Fully distributed pipeline erosion monitoring system and method based on optical fiber sensing

A fully distributed, optical fiber sensing technology, applied in measuring devices, measuring heat, using optical devices, etc., can solve problems such as difficulty in identifying the thinning of the protective layer of the pipeline covering soil, difficult to achieve full coverage monitoring, and accuracy impact. Achieve the effect of low cost, easy installation and convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0034] Embodiment: In this embodiment, the soil in which the pipeline 1 and the two temperature sensing optical cables are buried is clay.

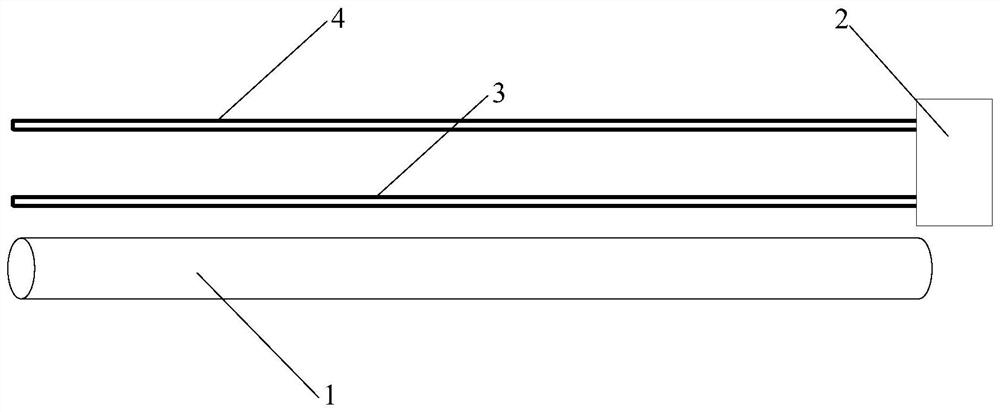

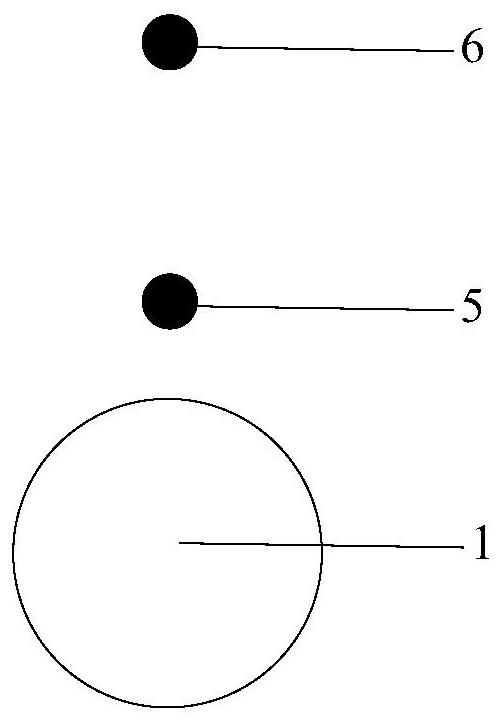

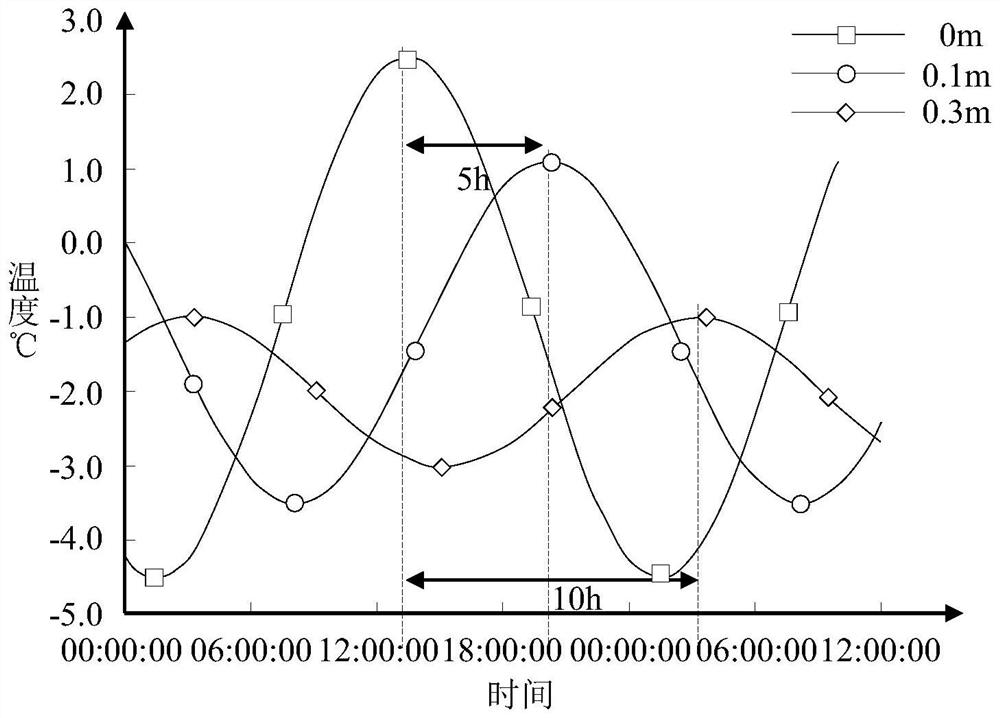

[0035] like image 3 As shown, the three soil depths from the ground in the same vertical direction are set to be 0m, 0.1m and 0.3m, and the temperature-time curves of the three soils at 0m, 0.1m and 0.3m all show periodicity The law of change. Compared with the temperature-time curve at the burial depth of 0m, the phase differences between the 0.1m and 0.3m curves are 5 and 10h respectively, that is, the difference in burial depth is different, and the phase difference is also different. Therefore, by burying the temperature sensing optical cable at the pipeline 1 to be tested and the temperature sensing optical cable at the reference point above, the erosion of the soil on the surface of the pipeline 1 can be judged by the change of the phase difference of the two temperature-time curves. And because the external heat source changes c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com