Computer case paint mixing and stirring device and operation method

A mixing and stirring, computer technology, applied in mixers, chemical instruments and methods, shaking/oscillating/vibrating mixers, etc., can solve the safety hazards that affect the surface effect of computer chassis, paint volatilization and splashing, and cannot be sealed and prevented. dust, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below according to accompanying drawing and embodiment the present invention will be described in further detail:

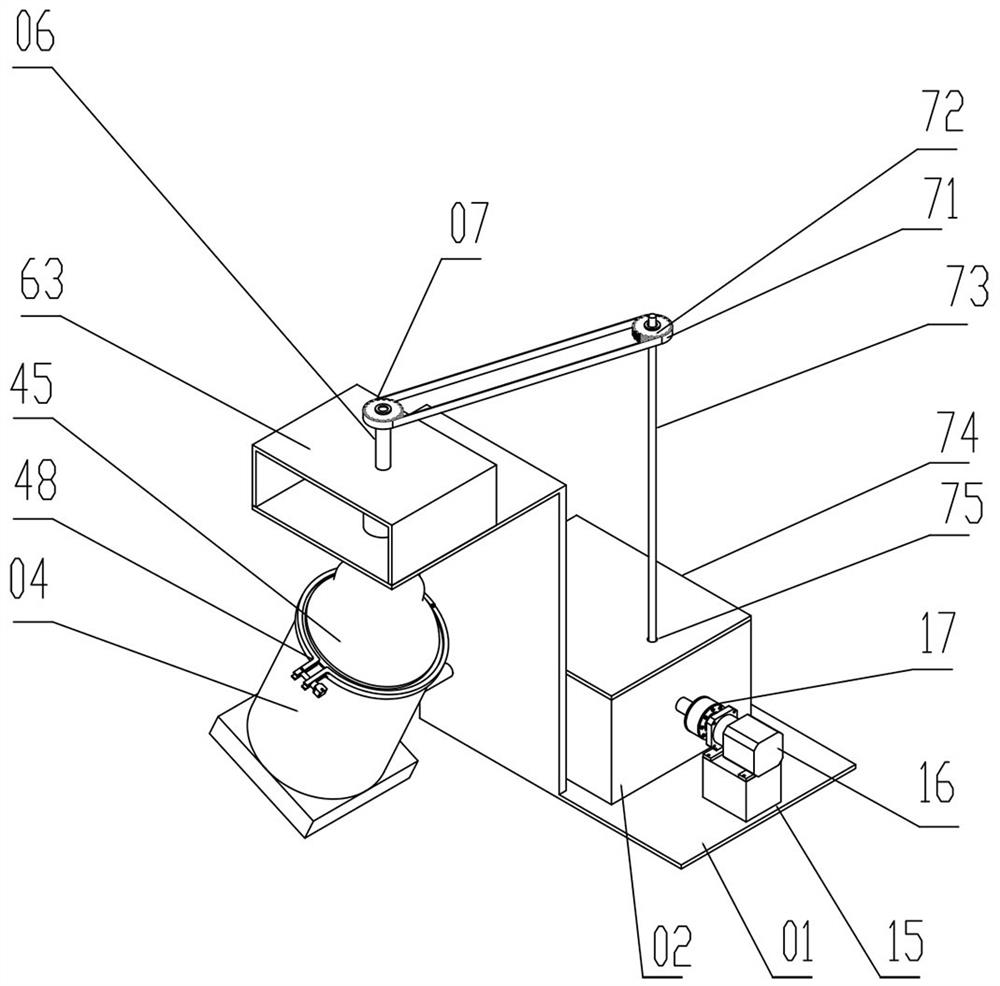

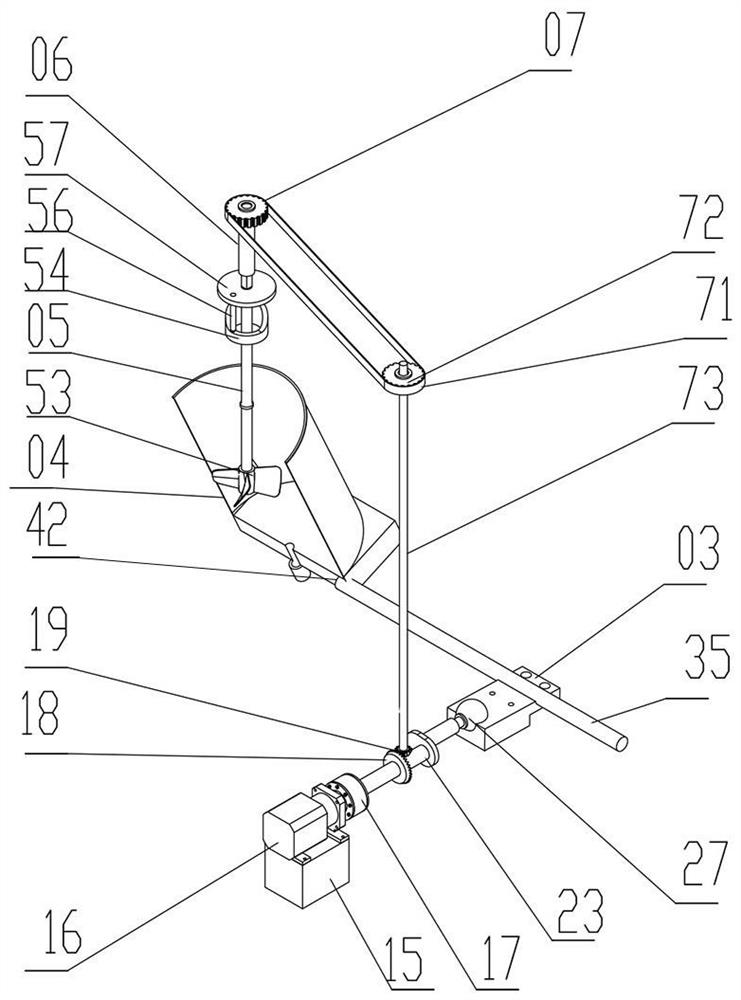

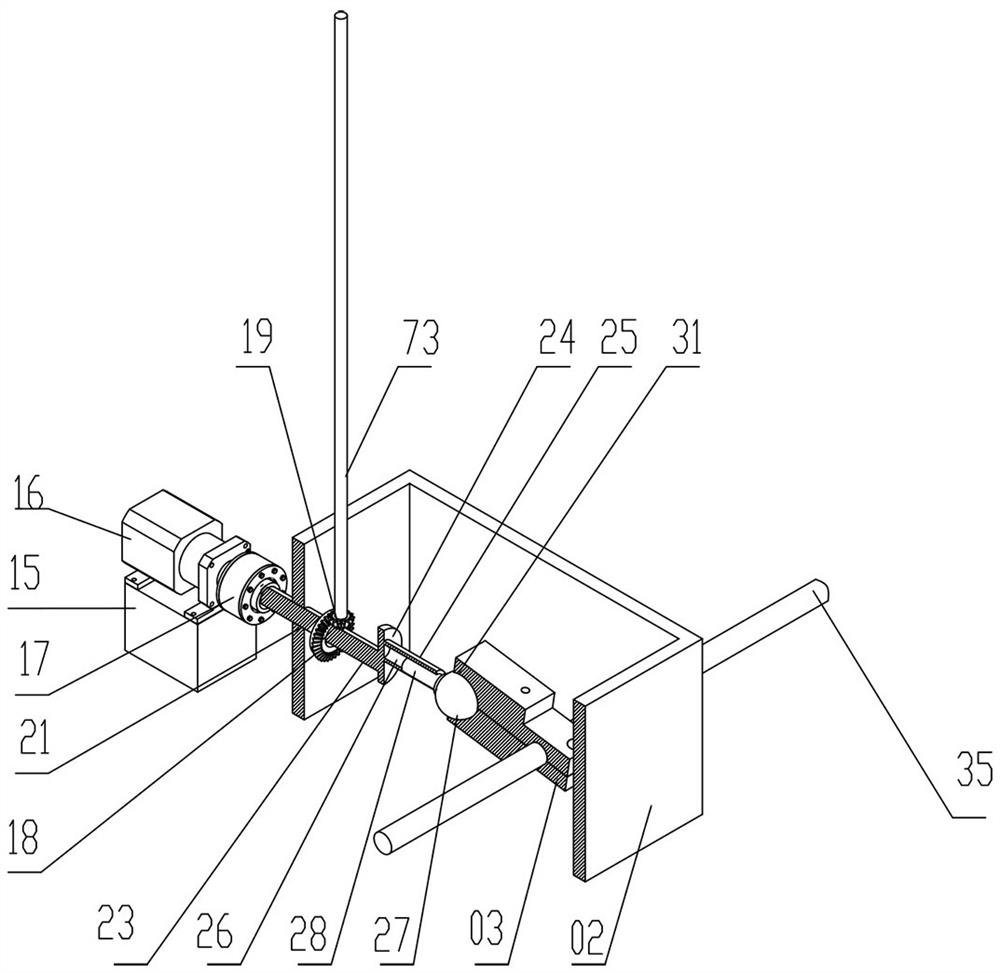

[0021]A paint mixing and stirring device for a computer case, comprising a base 01, a motor 16, a coupling 17, a No. 1 bevel gear 18, a No. 2 bevel gear 19, a case 02, a right axle block 25, a ball head 27, a ball head seat 03, Output shaft 35, paint bucket 04, bucket cover 45, clamp 48, stirring shaft 05, blade 53, cam 54, transmission shaft 06, No. 1 synchronous wheel 07, synchronous belt 71, No. 2 synchronous wheel 72, transmission shaft 73, The right side of the base 01 is fixedly connected to the motor base 15, and the upper part of the motor base 15 is fixedly connected to the motor 16. The motor 16 is fixedly connected to the crankshaft 23 through a coupling 17. The outer side of the crankshaft 23 is provided with a chassis 02. The left side of the chassis 02 has a crankshaft hole 21 and a crankshaft hole 21 Rotationally connected crankshaft 23, cra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com