Full-automatic dilution instrument and liquid dilution method

A diluter, fully automatic technology, applied in the field of detection, can solve the problems of accuracy of liquid taking, normative error of liquid addition, non-traceability of dilution process, deviation of test results, etc., to ensure accuracy and avoid dilution efficiency. Low, avoid cross-contamination effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

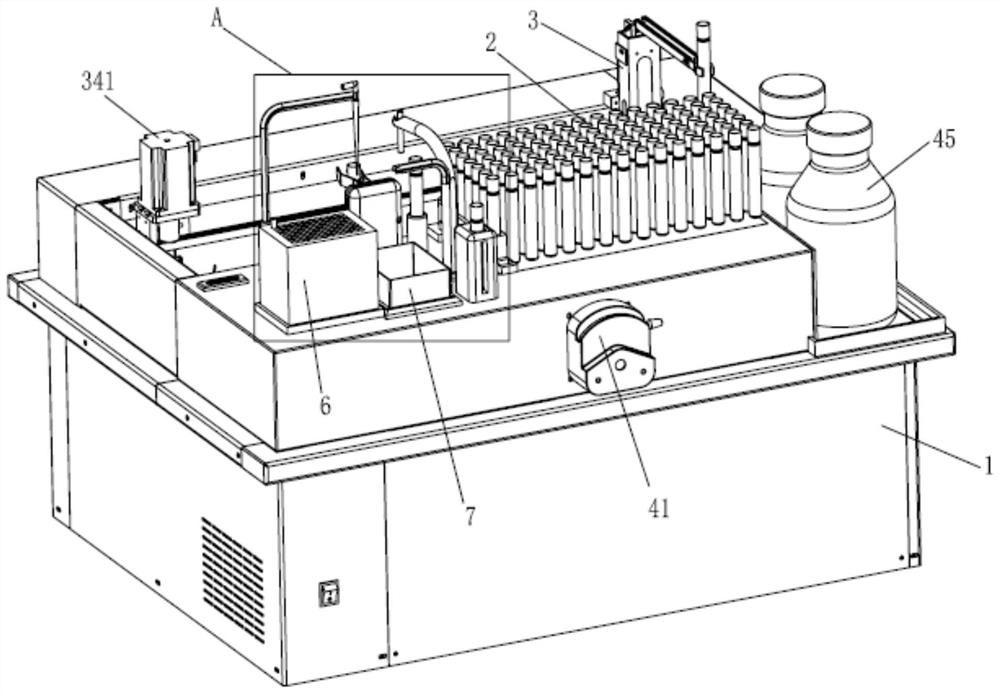

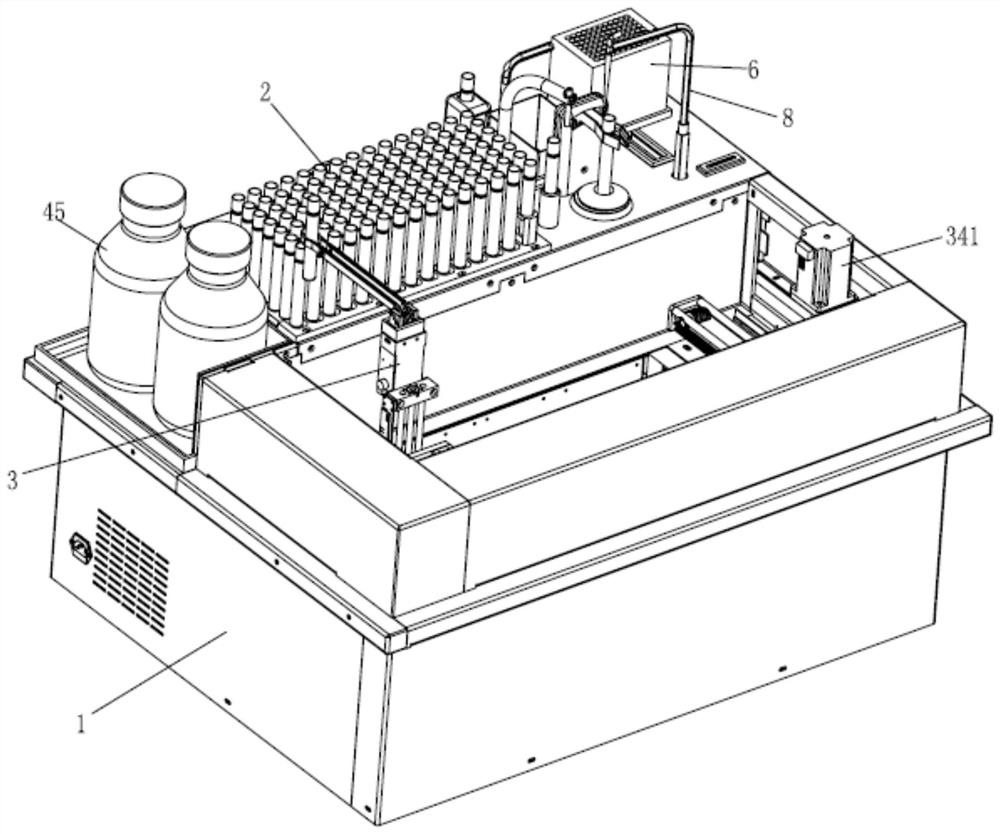

[0079] Such as figure 1 , 2 As shown, the fully automatic diluter of the present invention includes a workbench 1, a container placement area arranged on the workbench 1, the container placement area is provided with a plurality of container positions for placing containers 2, the fully automatic diluter of the present invention The diluter also includes the following components connected to the workbench 1:

[0080] Manipulator 3 for transferring container 2;

[0081] Liquid injection device, for injecting quantitative diluent into the container transferred by the manipulator 3;

[0082] Mixing device 5, used to mix the liquid in the container;

[0083] The pipette tip receiving device 6 for holding the tip of the pipette for use 7;

[0084] Pipette gun device 8, which can be detachably connected with the ready-to-use pipette tip 7 in the ready-to-use pipette tip accommodation device 6, the tip 7 absorbs the quantitatively mixed liquid from the mixed liquid After the liq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com