Preparation method of fluorescence sensor for Cr (VI) real-time detection and product produced thereby

A technology for fluorescent sensors and membranes, applied in nanotechnology for sensing, chemical instruments and methods, fluorescence/phosphorescence, etc., can solve the problem of carbon dot shedding, affecting the stability of detection results, and the failure of fluorescent sensors to realize recycling, etc. problem, to achieve the effect of improved sensitivity, high selectivity and sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

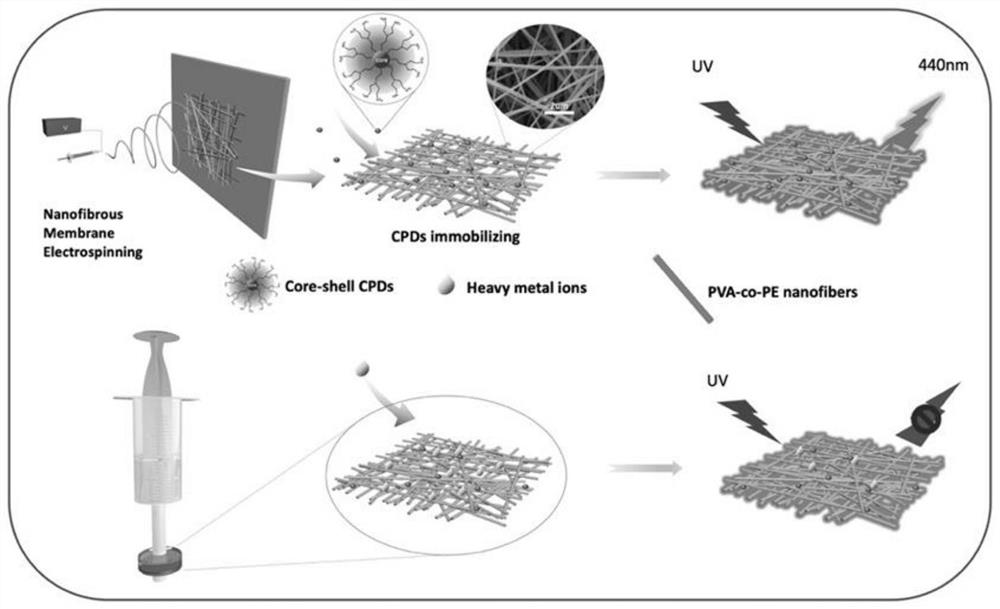

Method used

Image

Examples

Embodiment 1

[0032] (1) Dissolve N,N'-succinimidyl carbonate (DSC) in 1,4-dioxane, the concentration range is 1wt.%, and add a small amount of triethylamine (TEA), the addition amount is 0.5wt.%;

[0033] (2) The PVA-co-PE nanofiber film prepared by electrospinning process, the spinning process is: voltage 20kV, concentration 10%, spinning length 15cm, spinning speed is 1mL / h; PVA-co-PE nanofiber Add the membrane to the solution of (1) above, heat and slowly stir to react, the stirring speed is 150rpm, the heating temperature is 60°C, and the stirring reaction time is 2h to prevent the membrane from breaking;

[0034] (3) After the reaction is completed, the membrane is fully washed with 1,4-dioxane, and dried at 50°C for later use;

[0035] (4) Dissolve a certain amount of carbon dot powder in deionized water at a concentration of 0.2g / L; immerse the activated PVA-co-PE nanofiber membrane in the carbon dot solution, and slowly stir the reaction at a reaction temperature of 70°C. Reactio...

Embodiment 2

[0038] (1) Dissolve N,N'-succinimidyl carbonate (DSC) in 1,4-dioxane at a concentration range of 2.5wt.%, and add a small amount of triethylamine (TEA). 0.5wt.%;

[0039] (2) The PVA-co-PE nanofiber film prepared by electrospinning process, the spinning process is: voltage 20kV, concentration 10%, spinning length 15cm, spinning speed is 1mL / h; PVA-co-PE nanofiber Add the membrane to the solution of (1) above, heat and slowly stir to react, the stirring speed is 150rpm, the heating temperature is 60°C, and the stirring reaction time is 2h to prevent the membrane from breaking;

[0040] (3) After the reaction is completed, the membrane is fully washed with 1,4-dioxane, and dried at 50°C for later use;

[0041] (4) Dissolve a certain amount of carbon dot powder in deionized water at a concentration of 0.2g / L; immerse the activated PVA-co-PE nanofiber membrane in the carbon dot solution, and slowly stir the reaction at a reaction temperature of 70°C. Reaction time 120min;

[0042...

Embodiment 3

[0044] (1) Dissolve N,N'-succinimidyl carbonate (DSC) in 1,4-dioxane, the concentration range is 5wt.%, and add a small amount of triethylamine (TEA), the addition amount is 0.5wt.%;

[0045] (2) The PVA-co-PE nanofiber film prepared by electrospinning process, the spinning process is: voltage 20kV, concentration 10%, spinning length 15cm, spinning speed is 1mL / h; PVA-co-PE nanofiber Add the membrane to the solution of (1) above, heat and slowly stir to react, the stirring speed is 150rpm, the heating temperature is 60°C, and the stirring reaction time is 2h to prevent the membrane from breaking;

[0046] (3) After the reaction is completed, the membrane is fully washed with 1,4-dioxane, and dried at 50°C for later use;

[0047] (4) Dissolve a certain amount of carbon dot powder in deionized water at a concentration of 0.2g / L; immerse the activated PVA-co-PE nanofiber membrane in the carbon dot solution, and slowly stir the reaction at a reaction temperature of 70°C. Reactio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com