A motor rotor shaft sleeve assembly machine

A technology of motor rotor shaft and motor rotor, which is applied in the manufacture of stator/rotor body, etc., can solve the problems of low production efficiency, inability to ensure that the shaft sleeve is in place, and cannot meet the simultaneous pressing of two axes, and achieve low cost, simple structure, and prevent The effect of crushing the bushing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

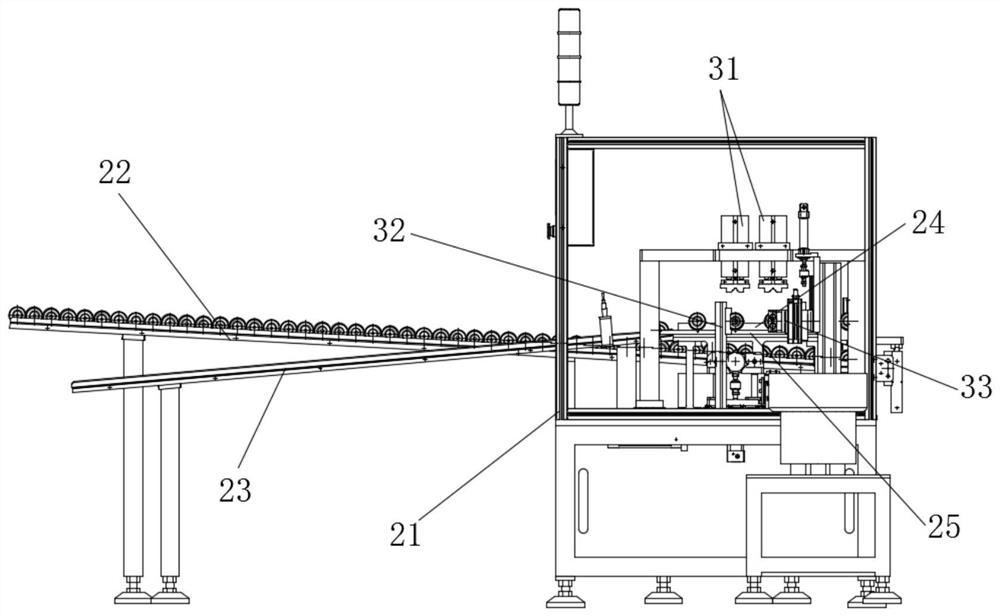

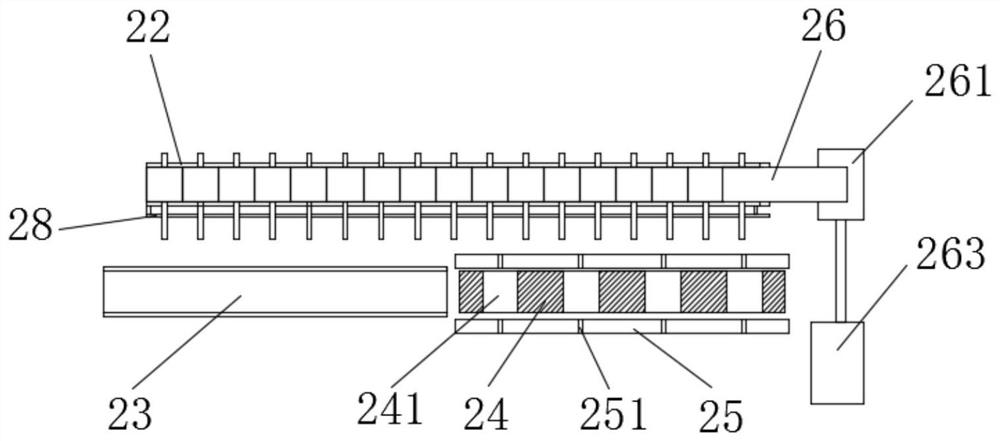

[0039] This embodiment proposes a motor rotor shaft sleeve assembly machine, refer to figure 1 Including the frame 21, the motor rotor positioning block 24 is fixed on the frame 21, the two sides of the motor rotor positioning block 24 are symmetrically provided with a shaft sleeve inserting device 33 and a shaft sleeve pressing device 32, and the motor rotor positioning block 24 is provided with a motor rotor Compression block 31, the motor rotor compression block 31 is used to compress the motor rotor positioned on the motor rotor positioning block 24, and the shaft sleeve inserting device 33 is used to grab the shaft sleeve and initially insert the shaft sleeve into the shaft of the motor rotor , the sleeve press-in device 32 is used to press the initially inserted sleeve to a designated position, the frame 21 is also provided with a motor rotor transmission device and a motor rotor sleeve option device, and the motor rotor transmission device is used for motor rotor transm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com