Blast furnace fly ash treatment device and using method thereof

A blast furnace dust removal and processing device technology, applied in chemical instruments and methods, transportation and packaging, chemical/physical processes, etc., can solve the mixing of granular coke powder and dust removal powder, uneven heating of coke powder and dust removal powder, Difficult to control the timing of feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

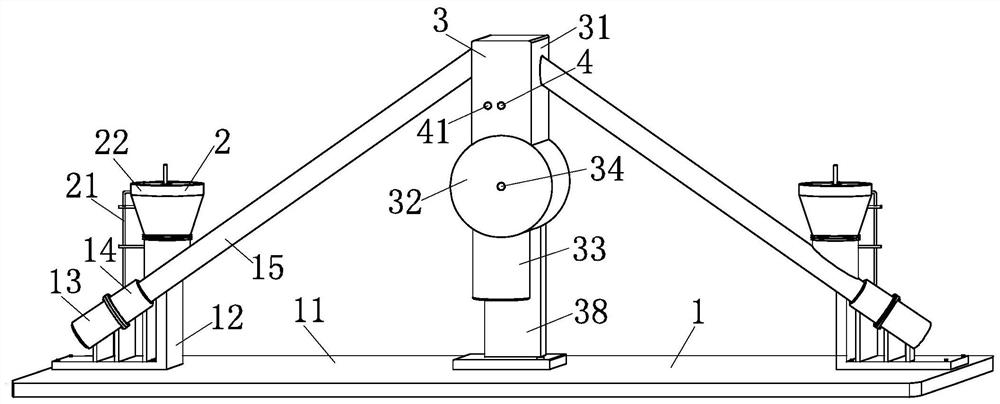

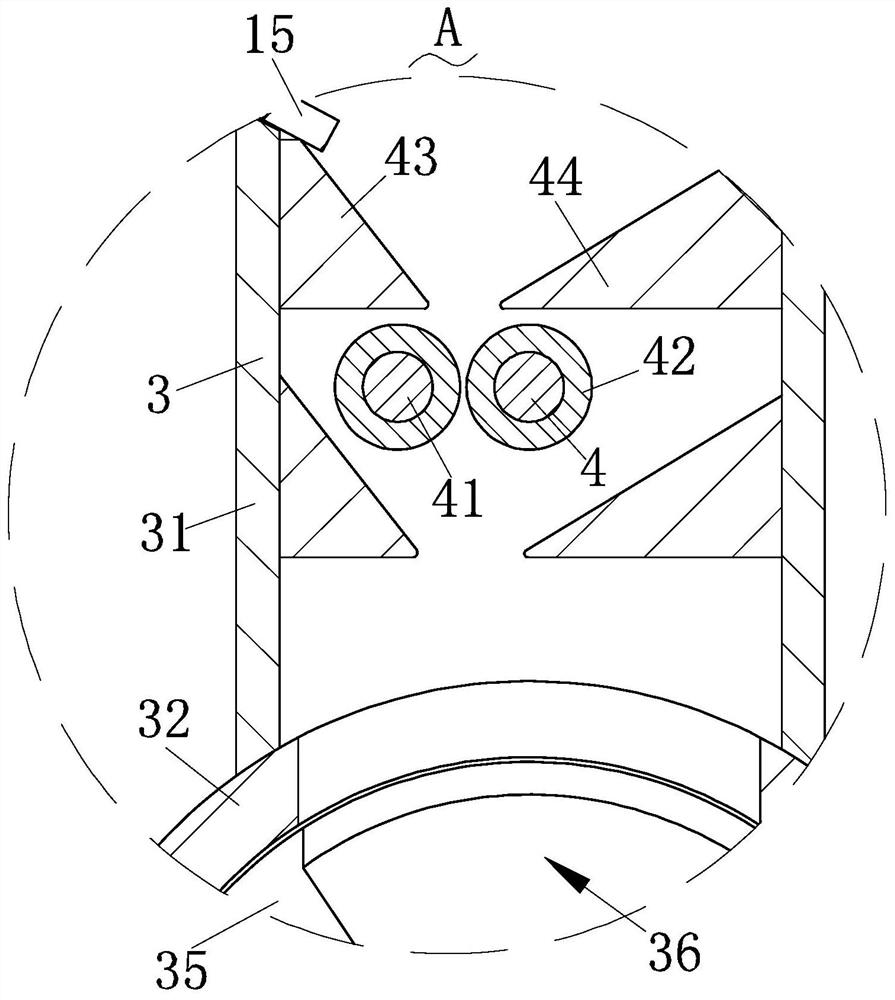

[0030] Such as Figure 1-7As shown in the figure, a blast furnace dedusting ash processing device according to the present invention includes two feeding mechanisms 1, two storage mechanisms 2, a feeding mechanism 3 and a rolling mechanism 4, which are used to realize coking powder and dust removal powder. The bottoms of the two storage mechanisms 2 for storing and shaking are connected with the feeding mechanism 1 for feeding the focusing powder and dedusting powder, and the tops of the two charging mechanisms 1 are connected with the charging mechanism for focusing powder. Mix with dedusting powder, the described unloading mechanism 3 of timing unloading, the inside of described unloading mechanism 3 is equipped with the described rolling mechan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com