Fresh rice freezing and hulling device

A technology for rice and fresh food, which is applied in the fields of grain shelling, grain processing, application, etc., can solve the problems of reducing the quality of fresh rice processing and the inability of fresh rice to be fully shelled.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

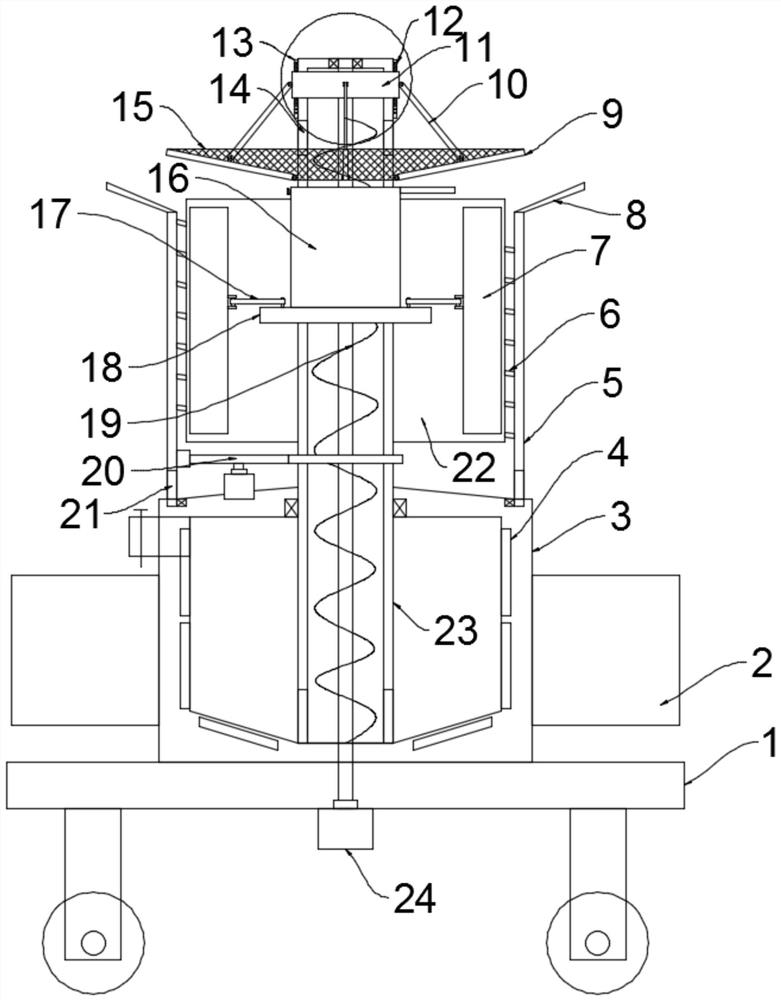

[0027] see Figure 1~2 , in an embodiment of the present invention, a fresh rice frozen shelling device includes a shelling unit, and also includes a freezing unit, and a conveying unit for transporting grains is connected between the freezing unit and the shelling unit, and the shelling unit The shell unit includes an inner cylinder 22 and an outer cylinder 5 that rotate in reverse. Between the cylinders 22, there is a spiral bar 6, which is spirally arranged from top to bottom, and the spiral bar 6 is fixedly connected with the inner wall of the outer cylinder 5. When working, the outer cylinder 5 and the inner cylinder 22 are used to rotate in reverse , grinding and shelling the grains entering between the two, the shelling section is in a vertical cylindrical shape, the number of shelled grains is large, and the work efficiency is improved. Grinding and shelling, through the setting of the spiral bar 6, the speed of grain movement is delayed, ensuring that the grains can ...

