Ultrasonic damage judging method and system for embedded part of train axle

A technology for train axles and train wheels, applied in image data processing, instruments, calculations, etc., can solve the problems of low reliability of detection results, achieve the effects of enhancing target defect characteristics, improving accuracy, and solving low reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

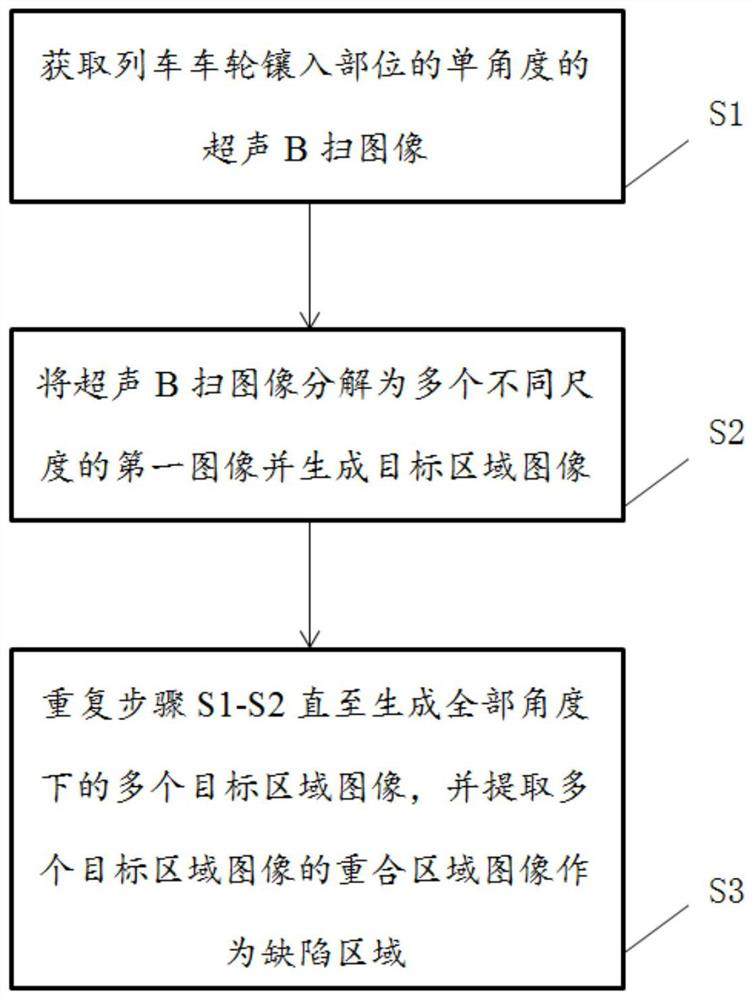

[0019] Such as figure 1 As shown, a method for ultrasonic diagnosis of the embedded part of the train axle, including:

[0020] S1: Obtain a single-angle ultrasonic B-scan image of the train wheel inlay. Wherein, after obtaining the single-angle ultrasonic B-scan image of the part inserted by the train wheel, the size uniform processing is performed on the ultrasonic B-scan image.

[0021] S2: Decompose the ultrasound B-scan image into a plurality of first images of different scales, calculate the saliency value of each pixel block in the plurality of first images, and generate a target area image.

[0022] Further, the S2 includes: S21: Decompose the ultrasonic B-scan image into a plurality of first images of different...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com