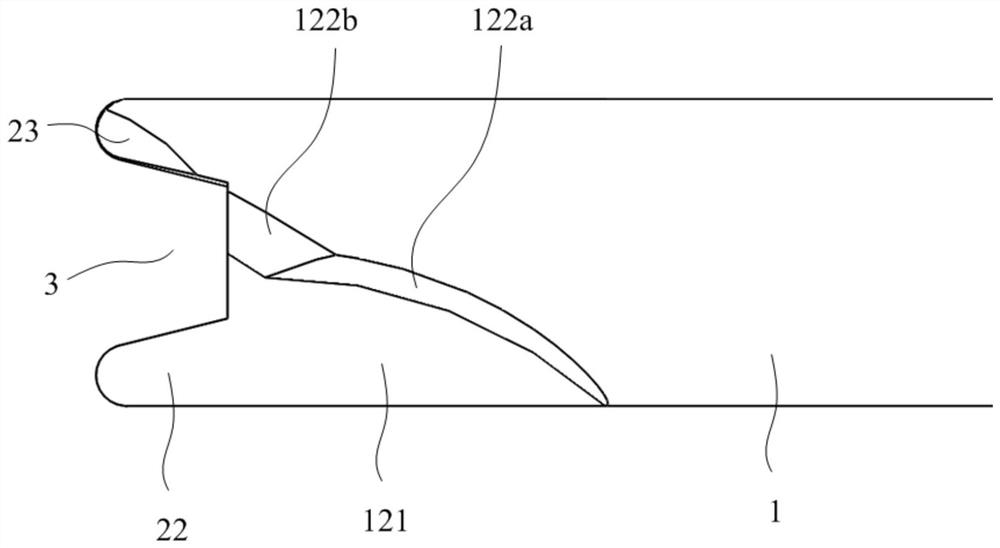

[0030] like figure 1 , figure 2 , image 3 and Figure 4 As shown, this embodiment provides an embodiment of a machined surface roughening milling cutter, including a cutter body 1 and at least two cutter teeth 2, the cutter teeth 2 are formed at the end of the cutter body 1, and the cutter An avoidance groove 3 is formed between the teeth 2 and the end face 11 of the cutter body, and a chip removal groove 12 communicating with the avoidance groove 3 is formed on the outer periphery of the cutter body 1; wherein, the width of the end face 21 of the cutter tooth is 0.3- 1.1mm; the height of the cutter teeth 2 is 1.5-3.8mm; the relief groove 3 is open to the cutter tooth end face 21 side, and the ratio of the width of the groove bottom of the relief groove 3 to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com