Embodiment 2

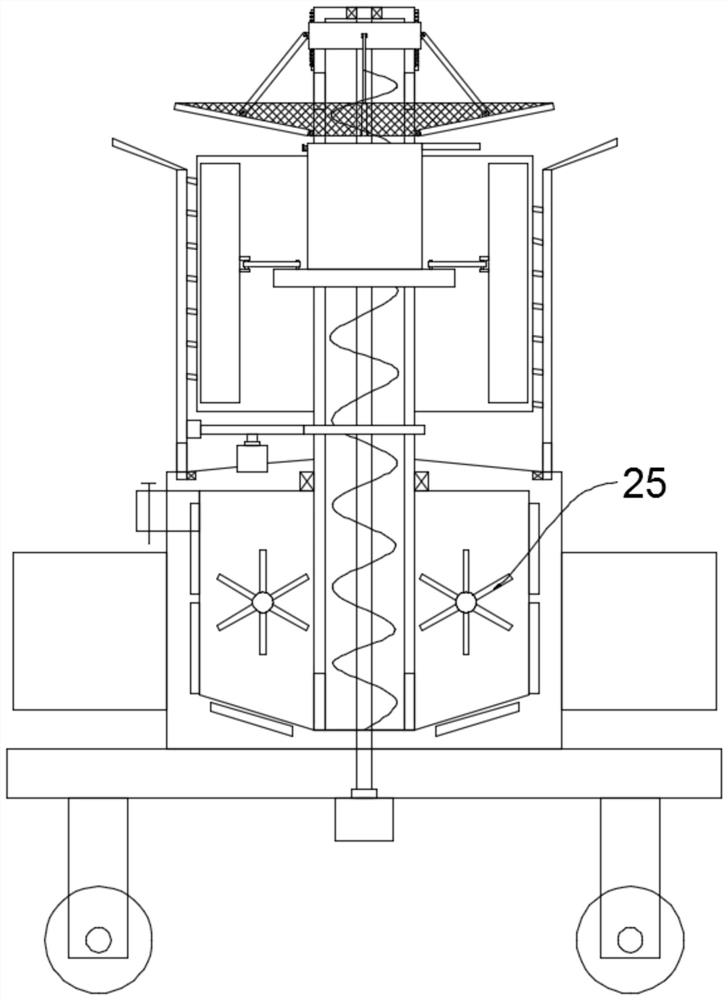

[0033] see image 3 The difference between this embodiment of the present invention and Embodiment 1 is that a stirring mechanism 25 is installed in the freezing cylinder 3, so that the grains are frozen more fully and evenly.

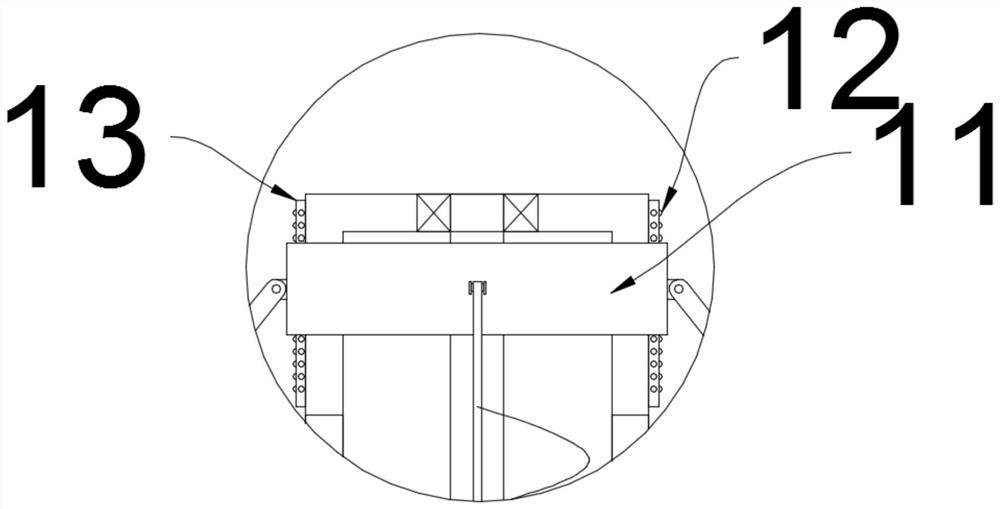

[0034] The working principle of the present invention is: when working, the frozen grains in the freezing cylinder 3 enter the lifting cylinder 23, are lifted upwards under the action of the lifting auger 19, and are discharged through the first discharge port 14, and the grains in the first discharge port 14 It falls on the elastic support net 15, moves outwards evenly along the elastic support net 15 under centrifugal force, and then falls evenly from the edge. By manually adjusting the position of the adjustment sleeve 11, the adjustment sleeve 11 drives the installation rod through the first connecting rod 10 9 rotates, adjusts the inclination angle of installation bar 9 and elastic support net 15, adjusts the movement speed of grain, and then adju...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com